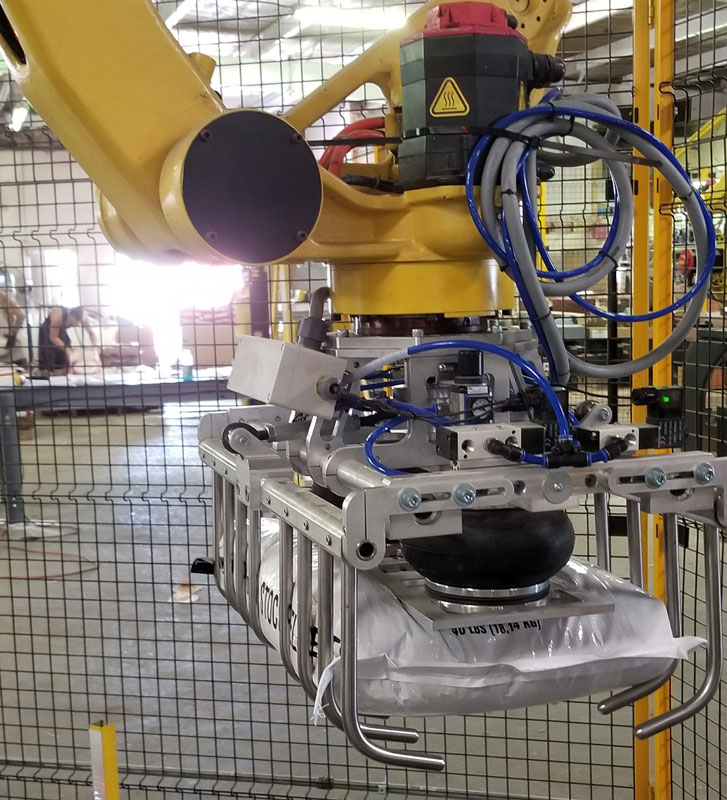

The video below shows a pallet stacking robot stacking 50 lb. paper valve bags onto a pallet located on the floor per the programmed bag placement design. This robot was added to an existing bag filling system to reduce labor costs and increase automation.

Watch a Video:

Frequently Asked Questions

How does a pallet stacking robot fit into an existing bagging system?

Due to their small footprint, pallet stacking robots, or robotic palletizers can be retrofitted into just about any type of bag filling system. In the video shown above, the robot arm is centered between two bag palletizing stations, one on the right side and the other on the left side. Filled bags are picked from the conveyor and stacked on the left side until the pallet is filled. Then, the robot switches to the right side and stacks bags until that pallet is filled. A fork truck operator enters the right or left side as needed to remove a filled pallet and to place an empty pallet on the floor. This type of system is usually referred to as semi-automatic because approximately 80% of the palletizing process is automated.

Based on past experience, we find that automated palletizing systems yield the biggest return on investment!

How much floor space does a palletizing robot require?

Ballpark number is a 20 foot by 20 foot area.

What bag sizes or weights can be stacked with these types of robots?

Pallet stacking robots stack valve bags and open mouth bags weighing 20-110 lbs. If you want to palletize different sized bags with the same bag filling system, end-of-arm tool change out is required. This type of robot arm can also stack pails, boxes, and drums on shipping pallets.

NEW! – For floppy bags filled loosely with products such as animal feeds, grains, seeds, fertilizers, minerals, aggregate, sand, rocks, potatoes, onions, and more…check out the Gantry Palletizers Systems page for affordable alternatives to traditional robotic arm palletizers.

How does a robot stacker pick up the bags without breaking them?

It uses an attachment, or end-of-arm tool, that reaches under the bag when it is on the robot pick conveyor.

How does a pallet stacking robot know when to start and stop?

There are a series of electronic sensors along the infeed conveyors that send a signal to the robotic arm processing computer. These signals inform the robot arm of the location of the incoming filled bags on the conveyor.

Is it difficult to learn how to use one of these robots?

For the operator, there is no learning curve. All bag stacking “recipes” will be preprogrammed into a very simple touch screen interface. There is nothing else to do once everything has been programmed.

In a semi-automatic bag palletizing system, the only action an operator will perform would be to remove the filled pallets and replace them with empty pallets.

How are updates made to the pallet stacking robot’s software?

Updates may be required if the bags change or if the pallet size changes, but usually no updates are required.

Do you have to make a lot of adjustments over time because things “get out of whack”?

No, the robotic arm is a very accurate and reliable piece of equipment. If any minor adjustments need to be made, this can be accomplished by in-house maintenance staff. If any larger adjustments are needed, we can usually assist with a phone call support.

Can a robot stacker operate in a dusty environment?

We recommend that operators spend 10-15 minutes every day to clean up around the palletizing area. This would be a simple sweep around the area. If the equipment is operating in an extremely dusty environment, it would be good practice to use compressed air to blow off the conveyors, optical sensors, and end of arm tool once a day to prevent any issues.

Can a robot be moved easily if you want to use it in another location of the factory or at an entirely off-site location?

Moving a robot would be a medium size to large size project, depending on all of the equipment involved. It would require all electrical connections to be disconnected, removing anchoring hardware, moving the equipment, and reinstalling in a new area. This system is not considered portable.

Will a pallet stacking robot work in very hot or cold locations in Texas, Oklahoma, Arkansas, Louisiana, etc.?

Yes, the robots will work in cold or hot locations (appx. 35°F-125°F). Temperature does not affect performance.

Watch a Video:

Need pricing fast or have a question?

Use this express contact form! A Tinsley Equipment Company sales engineer will email you current pricing for all equipment and system components listed on this page usually within 24 hours or less. Need to speak with someone? Call: (979) 217-1480

* All fields are required.