« Equipment and Systems

-

- Open Mouth Baggers

- Valve Bag Filling Machines

- Bulk Bag Filling Machines

- Bulk Bag Unloaders

- Bag Sewing Machines

- Bag Sealing Equipment

- Bag Handling Conveyors

- Manual Palletizing Systems

- Robotic Bag Palletizers

- Gantry Palletizer Systems

- Automated Pallet Wrappers

- Automatic Bagging

Machines & Systems - IBC Blending

- Stainless Steel Intermediate Bulk Containers

Automatic Bagging Machines and Systems

Ready for a bagging line upgrade?

Automate just a part of your bagging line -OR- the entire bagging system! These solutions work with open mouth bags, valve bags, and bulk bags.

Higher bagging, closing, and palletizing rates can be achieved by automating as much of the packaging process as possible. All automatic bagging machines and systems can be designed for the fewest number of people using an existing or new plant workspace and system footprint, while keeping budgetary requirements in mind.

- Increase bagging speed and production rates

- Improve accuracy and reduce product loss

- Reduce labor costs, human error, and fatigue

We have over 40 years' experience with automatic bagging machines and systems. We can custom design a system to meet your requirements. Made in the USA.

Ask a question or get a quote: Use our Express Contact Form or call: (979) 217-1480

Click a link to jump to a section below:

- Automatic Bagging Machines

- Automatic Bag Placing

- High-Speed Bag Sewing Systems, Tag Placers, and Heat Sealers

- Automatic Checkweighers, Metal Detectors, and Bag Printers

- Automatic Palletizers, Pallet Dispensers, and Slip Sheet Applicators

- Automatic Pallet Wrapping Machines

- Automatically Fill Boxes and Larger Baler Bags with Small Bags or Pouches

- Automatic Bag Destackers

1. Automatic Bagging Machines

How fast do you want to bag material? Is your current bagging scale up to speed and are you losing too much product each time you fill a bag? Are there too many points during your current fill process for human error or injury?

Every automated bagging system starts with an industrial bagging machine and scale!

Open Mouth Baggers

Fill open mouth bags and pouches weighing 1 – 110 Lbs.

Using a bagging scale like a high-speed net weigher with 1 to 3 internal weigh hoppers can greatly increase bag filling rates. These types of open mouth baggers also include a very accurate and automated digital scale control system to reduce product loss. Depending on your product, you can also add equipment like vibratory feeders or belt feeders to speed up the bulk fill rates and then increase accuracy with a dribble flow. Dust tight bag clamps automatically hold the bag to the fill spout and then release the bag onto a discharge conveyor below.

