« Equipment and Systems

-

- Open Mouth Baggers

- Valve Bag Filling Machines

- Bulk Bag Filling Machines

- Bulk Bag Unloaders

- Bag Sewing Machines

- Bag Sealing Equipment

- Bag Handling Conveyors

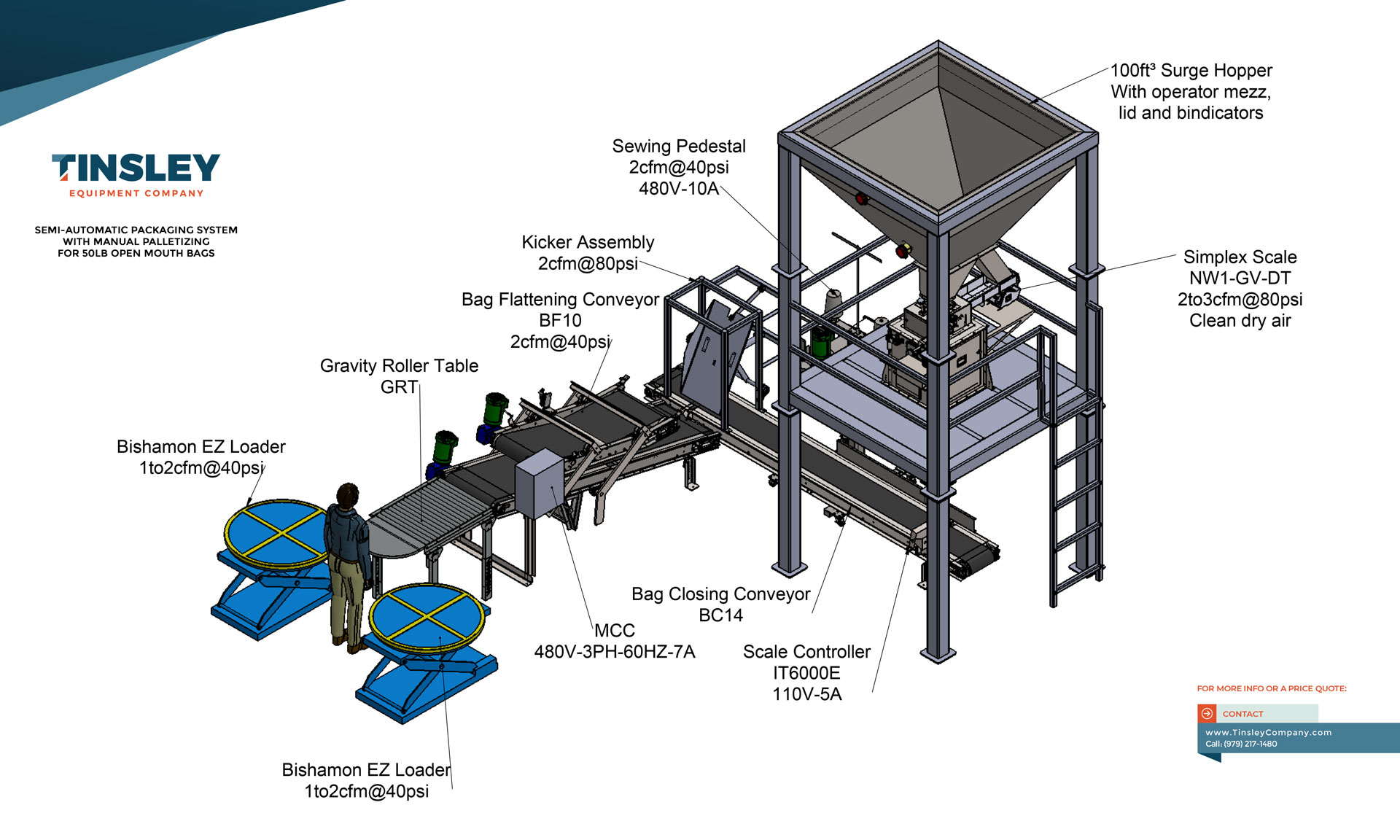

- Manual Palletizing Systems

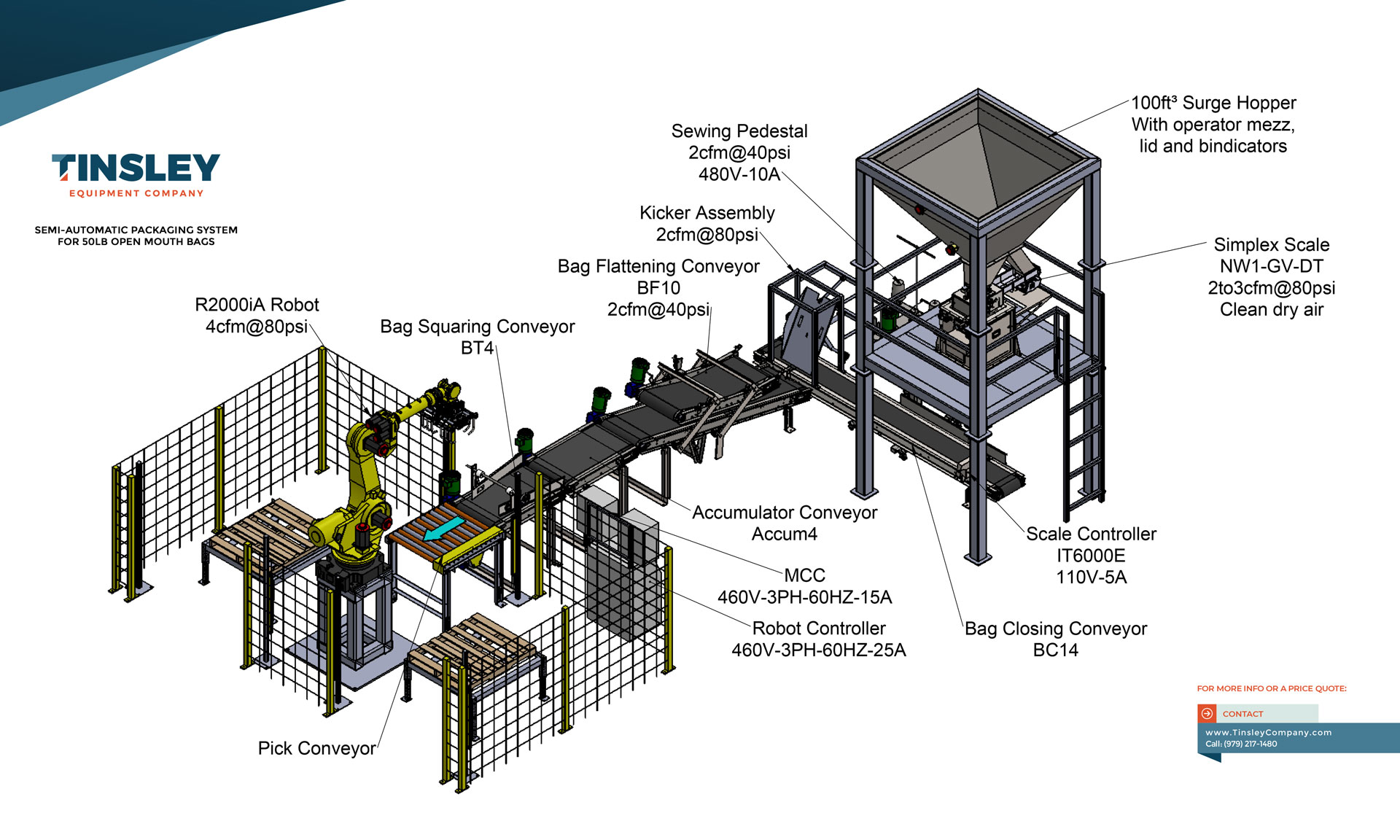

- Robotic Bag Palletizers

- Gantry Palletizer Systems

- Automated Pallet Wrappers

- Automatic Bagging

Machines & Systems - IBC Blending

- Stainless Steel Intermediate Bulk Containers

Open Mouth Baggers and Bagging Scales

Fill, weigh, and seal open mouth bags with powders, pellets, flakes, granules, and fibrous materials with manual to automatic baggers and bagging scales.

Open mouth baggers have a larger spout to fill open mouth style bags, burlap sacks, pails, boxes, totes, and more. These machines typically fill bags to weights of 20-110 pounds (9-50 kilograms) using mechanical or digital bagging scales at rates up to 24 bags per minute (1,440 bags per hour). Smaller baggers typically fill bags and pouches to weights of 1-25 pounds using digital net weigh scales at rates up to 30+ bags per minute or (1,800 bags per hour). They are used in many different types of industries including aggregate, stone, minerals, agriculture, animal feed, pet food, seed, cement, concrete, chemical, fertilizer, food, ingredients, nuts, landscaping products, and more.

