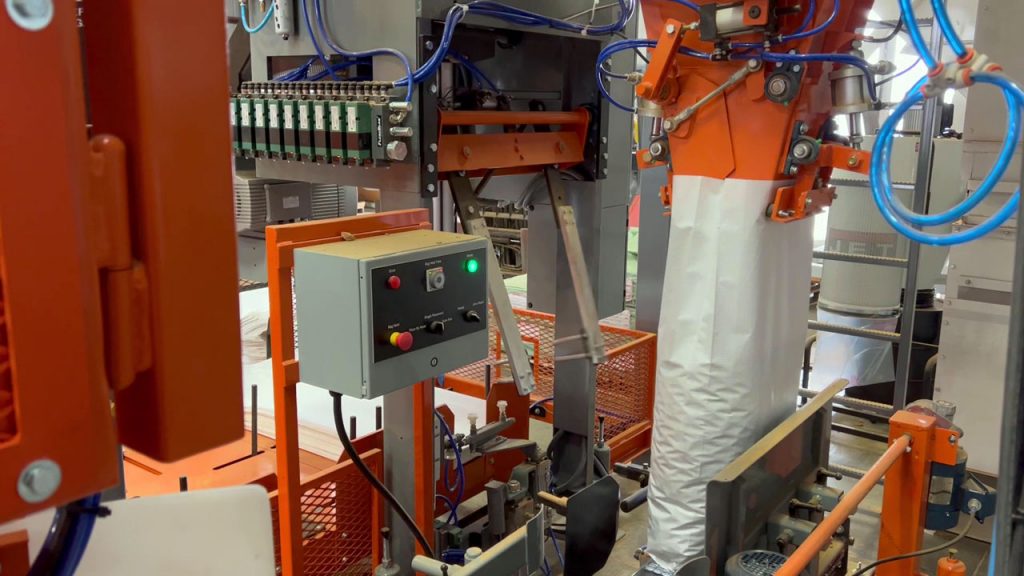

This automatic bagging machine fills plastic bags with different blends of bird seed. After filling, the bags are automatically sealed, palletized, and boxed. The video shows 20, 30, and 40 lb. bags of bird seed being filled and sealed.

NEED HELP FAST? We have over 40 years' experience with Bulk Material Handling, Packaging, and Processing. (979) 217-1480 GET A QUOTE

NEED HELP FAST? (979) 217-1480 GET A QUOTE

Open mouth bagging machines weigh and fill different types and sizes of bags and containers with bulk solids and products that are powders, flakes, granules, and irregular shaped pieces. The filled bags and containers usually usually weigh 20 lb. - 110 lbs. There are many different types of open mouth bagging machines including manual, semi-automatic, and automatic versions with filling speeds up to 24 bags per minute (50 lb. bagging machines being the most popular). Once the bags have been filled, they are usually moved through a bag sewing or sealer machine. Then, they are conveyed to a station, where the bags are palletized, stacked, and wrapped for shipping, storage, and sale.

Ask a question or Get a Price Quote. Use our Express Contact Form or call: (979) 217-1480

To give you a good idea about the types of open mouth bagging machines and systems that are available, we have included descriptions, images, and videos from past installations. Learn more about filling plastic and paper bags with products like deer corn, seeds, cattle feed, fertilizer, wood pellets, flour, mixes, sugar, sand, pellets, chemical powders, and more. We have tried to include as many details as possible including how fast you can fill bags, how each machine operates, and how bag closing works.

Category | Automatic Bagging Machines | Open Mouth Bagging Machines |

This automatic bagging machine fills plastic bags with different blends of bird seed. After filling, the bags are automatically sealed, palletized, and boxed. The video shows 20, 30, and 40 lb. bags of bird seed being filled and sealed.

Category | Open Mouth Bagging Machines |

This system precisely unloads free-flowing seeds, feed, corn, and more from a Buckhorn CenterFlow seed pro box into open mouth bags using an open mouth bag filler. The system can also be used to bag other free-flowing agricultural products like bird seed, wheat seed, deer corn, animal feed, fertilizer, pellets, and more.