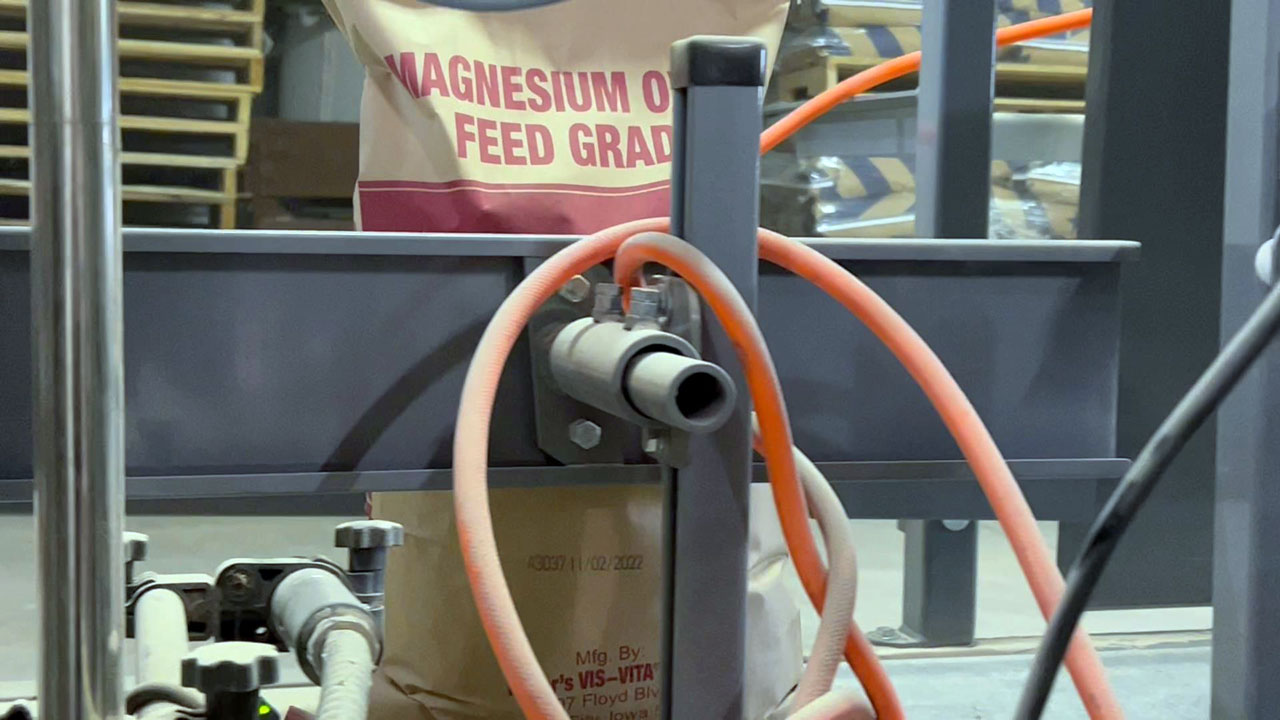

Valve Bag Filling Machines

Fill valve bags weighing 20 – 110 Lbs.

For valve bag filling machines, you can increase bagging machine automation and fill rates by adding options like automatic fill start, bag tip and drop, as well multiple fill spouts with traffic control automation on the wire mesh discharge conveyor.

Bulk Bag Filling Machines

Fill bulk bags weighing 1,000 – 4,400 Lbs.

Once a person places an empty bulk bag’s loops over automatic latches, they fit the bag’s spout over an inflatable seal and push a button to fully inflate the bulk bag to remove the creases. Then, material is discharged into the bag automatically through a valve and the weight of the material in the bag is continuously monitored by load cells. If necessary, an automatic densification deck, or vibrating table, vibrates the bulk bag. Once full, the scale controller closes the valve, automatically releases the bag loops, and deflates or disconnects the fill spout.

Need an alternative to bulk bags? Learn more about stainless steel IBC containers.

Ask a question or get a quote: Use our Express Contact Form or call: (979) 217-1480

2. Automatic Bag Placing

Remove a person (or multiple people) from a bagging line by adding an automatic bag placing machine, or robot. Automatic bag placers can pick up a bag and place or "hang" it on a fill spout. This can work in sync with an automatic bagging machine to achieve greater bag filling rates and continuous operation.

Open Mouth Bag Placers

For open mouth bags, an automatic bag placer retrieves an empty bag from a stack of bags and places it onto the spout of a bag filler. These types of machines can place large paper, plastic, or polywoven bags, or small stand up pouches and doypacks at rates up to 18 bags per minute or more. Hundreds of empty bags can be stored in a bag magazine attached to the automatic bag placer.

Valve Bag Placers

Robotic valve bag placers are designed to automatically place both paper and plastic valve bags onto the spout of a valve bag filling machine. Empty bags are moved into position from a bag magazine using an indexing conveyor. Then, they are pre-opened and tested before a robotic arm picks up each bags and places it on a valve bag filling spout. Filled bags are automatically discharged onto a wire mesh conveyor below. For increased bag filling rates, these types of robots can place bags on multiple valve bag filling machines with alternating fill and bag discharge cycles.

Ask a question or get a quote: Use our Express Contact Form or call: (979) 217-1480

3. High-Speed Bag Sewing Systems, Tag Placers, and Heat Sealers

Automate the bag closing process to greatly increase packaging system and lower labor costs. Easily convey a bag through a high-speed bag sewing system instead of manually closing bags.

High-Speed Bag Sewing Systems

Industrial high-speed bag sewing systems that are mounted on a pedestal sew bags at rates up to 20 bags per minute or more. They close multi-walled paper, woven, BOPP, and laminated woven polypropylene open mouth bags. Start-stop and thread / tape cutter photo eyes are standard, and all pedestals are factory tested prior to shipping. Additional options include thread cutter controls, thread break detection kits, and high-speed power infeeds with bag top fold over. The same person that is placing and filling bags can also feed the filled bags into the sewing system.