Gross weigh baggers weigh the material in the bag as it is being filled. Net weigh baggers pre-weigh the material in an internal hopper and then dump it into a bag. Filling bags using a net weigher is about 2 times faster because the operator can position a bag on the spout as the internal hopper is being filled above.

Click a link below to jump to a section on this page:

- Small Net Weigh Bagging Scales (30+ Bags or Pouches/Min)

- Mechanical Gross Weigh Bagging Scales (4 Bags/Min)

- Digital Gross Weigh Bagging Scales (4 Bags/Min)

- Digital Gross Weigh Bagging Scales with Pneumatic Bag Clamp (7 Bags/Min)

- High-Speed Net Weigh Bagging Machines (24 Bags/Min)

Available Models

Small Net Weigh Bagging Scales

This type of small open mouth bagger quickly fills bags and pouches with 1-25 lbs. of dry, free-flowing products. The standard small net weigh bagging scale includes a gravity gate, single vibrating pan feeder, and a weigh hopper that is suspended from a single load cell. It is available in simplex, duplex, and triplex configurations for high speed commercial packaging systems.

Add a 4 inch diameter auger feeder for fluid products or interface with vertical or horizontal form, fill, and seal machines. Stainless steel product contact surfaces or food-grade stainless steel construction is available, as well as dust tight spouts and enclosures.

Simplex scale configuration: Up to 12 bags per minute (720 bags per hour)

Duplex scale configuration: 20+ bags per minute (1,200 bags per hour)

Triplex scale configuration: 30+ bags per minute (1,800 bags per hour)

Accuracy: +/- 0.5-1% of target weight

Bag weight range: 1-25 pound bags (0.45-2.26 kilograms)

Bag types: pre-formed open mouth bags, stand up pouches, or doypacks constructed of paper, plastic, or poly-woven materials

- aquarium gravel and specialty aggregates

- almonds

- bird seed

- cashews

- cat food

- chia seeds

- chicken grit

- coffee beans

- cover crop seeds

- dog food

- dried fruits

- grains

- grass seed

- ground coffee

- hop pellets

- peanuts

- plastic pellets

- small feed pellets

and poultry feed - rice

- seeds

- sugar

- sunflower seeds

- test plot seeds

- water filtration products

- wood pellets

- and more

Compressed air required

Electrical: 1 or 3 phase

Dust Collection: optional

Images

Click or tap a thumbnail below to view a larger image.

Watch a Video:

Need help fast? Use our Express Contact Form

Call: (979) 217-1480

Mechanical Gross Weigh Bagging Scales

No air or electricity is required for basic operation. This type of manual open mouth bagger packages granular, free-flowing, and non-dusty products into open mouth bags (50 lb grain bags being the most popular). Product flows by gravity from a supply hopper into the bagger. When a fill cycle is initiated, product flows through the gravity gate into a funnel spout and into the bag. This type of machine is an automatic mechanical gross weigh scale that simultaneously fills and weighs product directly into the bag. This bagger is available with a 22 or 29 inch spout circumference and is the perfect entry-level bag filling machine.

Fill rate: 4 bags per minute or 200 bags per hour

Accuracy: +/- 0.5-1% of target weight

Bag weight range: 20-110 pound bags (9-50 kilograms)

Bag types: paper and poly-woven open mouth bags

- Deer Corn

- Whole Corn

- Cracked Corn

- High Moisture Corn

- Grains

- Seeds

- Nuts

- Flour

- Rice

- Soybeans

- Animal Feed

- Bird Seed

- Sugar

- Salt

- Fertilizer

- Ice Melting Salt

- PVC Resin

- Plastic Pellets

- Wood Pellets

- Activated Carbon

- Pea Gravel

- Dry Sand

- Aggregate

(3/4" down to coarse sand)

Control Air: none required

Electrical: none required

Dust Collection: none required

Images

Click or tap a thumbnail below to view a larger image.

