« Equipment and Systems

-

- Open Mouth Baggers

- Valve Bag Filling Machines

- Bulk Bag Filling Machines

- Bulk Bag Unloaders

- Bag Sewing Machines

- Bag Sealing Equipment

- Bag Handling Conveyors

- Manual Palletizing Systems

- Robotic Bag Palletizers

- Gantry Palletizer Systems

- Automated Pallet Wrappers

- Automatic Bagging

Machines & Systems - IBC Blending

- Stainless Steel Intermediate Bulk Containers

Bag Sealing Equipment

Quickly close and seal many different types of bags and pouches including plastic, paper, and poly bags ranging in size from 2 oz. up to 110 lbs.

Choose from many different types of bag sealing equipment for packaging food, agricultural products, chemicals, nutraceuticals, and more. For bags and pouches under 15 lbs. in weight, we offer automatic and semi-automatic and automatic continuous bag sealers, sealers with validation, tabletop sealers, vacuum sealers with nitrogen gas flush, hermetic bag sealers, and more. For larger open mouth bags, we offer continuous bag sealers, hot air sealers, and pinch bag sealers. For valve bags, we also offer ultra sonic or hermetic bag sealers.

Click a link below to jump to a section on this page:

- Seal large bags weighing 15 lbs. - 110 lbs. or more

- Seal bags or pouches weighing 2 oz. - 15 lbs.

- Ultra sonic bag sealers for valve bags

Ask a Question or Get a Quote. Use our Express Contact Form or call: (979) 217-1480