For even greater automation, an automatic bag top reformer is recommended to reform the top of the bag before it is automatically guided into the power infeed and sew head.

Tag Placers

Automatic tag placers can also be used with bag sewing machines. They can place and apply 3"x5", 3"x6", 4"x6", or other size tags that are sewn into each bag. Variable tag positioning is available through controller times.

Heat Sealers

Bag heat sealers can also be used to close and seal many different types of bags and pouches including plastic, paper, and poly bags ranging in size from 2oz. up to 110lbs.

For bags and pouches under 15 lbs. in weight, we offer automatic and semi-automatic continuous band sealers, sealers with validation, tabletop sealers, vacuum sealers with nitrogen gas flush, and more. For larger open mouth and valve bags, we offer band heat sealers, hot air sealers, and pinch bag closers.

Ask a question or get a quote: Use our Express Contact Form or call: (979) 217-1480

4. Automatic Checkweighers, Metal Detectors, and Bag Printers

Automatically validate fill weights, detect for tramp metal inside a bag, and print date / lot codes on bags inside of an automatic bagging system. Increase accuracy while also reducing labor costs and liabilities.

Automatic Checkweighers

Automatic checkweighers are used to check the weight of each filled bag as it passes through a bagging system. Up to 50 bags per minute or more can be checked for accuracy. Bags that don't pass a set target weight tolerance, are removed from the conveying line using a bag reject conveyor.

Metal Detectors

In-line metal detectors are used in bagging systems to identify ferrous and nonferrous tramp metal down to 0.2 mm in size. They also can activate or trigger a bag rejection machine.

Bag Printers

After passing validations, bag inkjet printers are used to automatically print lot, batch, and date codes on bags before they are palletized. Each of these unique codes helps to identify when the batch of product was produced and packaged.

Ask a question or get a quote: Use our Express Contact Form or call: (979) 217-1480

5. Automatic Palletizers, Pallet Dispensers, and Slip Sheet Applicators

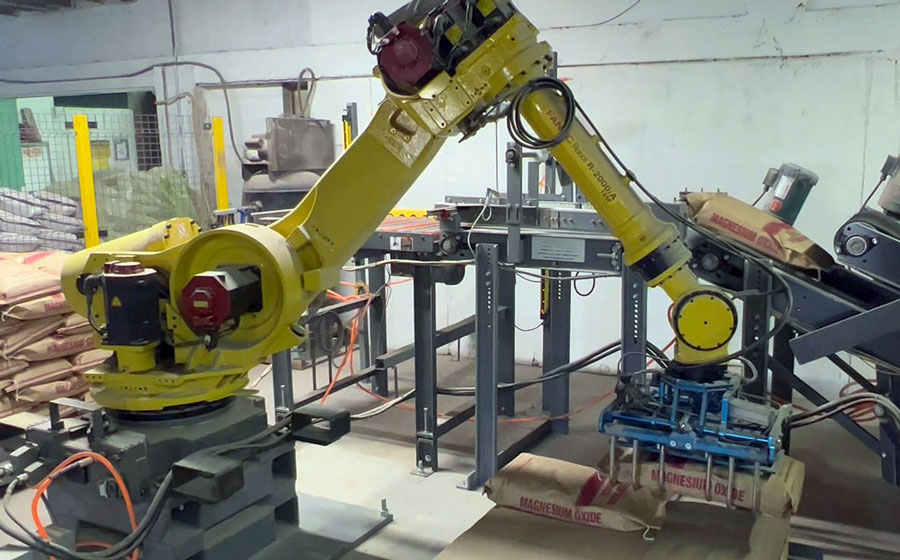

Automatic Palletizers

Automatic palletizers can greatly reduce labor costs and employee turnover. Depending on existing staffing requirements, an automatic palletizer can replace a back-breaking job usually done by multiple employees, as well as free up time spent by management staff.

Automatic palletizers can include gantry-style palletizers (or conventional palletizers) as well as robotic palletizers. They can operate 24 hours a day, seven days a week, thus eliminating the need for multiple employees at the end of a bagging line stacking heavy bags on pallets.

Once professionally set up and programmed, they require little maintenance and have much lower operating costs than teams of people manually stacking bags on pallets. They provide a consistent number of bags per pallet, bag stack patterns, and load integrity. They don’t get injured and don’t take breaks (unless automatically directed by the other components in the bagging system).