Category | Automatic Bagging Machines | Bag Handling Conveyors | Bulk Bag Unloaders | Bulk Processing Equipment | High Speed Robotic Palletizers | Industrial Mixers | Open Mouth Bagging Machines | Small Bag Fillers | Small Vibratory Feeders |

Automate your candy and chocolate production lines and processes!

New or existing candy and chocolate production lines can be fully automated and equipped with control systems on all processing units.

Category | Automatic Bagging Machines | Bag Handling Conveyors | High Speed Robotic Palletizers | Open Mouth Bagging Machines |

Pallets stacked by 2 robotic palletizers are automatically conveyed into one stretch wrapper. A hood is also applied during wrapping.

Category | Bag Sewing Machines and Heat Sealers | Open Mouth Bagging Machines |

This fertilizer bagging system is used to fill poly bags with granular, free-flowing fertilizer. It includes a specially designed discharge stand and stainless steel hopper for Buckhorn CenterFlow seed boxes, a stainless steel digital gross weigh bagging scale with pneumatic bag clamp, a stainless steel mesh belt bag closing conveyor, and a hot air bag sealer.

The same type of system could be used to bag other types of free-flowing products like animal feed, plastic pellets, grains, seeds, wood pellets, and more. Multiple bag filling recipes are stored and easily swapped out via the digital scale controller.

Category | Bag Handling Conveyors | Bag Sewing Machines and Heat Sealers | Open Mouth Bagging Machines |

The Grain and Corn Bagging System combines product storage, filling, and bag closing into one system. Efficiently fill and close 30-50 lb. paper and poly-woven open mouth style bags.

The Grain and Corn Bagging System combines product storage, filling, and bag closing into one system. Efficiently fill and close 30-50 lb. paper and poly-woven open mouth style bags.

The system has been engineered for bagging deer corn (whole corn), feed, seed, and other grains. The manual, or mechanical, bagging option includes automatic weighing. The system is upgradeable to a higher packaging speed with the addition of a high-speed bag sewing system to quickly close the bags. Additional options are available including hand held bag sewing machines, bag flattening conveyors, and bag stacking systems.

Category | Automatic Bagging Machines | High Speed Robotic Palletizers | Open Mouth Bagging Machines |

View of Bagging Machine and High-Speed Bag Closer in an Automated Packaging System

Rice producers face several challenges when it comes to bagging and packaging their product. Manual bagging processes can be time-consuming, labor-intensive, and prone to errors. To overcome these challenges, a USA-based rice producer sought an automated packaging system that could increase production efficiency, reduce labor costs, and improve bagging accuracy. In this case study, we’ll examine how the company successfully implemented the system, resulting in significant time and cost savings.

Category | Bulk Bag Unloaders | Open Mouth Bagging Machines |

This simple system is used to safely unload bulk feed tote bags (also called FIBC, bulk bags, Super Sacks®, or jumbo sacks) containing dry, free-flowing products by gravity into an open mouth bagging machine and scale. The bagging machine would then weigh out a desired amount of feed into each open mouth bag, with 40lb. and 50lb. bags being the most popular. This system is custom engineered for repackaging and down packing businesses.

This simple system is used to safely unload bulk feed tote bags (also called FIBC, bulk bags, Super Sacks®, or jumbo sacks) containing dry, free-flowing products by gravity into an open mouth bagging machine and scale. The bagging machine would then weigh out a desired amount of feed into each open mouth bag, with 40lb. and 50lb. bags being the most popular. This system is custom engineered for repackaging and down packing businesses.

Category | Open Mouth Bagging Machines |

Tinsley Equipment Company recently performed a test run for a new feed producer that was interested in bagging horse pellets into 25 lb bags.

These type of supplement horse pellets were made of coastal hay and measured about ¼-1/2” in diameter and about 1 inch long. The producer farms different types of coastal hay and Bermuda grasses and wanted to learn more about the bagging and packaging process.

Horse pellets (or hay pellets) used for feed supplement

To run the test, Tinsley Equipment Company set up a 25 cubic foot bagger supply hopper, a digital gross weigh bagging machine with a pneumatic bag clamp, a temporary box platform under the scale to support the filled bag, and then a table for manual bag top folder over and handheld sewing. Closed bags were manually transported and stacked on pallets resting on a truck trailer. Finished pallets were manually wrapped and secured to the trailer before transporting them to a feed store for final sale.

