« Equipment and Systems

-

- Open Mouth Baggers

- Valve Bag Filling Machines

- Bulk Bag Filling Machines

- Bulk Bag Unloaders

- Bag Sewing Machines

- Bag Sealing Equipment

- Bag Handling Conveyors

- Manual Palletizing Systems

- Robotic Bag Palletizers

- Gantry Palletizer Systems

- Automated Pallet Wrappers

- Automatic Bagging

Machines & Systems - IBC Blending

- Stainless Steel Intermediate Bulk Containers

Stainless Steel IBC Containers with Built-In Cone Valves

food grade, and easy-to-clean. Multiple sizes are available.

Process, store, transport, and feed powders and dry bulk solids using stainless steel IBC containers with a conical bottom.

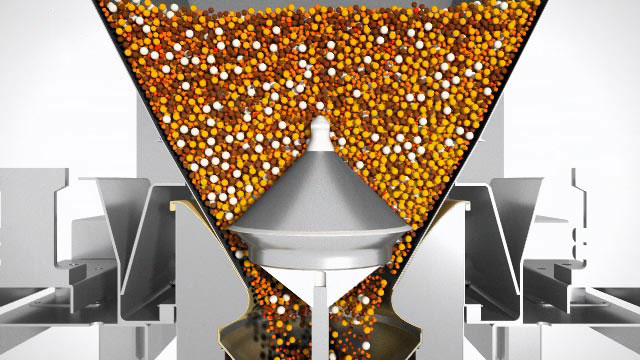

These intermediate bulk containers, or IBCs, have a conical bottom discharge design. They use an integrated cone valve to discharge or feed powders, granules, tablets, pellets, seasonings, pharmaceuticals, drink mixes, and more into downstream IBC blending systems, bagging machines, feeders, and bulk process systems without rat holing, bridging, blocking, or blend segregation.

These intermediate bulk containers with conical bottoms are designed to be used in a bulk handling system.

- Use them as a refill bin, or as part of a refill system for volumetric loss-in-weight feeders. These IBC containers are easily transported and mounted onto a discharge system located above a feeder and can slowly discharge powders into the feeder’s hopper.

- Uniformly blend, mix, and formulate dry ingredients inside of a stainless steel intermediate bulk container using a tumbling blender. Then, transport the IBC to a discharge system to feed bagging machines with the blended product while maintaining a consistent blend, sanitary requirements, and dust containment.

- Reduce process downtime by easily disassembling and cleaning the parts of the food grade stainless steel IBC containers and discharge system. Use a wash-down or blown-down process for fast reuse to re-mix another recipe or to build a completely new recipe inside the IBC.

- Easily expand your production or packaging line as your business grows. All intermediate bulk containers, parts, equipment, and systems are sold and delivered direct from the United States!

Features

- Stainless steel IBC container volumes range from 500 - 3,000 liters (appx. 18 - 106 cubic feet)

- Square width and depth measuring appx. 46”x46” (1160mm x 1160mm) with heights ranging from appx. 44” up to 121” (1127mm x 3081mm)

- IBC containers are manufactured in 304 stainless steel and 316L stainless steel.

- These intermediate bulk containers include a cone valve to promote uniform discharge of blended materials like powders.

- Use these IBCs with a discharge system for automatic connection without manual intervention.

- These IBCs are stackable and can be moved using a forklift saving valuable floor space.

- Choose contact and non-contact parts for your process.

Product testing, parts, and service supported through our U.S.-based facility.

Try before you buy!

Call: (979) 217-1480

Cone Valve Technology

- A cone valve is integrated into each stainless steel IBC container. When lifted, dry bulk solids and powders are accurately discharged in such a way as to avoid bridging, rat holing, and segregation that happens with traditional butterfly or slide-gate valves.

- The cone valve also provides a good level of dust containment for powders used in the pharma or specialty chemical industries.

- A dust-tight seal is made between the cone valve and actuator when the IBC is lowered onto a discharge system.

IBC Container Filling System

- Use the IBC container filling system with manual loading or automated batching.

- Load a stainless steel IBC container from a bulk silo, storage bin, or from bulk bag unloaders.

- The cyclonic design of the IBC fill head ensures maximum dust containment. The fill head is lowered once the IBC is in position. A sensor on the fill head ensures the IBC lid is removed before filling. The floor locator ensures that the IBC is placed directly under the fill head with the cone valve aligned.

- The IBC Container Filling System is also compatible with a 50 pound bag dumper.

Try before you buy!

Call: (979) 217-1480

In-Bin Blending with an IBC Tumbling Blender

- Mix and blend powders and other ingredients directly inside an intermediate bulk container using a tumbling blender. This reduces the number of product transfers and provides a sanitary mixing and blending process with minimum damage or degradation.

- The IBC tumbling blender consists of a free standing steel frame structure with a trunnion mounted rotating cage to hold the IBC. It is loaded and unloaded by a forklift truck.

- The cone valve located at the conical bottom of each stainless steel intermediate bulk container is automatically locked into place.

- Once the access gate is locked, the operator starts the tumbling blender.

- The cage rotates at a predetermined speed and duration to mix and blend ingredients inside the IBC.

IBC Discharge and Dosing System

- Safely and hygienically discharge ingredients from a stainless steel storage IBC into a blending IBC or other downstream process system like powder blending systems, IBC mixing stations, packaging, screening, conveying, or use it to refill a loss-in-weight feeder.

- As the IBC is lowered onto the discharge and dosing system, the IBC outlet engages into the station's top line and the integrated cone valve locates onto the station's central probe. This creates a dust tight seal between the intermediate bulk container and discharge system.

- When the IBC is empty, it is lifted off the discharge system and the IBC outlet remains sealed into the top liner just after the valve re-seats in the IBC outlet. This means that the product is never exposed before, during, or after discharge which is essential for food grade blending systems.

IBC Washing and Drying

- Automatically wash, sanitize, and dry intermediate bulk containers without any downtime at the production level.

- System components can include a water heater, water pressurized system, dehumidifier, and more.

Complete Powder Blending Systems using Stainless Steel IBC Containers

- Incorporate additional components and intermediate bulk containers as required to mix and blend precise powder formulations and recipes.

- Additional components and machines can also include silos, dust collectors, vacuum / pressure conveying systems, roller conveyors, packaging, bagging machines, walkways, and more.