We sell new and reconditioned robotic palletizers, as well as gantry-style palletizers (or conventional palletizers) that can fit any new or existing bagging line’s footprint.

Automatic Pallet Dispensers and Slip Sheet Applicators

Increase palletizing automation by adding an automatic pallet dispenser and automatic slip sheet applicator. The pallet dispenser can hold 10 or more pallets and automatically destack and convey an empty pallet into the bag stack zone. An automatic slip sheet applicator can also be used to place a slip sheet on top of the empty pallet before it enters the bag stack zone.

Ask a question or get a quote: Use our Express Contact Form or call: (979) 217-1480

6. Automatic Pallet Wrapping Machines

Automatic Pallet Wrapping Machines

Automatic pallet wrapping machines, or stretch wrappers, are used after a palletizer in a high-speed, high-volume bagging line. They eliminate the need for a person to transport a filled pallet to a wrapping station. Once professionally installed and programmed, they also deliver a consistent and efficient amount of plastic wrap, thus reducing costs and waste while securely locking the pallet’s load in place. Plastic stretch wrap can be delivered by a rotary arm stretch wrap machine or by a conveyorized turntable.

Stand-Alone Automatic Stretch Wrappers

Not ready for fully automated stretch wrapping? We also sell stand-alone automatic stretch wrappers. A forklift operator will retrieve a full pallet from a bagging line and transport it to the stretch wrapper. Then, the person starts the automatic pallet wrapping cycle. These types of stretch wrappers are available in both a low profile for a pallet jack and high profile for forklift loading only (operators do not need to get off the forklift to operate).

Ask a question or get a quote: Use our Express Contact Form or call: (979) 217-1480

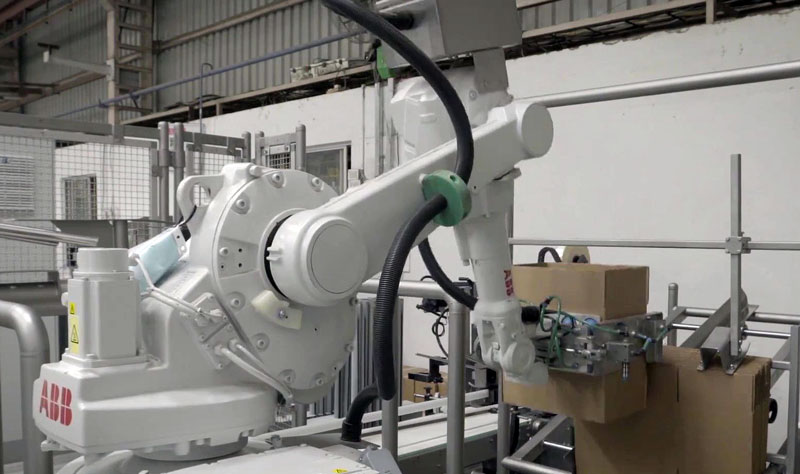

7. Automatically Fill Boxes and Larger Baler Bags with Small Bags or Pouches

Instead of palletizing bags, you can also use a robot to pick up one or multiple bags and place them into pre-assembled boxes. This type of system replaces multiple employees that would usually have to assemble boxes or baler bags and fill them by hand.

First an automatic box forming robot, or case erector, picks up a new flattened box from a vertical magazine. The robot gently squeezes the box to unfold it and then slides it over multiple rails to automatically fold, tape, and convey it to the box filling robot.

The box filling robot then picks up one or multiple filled bags and pouches and places them into the empty box. This same robot can also be used to fill larger baler bags with these smaller bags and pouches.

Ask a question or get a quote: Use our Express Contact Form or call: (979) 217-1480

8. Automatic Bag Destackers

Automatic bag destackers, or depalletizers, pick up one or multiple bags from a pallet and feed them into a downstream process. The destacker’s system relies on computer vision to detect and lift / place bags. The robotic arm is fitted with end of arm tooling that uses zoned vacuum suction to lift the bags off the pallet.

Once all the bags have destacked, the empty pallet is automatically conveyed to an empty pallet collection system.

Ask a question or get a quote: Use our Express Contact Form or call: (979) 217-1480