Seal Large Bags Weighing 15 lbs. - 110 lbs. or More

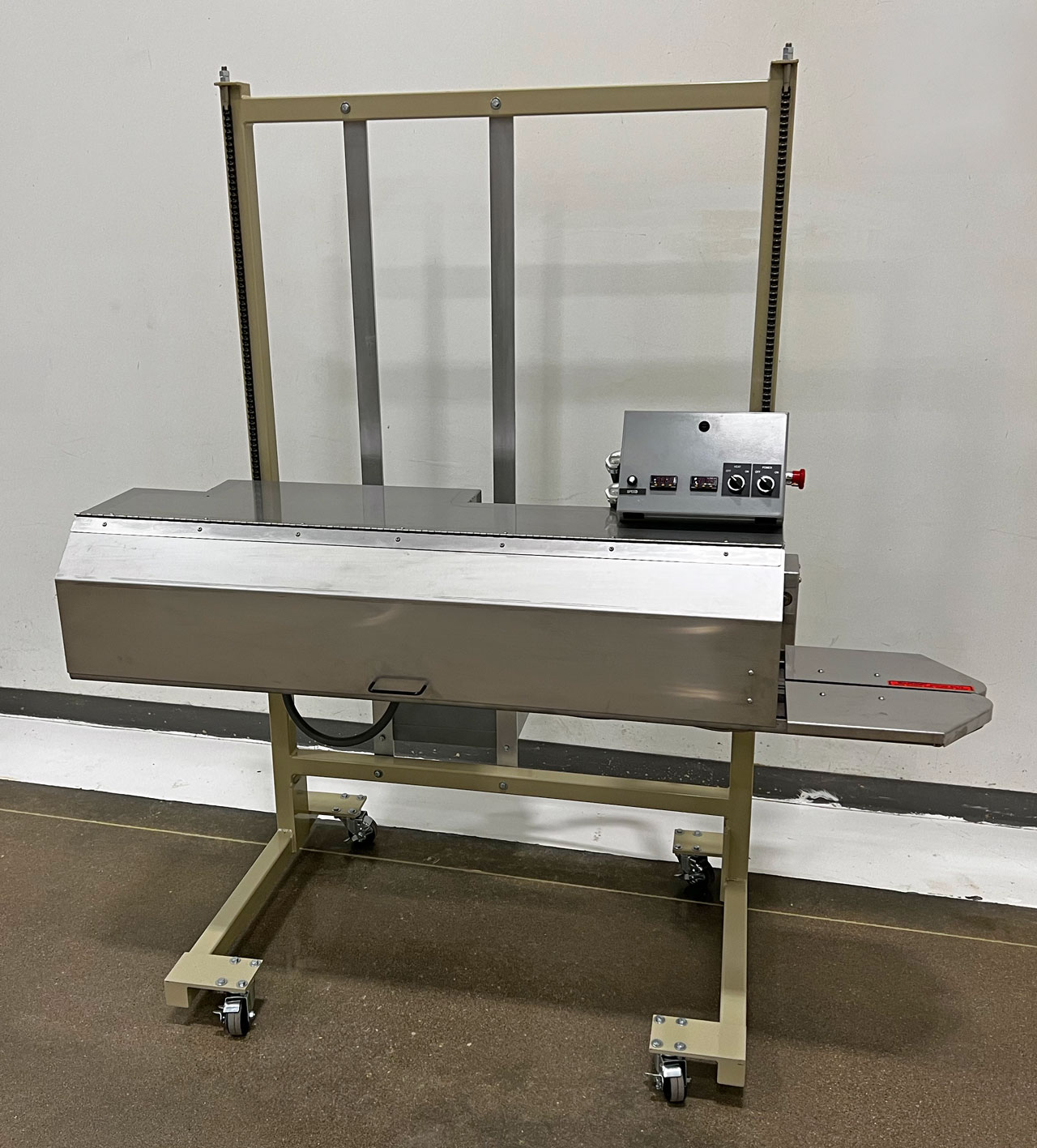

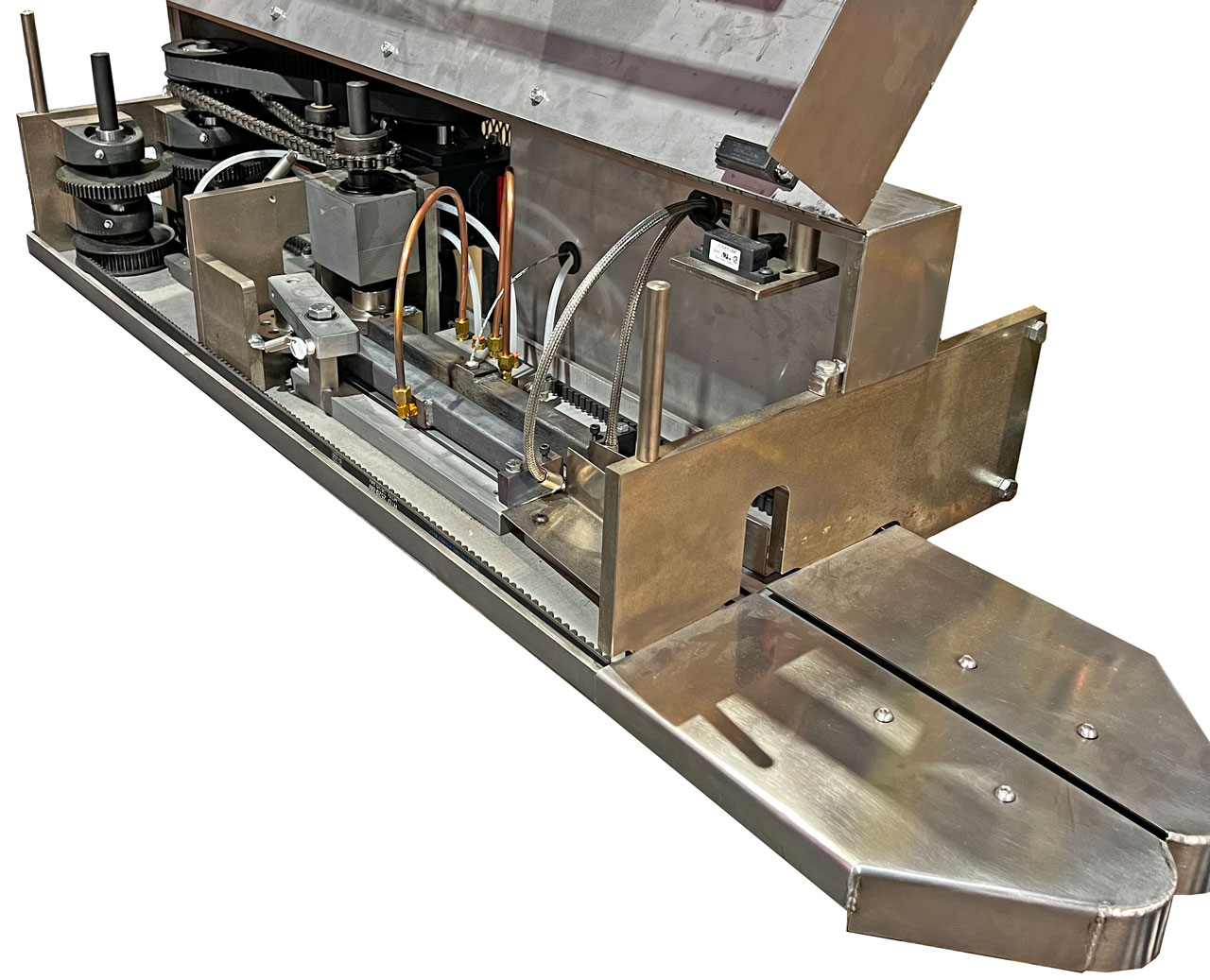

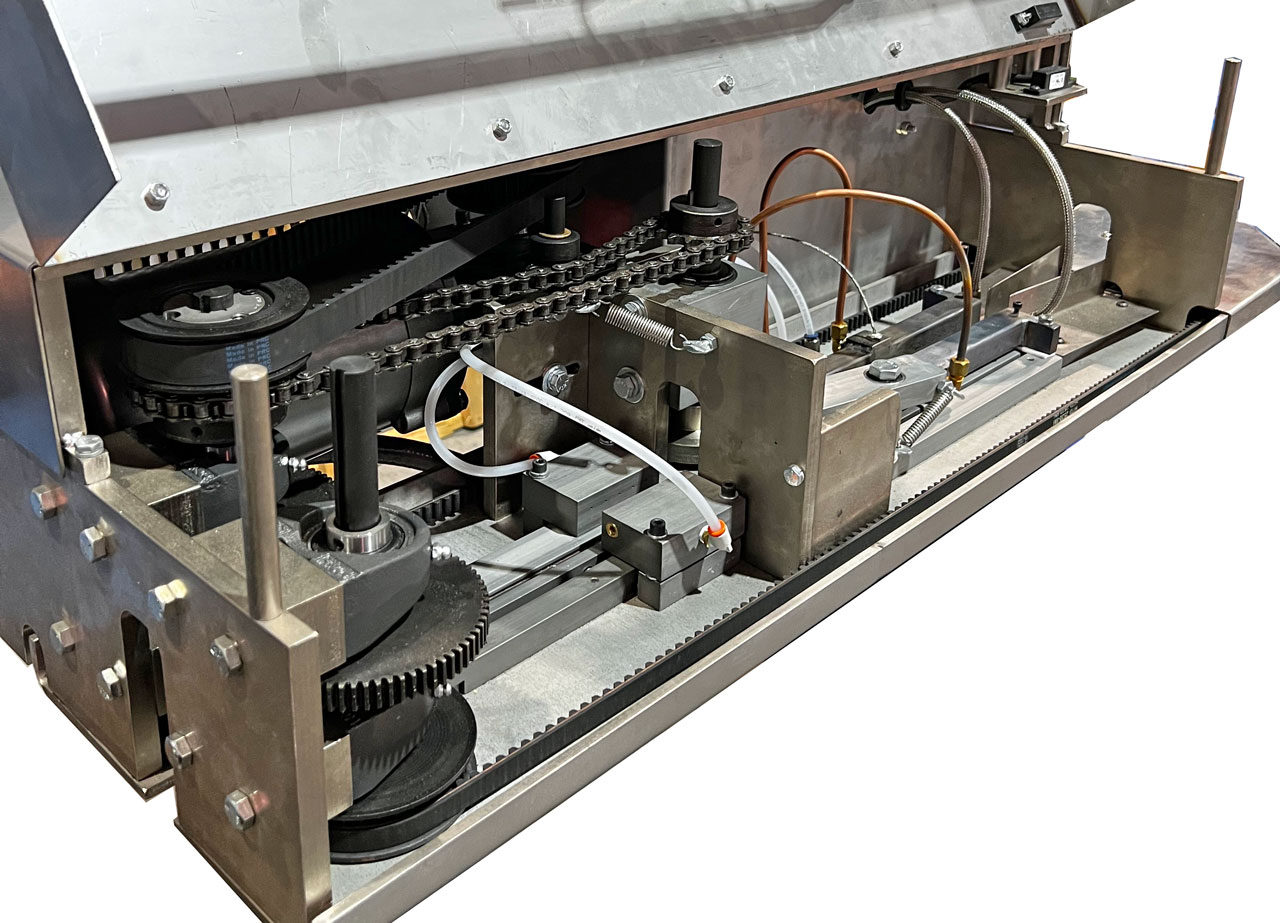

Continuous Bag Sealers

These types of industrial bag sealers, or band heat sealers, are built for reliable and automatic sealing of large open mouth bags of chemicals, salt, food, pet food, agricultural products, consumer products, military items, coffee, and more. They are ideal for both polyethylene and barrier film and are a perfect fit for those applications requiring that government regulations like MIL-SPEC and USDA packaging guidelines must be met.

Horizontal and Vertical Bag Sealers: seal nearly any weight, size, height, and type of large open mouth poly bags such as stand-up, pillow, bags on a wicket, and zippered bags

Fast: choose from multiple types of bag sealing equipment that can run up to 750+ in. per second (about 25 bags per minute) and include a synchronized conveyor

Seal Directions: all continuous bag sealers are available in right-to-left or left-to-right configurations and can be easily integrated into both manual and automatic bagging systems

Seal Thicknesses: seal up to 12mil. single thickness or 6 mil. single thickness on bags with gussets (20+ mil total)

Electrical: 110 or 220 volt / 1 phase / 60 cycle

Options Include: painted steel, stainless steel for corrosive environments, motorized pedestal, touch screen interface, and more

