This system is used for bagging salt into 40 Lb. poly bags. It includes a hopper, net weigh bagging machine, band sealer, and manual bag stacking station with pallet wrapper machine.

Watch a Video

Process Description

Salt flows freely by gravity from the 200 cubic foot supply hopper bin into the top of the net weigh bagging machine. When a fill cycle is started, salt is automatically metered and pre-weighed into an internal weigh hopper within the bagging machine.

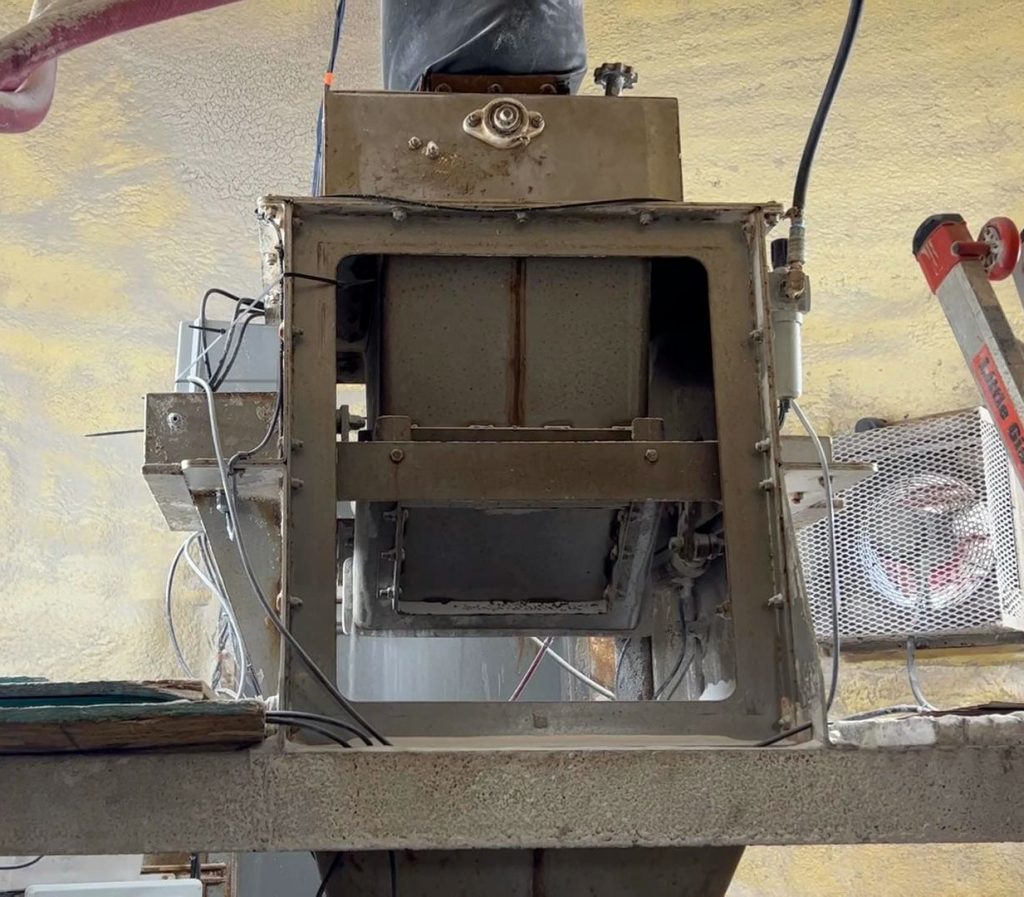

View of internal weigh hopper in net weigh bagging machine

When an operator or automatic bag placing machine provides a signal to the machine, the pre-weighed amount of salt discharges into the poly bag. Once full, the bag clamp releases the bag onto a bag closing conveyor, where the operator guides it through a band heat sealer.

Heat band sealer used to close poly bags

After sealing, the bag is conveyed to a manual palletizing station. Another operator then picks up the bag and places it on pallet that has a pre-applied cardboard box to contain any salt that might spill from the bags.

Palletizing station at end of bagging line

Once a pallet is full, an operator with a forklift or floor jack takes it to a pallet wrapper machine.

Full pallet with bags of salt on pallet wrapper machine

Additional opportunities for Automation and Labor Cost Savings

This system could be further automated by adding the following:

Ready to add a similar type of system to your packaging line?

Ask a Question -or- Get a Price Quote

Call: (979) 217-1480