A magnetic drum separator removes ferrous metal from dry, free-flowing bulk solids. It is self-cleaning and available within a housing or as the magnetic drum only.

NEED HELP FAST? We have over 40 years' experience with Bulk Material Handling, Packaging, and Processing. (979) 217-1480 GET A QUOTE

NEED HELP FAST? (979) 217-1480 GET A QUOTE

Category | Magnetic Separation |

A magnetic drum separator removes ferrous metal from dry, free-flowing bulk solids. It is self-cleaning and available within a housing or as the magnetic drum only.

Category | Magnetic Separation |

An eddy current separator can achieve up to 97% metal recovery rates from waste streams in MRFs, C&D recycling systems, auto shredding processes, glass removal operations, electronics recycling and more.

Category | Magnetic Separation |

Rotary grate magnets remove ferrous metal from dry powders and other bulk solids that have poor flow characteristics. These types of solids also have a tendency to bridge and choke, when using stationary tube style magnetic separators. Sizes range from 8″ by 8″ up to 18″ by 18″ outlets with custom designs available to fit your exact specifications.

Category | Magnetic Separation | Recycling Systems |

Large tube magnets used for paper recycling

Magnets, such as these large tube rare earth magnets, are used inside of recycling systems that process recoverable materials like paper. This type of magnet would be installed after the paper shredding step inside of the recycling stream. The magnets catch stray nuts, bolts, staples, paper clips, and other metal objects before they reach downstream grinding equipment. They also collect fine metallic particles to ensure a metal-free, recycled paper product. Removal of the collected metals is accomplished using the EZ-clean and self-cleaning design on the magnet.

Category | Magnetic Separation | Recycling Systems |

This video shows a magnetic drum that removes ferrous metal from a recycling system. These rugged types of magnetic separators have a heavy-duty manganese wear shell that protects against damage from large or sharp objects.

Category | Valve Bag Fillers |

First, an empty valve bag is placed on the valve bagging machine spout. During the fill cycle, the low frequency oscillating (or reciprocating) densifier is activated to settle and densify the material inside the valve bag. This allows for complete filling of the bag to reach a set point weight. Other types of densifiers are also available.

Ask a Question or Get a Price Quote

Category | Bag Handling Conveyors |

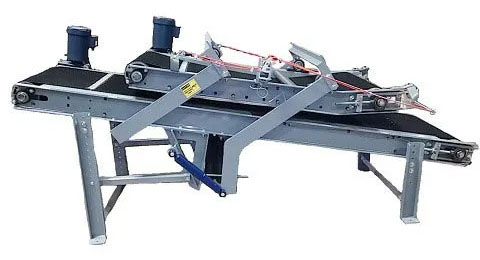

A bag flattener conveyor is designed for flattening both filled valve bags and open mouth bags to make them more uniform in shape to stack on a shipping pallet. They are flattened as they move through two conveyors with the upper conveyor applying adjustable force to the top of the bag. Typically, the bag flattener also acts as an incline conveyor that elevates the bags to the inlet of a palletizing station.

Category | Bag Sewing Machines and Heat Sealers | Valve Bag Fillers |

An ultrasonic valve bag sealer is a specialized piece of equipment designed to provide a clean and efficient solution for sealing valve bags. The process involves sealing the bag before it is discharged onto a conveyor, which minimizes product spillage and migration to the surrounding environment. The sealer hermetically seals filled bags with an ultrasonically sealable valve sleeve, ensuring a high level of cleanliness during operation.

Watch a Demonstration Test Video

An auger filler integrated with an ultrasonic valve bag sealer is a versatile machine that can bag and seal a variety of powders, especially those requiring quick cleanout between packaging runs. The machine shown in the video is ideal for sanitary uses or for any application where cross-contamination must be prevented. It uses an auger to fill valve bags with powdery products and ultrasonic technology to close and discharge the bags.

This type of auger filler is designed to handle a bag filling weight range of 20-110 lbs. and can achieve a production rate of 1-3 bags per minute, depending on the material and bag size. It can accommodate a material density range of 20-75 lbs. per cubic foot. The auger filling machine can operate in semi-automatic (operator-assisted) or fully automatic modes and is compatible with sonic sleeve paper and plastic film bag types. After filling and sealing, the bags drop onto a wire mesh discharge conveyor and then move toward a manual palletizing or robotic palletizing system.

Examples of materials that can be bagged with this machine include flour, bakery mixes, cocoa, spices, pepper, animal grade pharmaceuticals, and nutraceuticals. The interior moving parts, such as the auger and agitator blades, can be easily removed for cleaning and inspection, making it a practical choice for industries that need to switch between different products frequently.

Ask a Question or Get a Price Quote

Call: (979) 217-1480

Category | Bag Sewing Machines and Heat Sealers |

This simple, economical bag sealing system allows a single operator to fill and heat seal up to 4 plastic or foil bags per minute. The bagging system includes an 8 foot long bag closing conveyor, a clamp type heat sealer with mounting pedestal, and variable speed bag indexing controls to control the speed of the filled bag on the take away conveyor.

The filled bag heat sealing system can be used with most of the open mouth baggers that we sell.

Category | Bulk Processing Equipment | Small Vibratory Feeders | Vibration Tables |

This box filling machine fills empty boxes with chopped metal fibers by weight. The metal fibers are added to concrete to increase its strength.

Category | Magnetic Separation | Recycling Systems |

A self-cleaning, suspended overhead magnet was used to separate rebar from crushed concrete inside a concrete recycling system.

Category | Bulk Bag Unloaders | Valve Bag Fillers |

This system unloads and transfers fine powder from a bulk bag and conveys it to a valve bagging machine for down packing, or repackaging

Category | Automatic Bagging Machines | Bag Handling Conveyors | Valve Bag Fillers |

Auger fillers convey golf course sand into 50 lb. valve bags at a rate of 1-5 bags per minute. They simultaneously fill and weigh the sand directly into the bags.

These types of valve bag filling machines are also used to fill bags with other types of powdery or small granular materials such as:

Category | Bulk Bag Unloaders | Valve Bag Fillers |

This material transfer system conveys the contents of a bulk bag into 10 to 100 pound valve bags. It can be used to transfer materials such as powders or small granules including finish cement, bentonite, barite, fertilizers, frac sand, powdered limestone, gypsum, powdered iron ore, oil drilling chemical powders, titanium dioxide, and more.