« Equipment and Systems

-

- Open Mouth Baggers

- Valve Bag Filling Machines

- Bulk Bag Filling Machines

- Bulk Bag Unloaders

- Bag Sewing Machines

- Bag Sealing Equipment

- Bag Handling Conveyors

- Manual Palletizing Systems

- Robotic Bag Palletizers

- Gantry Palletizer Systems

- Automated Pallet Wrappers

- Automatic Bagging

Machines & Systems - IBC Blending

- Stainless Steel Intermediate Bulk Containers

Automated Pallet Wrappers

Automate the tedious job of applying stretch wrap to pallet loads.

These automated pallet wrappers, or stretch wrappers, are used for wrapping shipping pallets containing bags, boxes, pails, and more. They can be stand-alone automatic or semi-automatic stretch wrap machines. They can also be fully automatic wrapping machines that are integrated into conveyors on a bagging line.

Each type of pallet wrapping machine can be pre-programmed with separate wrap patterns and speeds for different types of loads. Once programmed and set, all it takes is a simple push of a button to start the automated wrapping process.

- Turntable stretch wrap machines turn or rotate the pallet load as it is wrapped. These types of machines are used for wrapping 35-45 pallets an hour or less. Low profile turntables are best for use with pallet jacks, while high profile stretch wrappers are used when loading with a forklift.

- Rotary arm stretch wrap machines are used when you want to keep a pallet load stationary. They can wrap up to 35-95 pallets per hour. These types of loads wrapped by a rotary arm could include tall pallet loads, very heavy or very light loads, or unstable pallet loads. They are also used in bagging or packaging lines that require washdown environments because there are no drives or parts at floor level.

Available Models

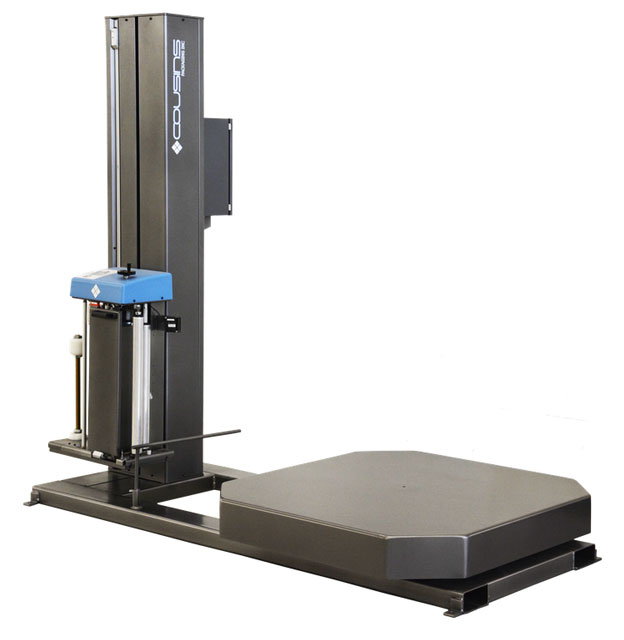

Turntable, Semi-Automatic Stretch Wrap Machines (Fork Lift or Pallet Jack Loaded)

These types of stand-alone, automated pallet wrappers are some of the most popular and affordable machines on the market today. Choose from low profile and high profile semi-automatic stretch wrap machines that average up to 35 loads per hour per single turntable.

Once a pallet is ready to be wrapped, an operator will transport it to the turntable using a pallet jack or forklift. Then, with a simple push of a button, the machine will rotate the turntable as wrap is applied using an automated film carriage. A set amount of plastic stretch wrap is applied with a consistent stretch, thus reducing plastic wrap costs.