Videos

Need help fast? Use our Express Contact Form

Call: (979) 217-1480

Digital Gross Weigh Bagging Scales

This type of open mouth bagging machine packages granular, free-flowing, and non-dusty products into open mouth bags. Product flows by gravity from a supply hopper into the machine. When a fill cycle is initiated, product flows through the digitally controlled gravity gate into a funnel spout and into the bag. This type of bagging machine is an automatic gross weigh scale that simultaneously fills and weighs product directly into the bag. This bagger has an easy fill weight set up with auto tare. This bagging machine is available with a 22 or 29 inch spout circumference and is the perfect entry-level bagger.

Fill rate: 4 bags per minute or 200 bags per hour

Accuracy: +/- 0.5-1% of target weight

Bag weight range: 20-110 pound bags (9-50 kilograms)

Bag types: paper and poly-woven open mouth bags

- Deer Corn

- Whole Corn

- Cracked Corn

- High Moisture Corn

- Grains

- Seeds

- Nuts

- Flour

- Rice

- Soybeans

- Animal Feed

- Bird Seed

- Sugar

- Salt

- Fertilizer

- Ice Melting Salt

- PVC Resin

- Plastic Pellets

- Wood Pellets

- Activated Carbon

- Pea Gravel

- Dry Sand

- Aggregate

(3/4" down to coarse sand)

Control Air: 80 PSI required at 1 CFM per bag fill cycle

Electrical: 110 or 220 volt / 1 phase / 60 cycle

Dust Collection: none required

Images

Click or tap a thumbnail below to view a larger image.

Watch a Demonstration Video:

Need help fast? Use our Express Contact Form

Call: (979) 217-1480

Digital Gross Weigh Bagging Scales with a Pneumatic Bag Clamp

This type of open mouth bagger packages granular, free-flowing, and non-dusty products into open mouth bags. Product flows by gravity from a supply hopper into the machine. When a fill cycle is initiated, product flows through the gravity gate into a funnel spout and into the bag. This type of machine is an automatic digital scale gross weighing filler that simultaneously fills and weighs product directly into the bag. This bagging machine has advanced digital control with a pneumatic bag clamp that is activated by foot pedal. It is available with a 21, 25, or 31 inch spout circumference.

Fill rate: 6-7 bags per minute or 300 bags per hour

Accuracy: +/- 0.5-1% of target weight

Bag weight range: 20-110 pound bags (9-50 kilograms)

Bag types: paper, plastic, and poly-woven open mouth bags

- Deer Corn

- Whole Corn

- Cracked Corn

- High Moisture Corn

- Grains

- Seeds

- Flour

- Rice

- Soybeans

- Barley

- Animal Feed

- Bird Seed

- Sugar

- Salt

- Fertilizer

- Ice Melting Salt

- PVC Resin

- Plastic Pellets

- Wood Pellets

- Activated Carbon

- Pea Gravel

- Dry Sand

- Aggregate

(3/4" down to coarse sand)

Control air: 80 PSI required at 1 CFM per bag fill cycle

Electrical: 110 or 220 volt / 1 phase / 60 cycle, 440 volt / 3 phase / 60 cycle

Dust collection: 400 CFM minimum

Images

Click or tap a thumbnail below to view a larger image.