Get a Quote. Use our Express Contact Form or call: (979) 217-1480

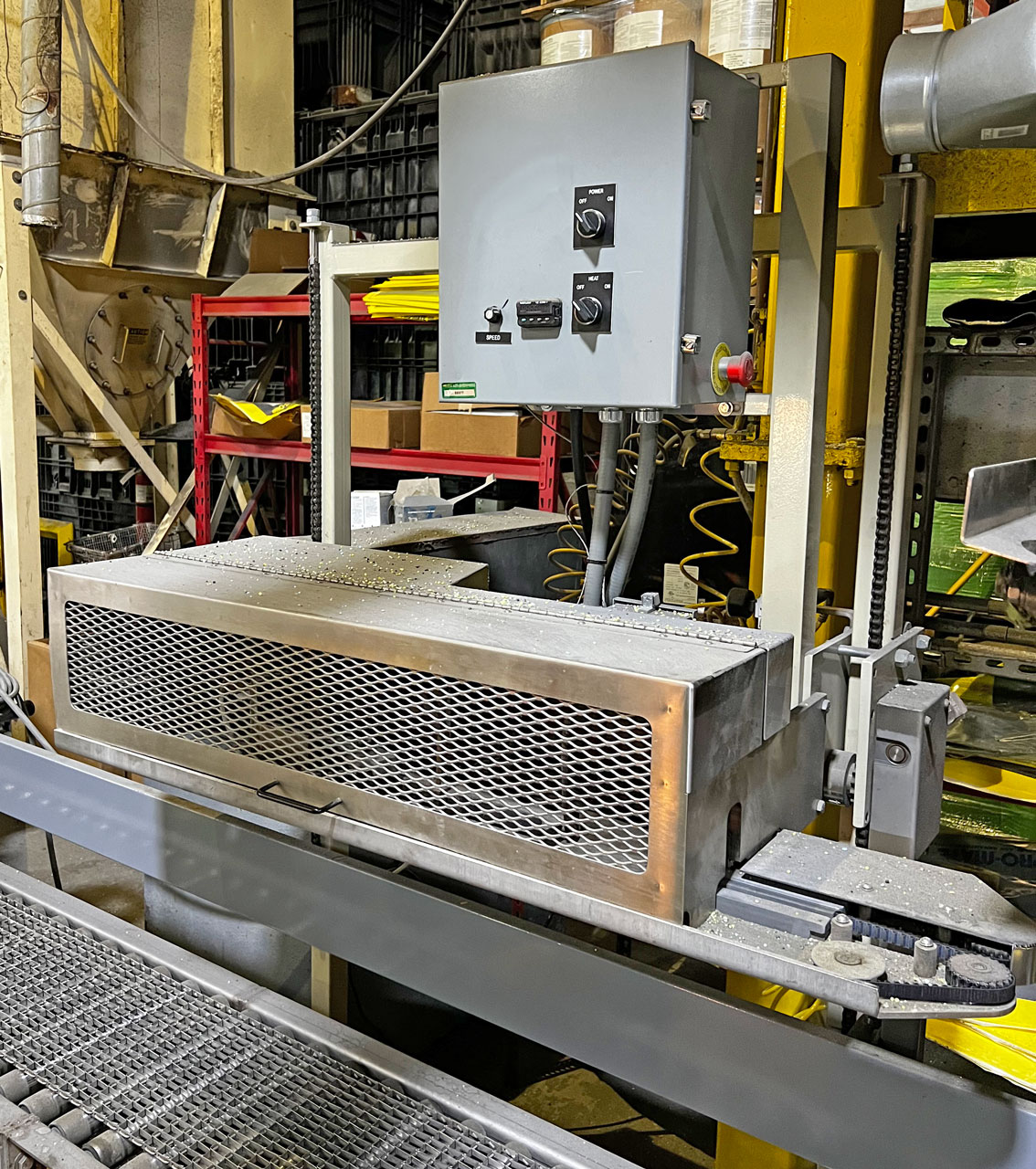

Hot Air Sealers

These hot air sealers are typically used for sealing non-gussetted, pillow-style polyethylene (PE) and polypropylene (PP) open mouth bags. However, they can be used to close and seal any pre-formed, non-gusseted, poly bags using hot air. These types of poly bags are used for packaging a wide range of products including fertilizer, pool salt, ice melt, industrial chemicals, compost, soil, etc.

Variable speed controls match the sealer and conveyor speeds for consistent and steady sealing rates. This type of bag sealing equipment can be used as a stand-alone sealer, or as a part of an automated bagging system. They have less moving parts than the continuous bag sealers mentioned above.

Horizontal and Vertical Sealers: seal nearly any weight, size, height, and type of bags such as stand-up, pillow, bags on a wicket, and zippered bags

Fast: up to 120 fpm or around 20 bags per minute

Seal Directions: all hot air bag sealers are available in right-to-left or left-to-right configurations

Seal Thicknesses: 20+ mils

Electrical: 110 or 220 volt / 1 phase / 60 cycle

Compressed Air: None required - the sealers use ambient air to seal bags

Options Include: painted steel, stainless steel for corrosive environments, motorized pedestal, touch screen interface

Get a Quote. Use our Express Contact Form or call: (979) 217-1480

Pinch Bag Sealers

These heavy duty machines close pre-glued, multiwall paper bags containing products such as food additives, pet food, pesticides, fertilizers, and more. A patented breakaway design eliminates costly downtime due to bag jams and provides easier access for cleaning. As a filled bag moves along a conveyor, the bag top is manually or automatically formed and fed into the entrance guide of the pinch bag sealer. V-belts then convey the bag top through the closer where hot air is forced against the adhesive to activate it. Then the bag passes through a series of compression rollers to compress, fold, and set the adhesive.