- Wrap approximately 35 loads per hour

- 4,000 lb. rotating load capacity

- Load sizes:

- Low profile: 50” x 50” (71” diagonal) x 82” H

- High profile: 56” x 56” (79” diagonal) x 75” H

- Turntable sizes:

- Low profile: 57″ diameter turntable, 2.75" from floor

- High profile: 48″ octagonal 5/16″ thick turntable, 11” from floor

Additional Standard Features

- Optional tower extension extends wrap height to 110”

- NEMA 12 control panel with simple LCD operator interface including helpful diagnostics and emergency stop

- Carriage cable wires not exposed on tower design

- Automatic pre-stretch film carriage uses less stretch wrap and has built in obstruction auto stop

- Automatic power shut off when stretch wrap film replacement

- Less stretch wrap slippage means more consistent stretch and the “sticky” side of the wrap will always be against both the rubber rollers and the pallet load where it belongs

- All AC motors and gearboxes are fully enclosed and guarded

- Load with a manual pallet jack, powered pallet jack, or forklift

- Lifting tubes are located on the front and rear of the stretch wrap machine for easy portability

- Built in North America with brand name components

Optional Features:

- Ramp for manual pallet jack loading

- Porch extensions for powered pallet jacks

- Built-in load cells scale package to wrap and weigh at the same time

- Tower extensions for up to 110” wrap height

- 2 ft. base extension for maximum 119” diagonal (71” and 79” diagonals are standard)

- Automatic stretch wrap cutter

- Automatic stretch wrap start using a wireless remote and film attachment clip on the turntable to start a wrap cycle

- Fully automatic upgrade with the addition of an A-arm

- Dusty environment package with complete sealing of control panel and conduit entries

- Cold weather package down to 33°F

- Freezer package 32°F to -20°F

- Dual turntables – add a second turntable to increase production rates

- Air flow film splitter for pallet loads that need to breathe or require more holding force

Need help fast? Use our Express Contact Form

Call: (979) 217-1480

Turntable, Fully Automatic Stretch Wrap Machines (Fork Lift or Pallet Jack Loaded)

These types of automated pallet wrappers use an A-arm to attach and cut the plastic stretch wrap. These machines are operated using a wireless remote. This eliminates the need for an operator to leave the forklift to cut the plastic stretch wrap, thus providing labor cost savings while eliminating some safety concerns.

Once a pallet is ready to be wrapped, an operator will transport it to the turntable using a forklift or pallet jack. Then, with a simple push of a button on the remote, the machine will rotate the turntable as wrap is applied using an automated film carriage. A set amount of plastic stretch wrap is applied with a consistent stretch, thus reducing plastic wrap costs.

- Controlled wireless via remote or manually via control panel

- Wrap approximately 35 loads per hour

- 4,000 lb. rotating load capacity

- Load sizes:

- Low profile: 64” x 64” (90” diagonal) x 80” H

- High profile: 64” x 64” (90” diagonal) x 75” H

- Turntable sizes:

- Low profile: 65″ diameter turntable, 2.75" from floor

- High profile: 48″ octagonal 5/16″ thick turntable, 11” from floor

- All-Electric – No Pneumatics Required

- Control panel with simple LCD operator interface including helpful diagnostics for automatic / semi-automatic / top banding modes (3 year warranty on control components)

Additional Standard Features:

- Carriage cable wires not exposed on tower design (5 year warranty on steel fabrications)

- Super Rapid Thread II powered pre-stretch film carriage uses less film (Lifetime warranty on pre-stretch rollers)

- Less film slippage means more consistent stretch and the “sticky” side of the film will always be against both the rubber rollers and the load where it belongs

- All motors/gearboxes fully enclosed & guarded

- All AC motors

- 4500# load capacity with heavy-duty surround deck

- Lifting tubes – front and rear for easy portability.