Videos

Need help fast? Use our Express Contact Form

Call: (979) 217-1480

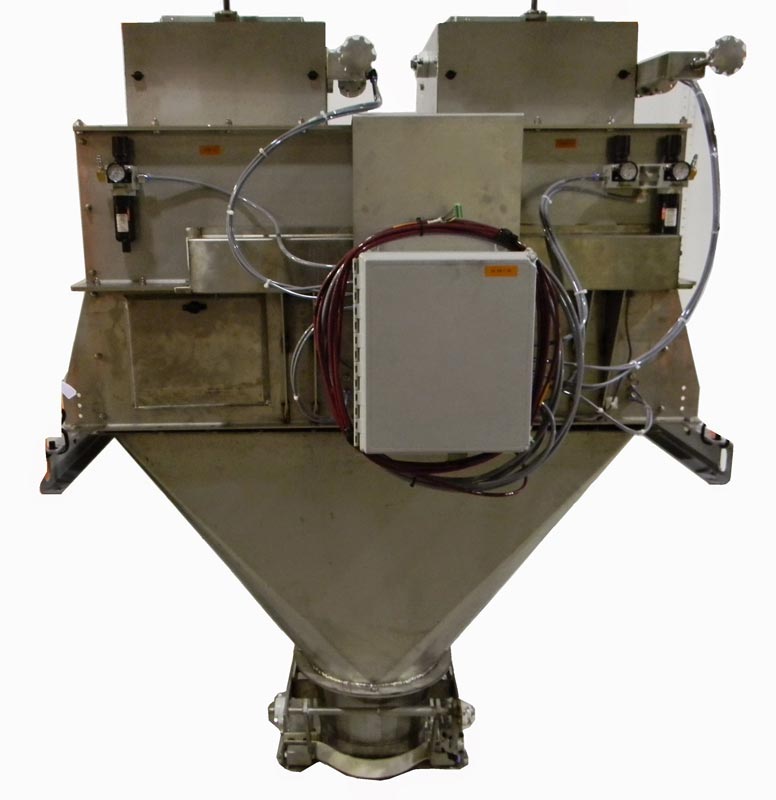

High-Speed Net Weigh Bagging Machines

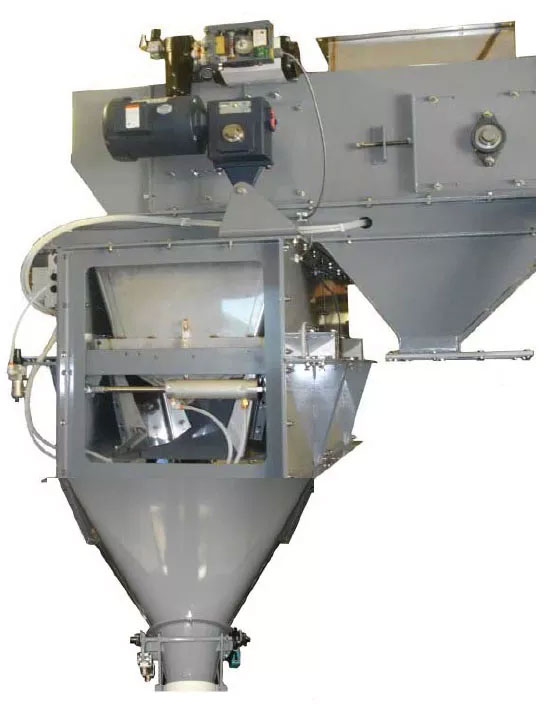

These types of open mouth baggers package granular (80 mesh or coarser), free-flowing, and non-dusty products into open mouth bags, boxes, pails, and drums. Product flows by gravity from a supply hopper into the bagging machine. The machine automatically loads product into an internal weigh hopper without operator assistance. When a fill cycle starts, the product is discharged from the internal weigh hopper, through a funnel spout, and into the bag. At the same time as material discharge, the machine loads product into the internal weigh hopper for the next fill cycle. This type of machine is an automatic net weigh filler that pre-weighs material before discharging into a bag or container. It is considered the open mouth bagger of choice for high volume or industrial bagging operations that bag animal feed, aggregate, corn, nuts, and more.

Fill rate: Up to 24 bags per minute

Accuracy: +/- 0.5-1% of target weight

Bag weight range: 20-110 pound bags (9-50 kilograms)

Bag types: paper, plastic, and poly-woven open mouth bags

- Deer Corn

- Grains

- Seeds

- Almonds

- Flour

- Rice

- Soybeans

- Barley

- Animal Feed

and Cubes - Molasses Feed

- Bird Seed

- Fish Feed

- Sugar

- Salt

- Cake Mixes

- Spices

- Nuts

- Milk Powder

- Fertilizer

- Ice Melting Salt

- PVC Resin

- Plastic Pellets

- Dry and Damp Sand

- Aggregate (3/4" down to coarse sand - Add belt or vibratory feeder for larger aggregate)

Control air: 80 PSI required at 1 CFM per bag fill cycle

Electrical: 220 volt, 380 volt, 440 volt, or 575 volt / 3 phase / 60 cycle

Dust collection: 600 CFM minimum

Images

Click or tap a thumbnail below to view a larger image.