Bag Types: stepped end, multi-wall PBOM open mouth paper bags with pre-applied glue strip

Fast: up to 75 fpm

Seal Thicknesses: 20+ mils

Electrical: Electric (NEMA 12): 230/380/460V-3PH-60Hz, 24 VAC

Compressed Air: 7 cfm @ 90 PSI

Options Include: left-to-right operation, reverse fold - rear direction, extended infeed for automatic systems, powder coat finish or stainless steel wash down versions

Get a Quote. Use our Express Contact Form or call: (979) 217-1480

Seal Bags or Pouches Weighing 2oz. - 15lbs.

Continuous Band Sealers

Continuous band sealers provide fast, precise, and strong seals for small bags and pouches that are fed through a packaging line by hand or automatically by conveyor. They provide the highest level of seal integrity on any heat sealable and high density stand-up, gusseted, pillow, wicketed, and zippered bags.

Choose from a wide range of band sealers that fit your packaging line process:

- Standard Band Sealers: Seal a wide range of products packaged into small open mouth heat sealable bags. These machines can be customized to meet your requirements.

- Heavy Duty Band Sealers: These high-speed sealers seal products in high density / thicker bags usually weighing more than 2 lbs. that require extra strong seals at a fast rate.

- Validatable Band Sealers: These sealers are used by food manufacturers, as well as by the medical, pharmaceutical, nutraceutical, dental industries to validate a consistent seal integrity.

- Semi-automatic Band Sealers: Automatically convey bags and stand up pouches through these sealers or have multiple people hand feed this sealer.

- Tabletop Band Sealers: These types of sealers deliver high quality bag sealing for packaging lines with lower bagging rates.

Images

Click a thumbnail below to view a larger image.

- Angled band sealer

- Stand up pouches suspended from band sealer

- Sealing 20lb. Bags of Bird Seed

Need help fast?

Use our Express Contact Form to get a custom quote from our sales engineers usually in 24 hours or less!Call: (979) 217-1480

Vacuum Sealers

Vacuum sealing extends shelf life, protects against corrosion, and reduces the final volume of filled bags for more compact packages. This type of bag sealing equipment is used to hermetically seal many different types of heat sealable, high density bags and pouches at rates up to 20 bags per minute. They create a high quality, vacuumed, gas flushed seal.

- Vacuum seal bags and pouches containing coffee, snacks, baked goods, electronics, medical devices, nutraceuticals, fresh food, dried food, produce, meat, and more.

- Nitrogen gas flush systems can be added to vacuum sealers for modified atmosphere packaging (MAP) that increase protection, freshness, and corrosion resistance for moisture sensitive products like coffee or electronics.

- Use validatable vacuum sealers for medical device applications that require validation for all packaging steps.

Images

Click a thumbnail below to view a larger image.

- Vacuum sealing 4 pouches at a time

- Vacuum sealing pouches of pumpkin spice almonds

- Vacuum sealing and flushing 6 bags of coffee at a time

- Sealing 20lb. Bags of Bird Seed

Need help fast?

Use our Express Contact Form to get a custom quote from our sales engineers usually in 24 hours or less!Call: (979) 217-1480

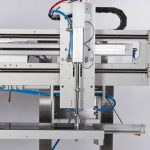

Ultra Sonic Bag Sealers

Ultra sonic bag sealers are incorporated into the framework of most valve bag filling machines.

Spout Integrated Ultra Sonic Bag Sealer

This type of bag sealing equipment is a specially designed valve bag sealer that completely eliminates the puff of dust that is commonly emitted from filled valve bags as they are discharged from the spout of the filling machine. It is commonly used when packaging food and chemical products and provides a hermetic seal that ensures a highly sanitary finished package preventing valve leakage and moisture or contaminant intrusion through the valve sleeve.

Seal rate: up to 3 bags per minute (70 feet per minute continuous seal speed)

Bag types: thermoplastic lined paper and plastic valve bags

Control air: 80 PSI

Electrical: 220 Volt / 1 Phase / 60 Cycle

Get a Quote. Use our Express Contact Form or call: (979) 217-1480