- Built in North America with brand name components

Optional Features:

- Ramp for manual pallet jack loading - 48”W x 60”L

- Porch extensions are available for powered pallet jacks

- Built-in load cells scale package to wrap and weigh at the same time

- Tower extensions for up to 110” wrap height

- 2 ft. base extension for maximum 119” diagonal (71” diagonal is standard)

- Automatic stretch wrap cutter

- Automatic stretch wrap start using a wireless remote and film attachment clip on the turntable to start a wrap cycle

- Pallet lock roping device

- Fully automatic upgrade with the addition of an A-arm

- Dusty environment package with complete sealing of control panel and conduit entries

- Cold weather package down to 33°F

- Freezer package 32°F to -20°F

- Dual turntables – add a second turntable to increase production rates

- Air flow film splitter for pallet loads that need to breathe or require more holding force

Need help fast? Use our Express Contact Form

Call: (979) 217-1480

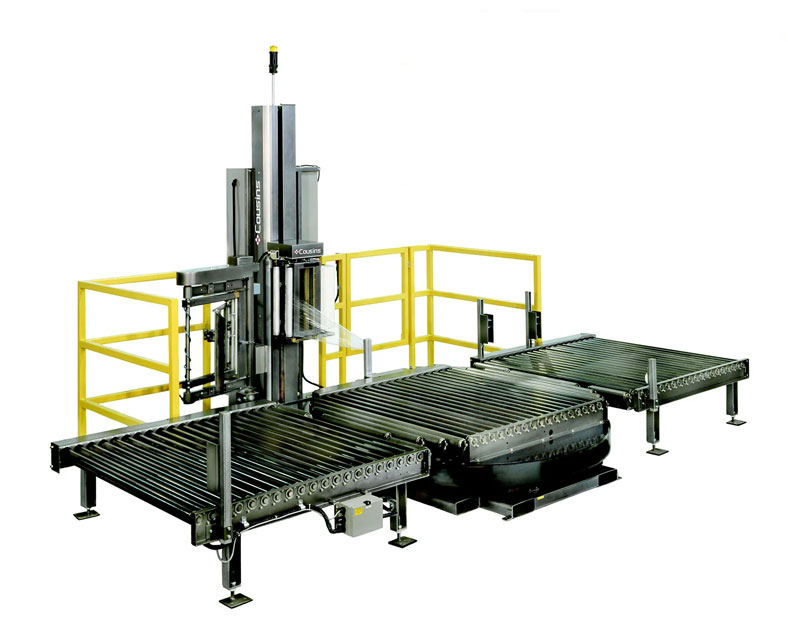

Turntable on a Conveyor, Fully Automatic Stretch Wrap Machines

These types of automated pallet wrappers can be stand-alone or as a part of a fully automatic conveyorized system. The basic system can hold 2 pallets, with the ability to add more pallet conveyors as necessary. A wireless remote starts the stand-alone system, whereas the in-line system automatically starts using interface relays / logic connected to the conveyor system.

There is a model that uses an A-arm to automatically attach and cut the plastic stretch wrap. The other models use a clamp, cut, and wipe assembly with a film carriage mounted to the tower.

- Stand-Alone System: Controlled wireless via remote or manually via control panel

- In-Line System: Controlled using interface relays and logic

- Wrap approximately 35-45 loads per hour

- 4,000 lb. rotating load capacity

- Load sizes:

- 48″ W x 48″ L (68″ max. load diagonal) x 70″ H (plus up to 2″ top overlap)

- 48″ W x 48″ L (68″ max. load diagonal) x 75″ H (plus up to 2″ top overlap)

- 50″ W x 50″ L (71″ max. load diagonal) x 82″ H (plus up to 4″ top overlap)

- Turntable sizes:

- 72″ diameter turntable

- 80″ diameter skirted turntable

- Conveyors for A-Arm Model:

- 5” diameter rollers on 3” centers

- 50” effective roller width

- 5” standard pass line height

- AC drives

- Conveyors for In-line or Higher Speeds:

- 5” diameter rollers on 3” centers

- 54” effective roller width

- 18” pass line height

- Soft start VAC controls and automatic load staging photo-eyes

Additional Standard Features

- Super Rapid Thread II powered pre-stretch film carriage uses less film

- Less film slippage means more consistent stretch and the “sticky” side of the film will always be against both the rubber rollers and the load where it belongs