Videos

Need help fast? Use our Express Contact Form

Call: (979) 217-1480

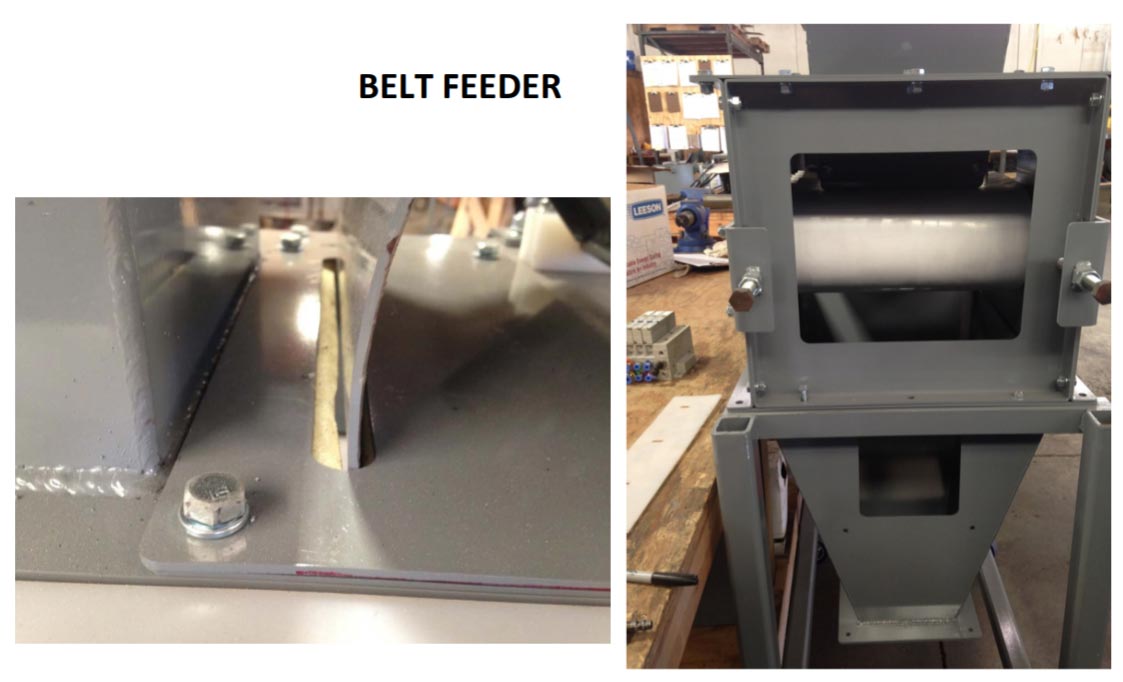

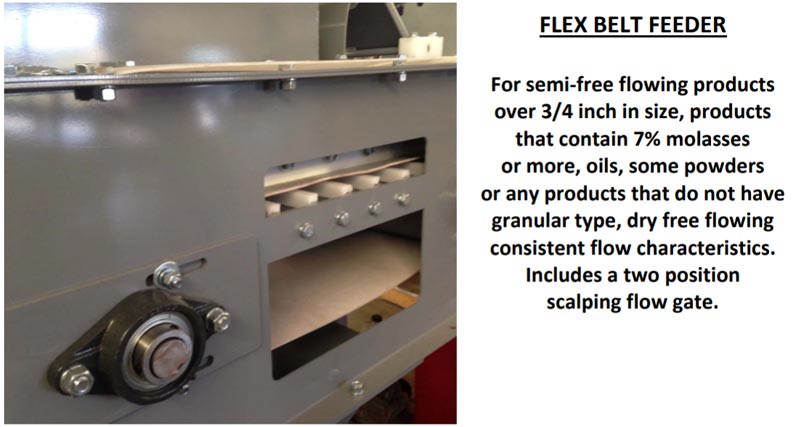

Belt Fed Bagging Machines

This type of open mouth bagger packages non-free flowing powders, granules, and flaky materials into open mouth bags (eg. sticky animal feeds with molasses). Product flows by gravity from a supply hopper into the machine. When a fill cycle starts, the product is conveyed through a specially designed belt feeder that conditions and delivers it in an even and consistent flow to the bagging scale. The product is simultaneously filled and weighed into the bag. When the target weight has been reached, the belt feeder will stop, and the cutoff gate in the machine closes. The air operated bag clamp automatically releases the bag from the scale. For difficult to handle materials, the gravity gate is removed completely.