- NEMA 12 control panel with simple LCD operator interface including helpful diagnostics and emergency stop

- PANASONIC FP-X Programmable Logic Controller (PLC)

- All motors/gearboxes fully enclosed and guarded

- Built in North America with brand name components

Optional Features:

- Additional powered infeed and outfeed sections including 90° transfers

- Frame extensions for larger load sizes

- Lifting device to wrap under pallet

- Scales

- Tapered end-stop and full photo-eye / logic

- Tower extension for added height capability

- Allen-Bradley MicroLogix 1400 PLCs

- Non-standard voltage kits

- Non-standard PLC / Controls

- Safety fence packages

- Pallet lock roping device

Need help fast? Use our Express Contact Form

Call: (979) 217-1480

Rotary Arm, Semi-Automatic Stretch Wrap Machines (Fork Lift or Pallet Jack Loaded)

These types of automated pallet wrappers use an arm that moves around a pallet load that rests on the floor. This type of stationary pallet wrapping machine can be wall mounted or post mounted to the floor. They are used to wrap tall, heavy, very light, or unstable loads.

Once a pallet is ready to be wrapped, an operator will transport it to the rotary arm wrapper using a forklift or pallet jack and place it on the floor. Then, with a simple push of a button on the control panel, the machine’s arm will swivel and move around the stationary pallet load as wrap is applied using an automated film carriage. A set amount of plastic stretch wrap is applied with a consistent stretch, thus reducing plastic wrap costs.

- Controlled manually via control panel with single button auto wrap cycle start / pause

- Wrap approximately 30-40 loads per hour

- Choose a frame that fits your product line: Rear Mount, Post Mount, 3 Post Stand, 4 Post Stand

- Unlimited load capacity (floor supported)

- Load sizes:

- Free-standing Rear Mount / Post Mount / Wall Mount: 50” x 50” (71” diagonal) x 86” H

- Heavy-duty Four Post Frame: 56″ x 56″ (79″ diagonal) x 80″ H (plus up to 4″ top overlap)

Additional Standard Features

- NEMA 12 control panel with simple LCD operator interface including helpful diagnostics for automatic / semi-automatic / top banding modes (3 year warranty on control components)

- Arm / Tower design: all structural steel construction with double flange bearing support system and 1-12 RPM rotational speed c/w soft start acceleration, rotary arm obstruction emergency safety stop sensor

- Triple beam type auto load height sensing photo-eye, detects dark or shiny loads

- Super Rapid Thread II powered pre-stretch film carriage uses less film

- Fixed stretch capacity ranges from 33 to 313 percent

- Pre-stretch rollers come with a lifetime warranty

Optional Features:

- 48" W x 48" L x 4" H pallet platform - decreases maximum wrap height by 4"

- Side Safety Fences and Front Sliding Gate

- Frame height extension for 110” tall loads (86” is standard) – other extensions are available

- Frame extension for maximum 86” diagonal (71” is standard) – other extensions are available

- Broken film / out of film detection

- 30” plastic wrap film carriage – accommodates standard 20” and 30” wide rolls of plastic wrap

- AC variable speed drives in place of standard DC

- Cold weather package down to 33°F

- Freezer package 32°F to -20°F

- Platform scales with digital weight indicators

Need help fast? Use our Express Contact Form

Call: (979) 217-1480

Rotary Arm, Fully Automatic Stretch Wrap Machines

These types of automated pallet wrappers have more automation built in such as a pneumatic actuated film clamp mechanism (all electric is optional), electro-mechanically actuated film tail cut or wiper mechanism, and impulse hot wire film cut off come with automatic periodic cleaning cycle.

They have an arm that moves around a pallet load that rests on the floor. This type of automatic stationary pallet wrapping machine can be wall mounted or post mounted to the floor. They are used to wrap oversized and heavy loads.