Fill rate: 1-8 bags per minute

Accuracy: +/- 0.5-1% of target weight

Bag weight range: 20-110 pound bags (9-50 kilograms)

Bag types: paper, plastic, and poly-woven open mouth bags

- Animal Feed

with Sticky Molasses - Cattle Cubes

- Range Cubes

- Hay Cubes

- Fish Feed

- Milk Powder

- Cake Mixes

- Brown Sugar

- Damp Sand

- Gravel

- Soil

Control air: 80 PSI required at 1 CFM per bag fill cycle

Electrical: 220 volt, 380 volt, 440 volt or 575 volt / 3 phase / 60 cycle

Dust collection: 600 CFM minimum

Need help fast? Use our Express Contact Form

Call: (979) 217-1480

Vibratory Fed Bag Filling Machine

This type of bag filling machine packages free-flowing granular products and pellets into bags. Product flows by gravity from a supply hopper into the machine. When a fill cycle starts, the product flow is divided into two flows. One feeds to a gravity style swing gate for a faster bulk flow. The other flow goes to a vibratory pan feeder for a slower dribble type flow. As the bag approaches the target weight, the gravity gate closes, and the vibratory feeder will continue feeding material until the target weight is reached. An air-operated bag clamp secures the bag to the machine during filling and automatically releases once the target weight is reached. This type of machine is an automatic gross weigh filler that simultaneously fills and weighs product directly into the bag.

Fill rate: 1-10 bags per minute

Accuracy: +/- 0.5-1% of target weight

Bag weight range: 20-110 pound bags (9-50 kilograms)

Bag types:paper, plastic, and poly-woven open mouth bags

- Grains

- Seeds

- Flour

- Rice

- Soybeans

- Animal Feed

- Bird Seed

- Wood Pellets

- Activated Carbon

- Pea Gravel

- Sugar

- Salt

- Cake Mixes

- Spices

- Milk Powder

- Fertilizer

- Ice Melting Salt

- PVC Resin

- Plastic Pellets

- Dry Sand

Control air: 80 PSI required at 1 CFM per bag fill cycle

Electrical: 110 volt / 1 phase / 60 cycle

Dust collection: 400 CFM minimum

Need help fast? Use our Express Contact Form

Call: (979) 217-1480

Auger Fed Bag Filling Machines

This type of bag filling machine packages free-flowing, non-free flowing and floodable powders into open mouth bags. Product flows by gravity from a supply hopper into the machine. When a fill cycle is initiated, product is fed using an auger feeder into the funnel spout and into the bag. This type of machine is an automatic digital scale gross weighing filler that simultaneously fills and weighs product directly into the bag.

Fill rate: 1-5 bags per minute

Accuracy: +/- 0.5-1% of target weight

Bag weight range: 20-110 pound bags (9-50 kilograms)

Bag types: paper, plastic, and poly-woven open mouth bags

- Powders

- Flour

- Cake Mixes

- Spices

- Milk Powder

- Chemical Powders

- Pigments

Control air: 80 PSI required at 1 CFM per bag fill cycle

Electrical: 220 volt, 380 volt, 440 volt or 575 volt / 3 phase / 60 cycle

Dust collection: 400 CFM minimum

Images

Click or tap a thumbnail below to view a larger image.

Need help fast? Use our Express Contact Form

Call: (979) 217-1480

Auger Fed Gross Weigh Bag Filling Machines

This type of bag filling machine packages free-flowing and floodable powders into bags. Product flows by gravity from a supply hopper into the machine. When a fill cycle starts, the product is conveyed through a specially designed auger feeder that conditions and delivers it in an even and consistent flow to the weighing scale. The product is simultaneously filled and weighed into the bag. When the target weight has been reached, the auger feeder will stop and the cutoff gate in the machine closes. The air operated bag clamps automatically release the bag from the scale.

Fill rate: 1-10 bags per minute

Accuracy: +/- 0.5-1% of target weight

Bag weight range: 20-110 pound bags (9-25 kilograms)

Bag types: paper, plastic, and poly-woven open mouth bags

- Flour

- Cake Mixes

- Spices

- Milk Powder

- Chemical Powders

- Pigments

Control air: 80 PSI required at 1 CFM per bag fill cycle

Electrical: 220 volt, 380 volt, 440 volt or 575 volt / 3 phase / 60 cycle

Dust collection: 400 CFM minimum

Need help fast? Use our Express Contact Form

Call: (979) 217-1480