Once a pallet is ready to be wrapped, an operator will transport it to the rotary arm wrapper using a forklift or pallet jack. Then, with a simple push of a button on the control panel or on the wireless remote, the machine’s arm will swivel and move around the stationary pallet load as wrap is applied using an automated film carriage. A set amount of plastic stretch wrap is applied with a consistent stretch, thus reducing plastic wrap costs.

- Controlled manually via control panel with single button auto wrap cycle start / pause or wireless start/stop transmitter and receiver for remote operator control – optional lanyard, pedestal or pendant control station available

- Wrap approximately 30-40 loads per hour

- Choose a frame that fits your product line: Rear Mount, Post Mount, 3 Post Stand, 4 Post Stand

- Unlimited load capacity (floor supported)

- Load sizes:

- Free-standing Rear Mount / Post Mount / Wall Mount: 50” x 50” (71” diagonal) x 86” H

- Heavy-duty Four Post Frame: 56" x 56" (79" diagonal) x 80" H (plus up to 4" top overlap)

Additional Standard Features

- NEMA 12 control panel with simple LCD operator interface including helpful diagnostics for automatic / semi-automatic / top banding modes (3 year warranty on control components)

- Arm / Tower design: all structural steel construction with double flange bearing support system and 1-12 RPM rotational speed c/w soft start acceleration, rotary arm obstruction emergency safety stop sensor

- Triple beam type auto load height sensing photo-eye, detects dark or shiny loads

- Super Rapid Thread II powered pre-stretch film carriage uses less film

- Fixed stretch capacity ranges from 33 to 313 percent

- Pre-stretch rollers come with a lifetime warranty

Optional Features:

- 48" W x 48" L x 4" H pallet platform - decreases maximum wrap height by 4"

- Side Safety Fences and Front Sliding Gate

- Frame height extension for 110” tall loads (86” is standard) – other extensions are available

- Frame extension for maximum 86” diagonal (71” is standard) – other extensions are available

- Broken film / out of film detection

- 30” plastic wrap film carriage – accommodates standard 20” and 30” wide rolls of plastic wrap

- AC variable speed drives in place of standard DC

- Platform scales with digital weight indicators

- Cold weather package down to 33°F

- Freezer package 32°F to -20°F

Need help fast? Use our Express Contact Form

Call: (979) 217-1480

Rotary Arm Over a Conveyor, Fully Automatic Stretch Wrap Machines

These types of automated pallet wrappers are built for production line applications. Pallet loads are conveyed automatically to the wrap zone where a rotary arm moves around it, dispensing plastic stretch wrap.

They can wrap between 45-95 loads per hour depending on the type of automated bagging system or production line. A built-in, simple conveyor system lets you customize the wrapping solution for your system.

- Wrap approximately 45-95 loads per hour

- 4,000 Lb. load capacity

- Load sizes:

- Basic system: 50” x 50” (71” diagonal) x 80” H

- Heavy-duty system: 52″ x 52″ (79" diagonal) x 80" H (plus up to 4" top overlap)

- NEMA 12 control panel with simple LCD operator interface including helpful diagnostics for automatic / semi-automatic / top banding modes

- Basic system includes the following 54” power roller conveyors:

- 5ft Infeed conveyor

- 11ft Wrap zone conveyor

- 5ft Exit conveyor

Additional Standard Features

- Super Rapid Thread II powered pre-stretch film carriage uses less film

- Pneumatically actuated film clamp mechanism and film tail cut or wiper arm mechanism

- Ni-chrome impulse hot wire film cut off comes with automatic periodic cleaning cycle

- PANASONIC FP-X Programmable Logic Controller (PLC)

Optional Features:

- Additional powered infeed and outfeed sections including 90° transfers

- Frame extensions for larger load sizes

- Lifting device to wrap under pallet

- Scales

- Allen-Bradley MicroLogix 1400 PLCs

- Non-standard voltage kits

- Non-standard PLC / Controls

- Safety fence packages

Need help fast? Use our Express Contact Form

Call: (979) 217-1480