Category | Automatic Bagging Machines | Bulk Processing Equipment | Open Mouth Bagging Machines |

Lot / batch code and date printed on bottom part of bag after passing print head

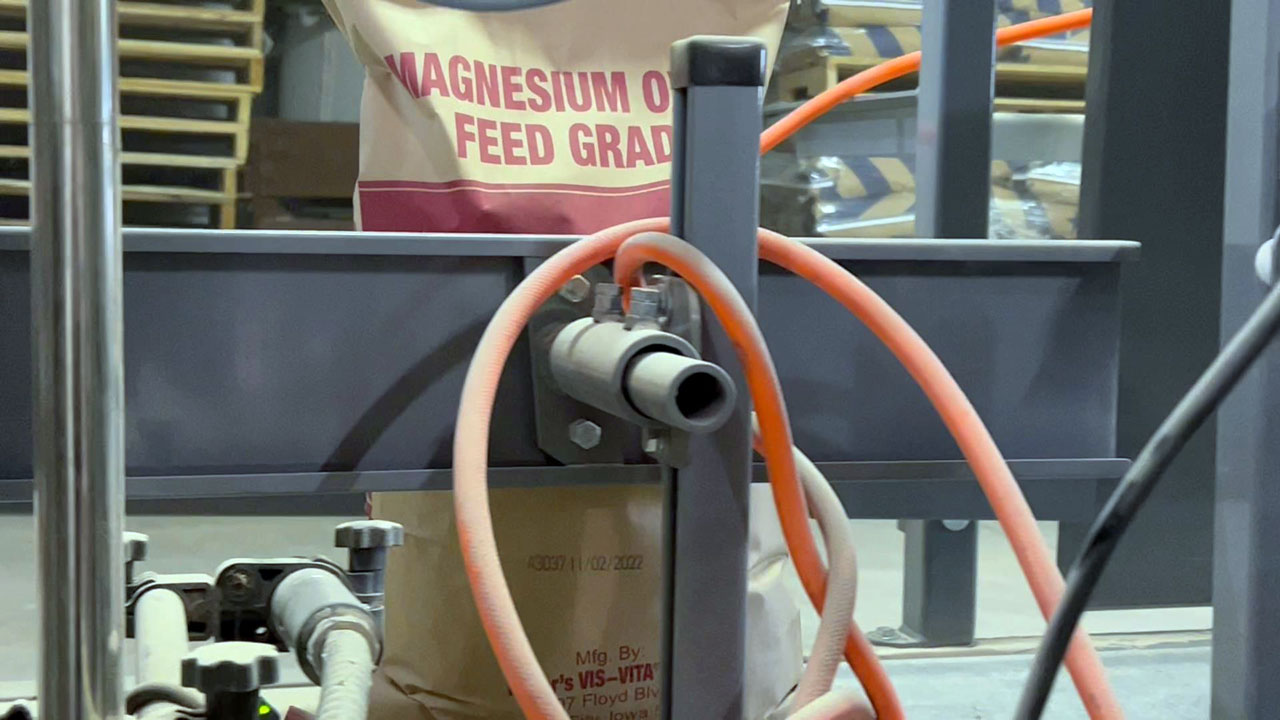

This inkjet code printer was put to the test in an animal feed and minerals packaging line. Multi-wall open mouth paper bags, filled with animal feed are sewn shut. Then, they pass in front of the code printer on a conveyor before robotic palletizing. As each bag passes the code printer, a lot code and date are printed on the bottom part of the bag. Each of these unique codes helps to identify when the batch of product was produced and packaged.

Category | Open Mouth Bagging Machines |

This system is used for bagging salt into 40 Lb. poly bags. It includes a hopper, net weigh bagging machine, band sealer, and manual bag stacking station with pallet wrapper machine.

Category | Open Mouth Bagging Machines |

A co-op in Iowa replaced their existing bagging machine with a high-speed net-weigher used to fill 50Lb craft paper bags with cracked corn and pelleted feeds.

High-speed bagging machine added to existing packaging system

This cooperative grinds approximately 50,000+ bushels of corn per day at all of their feed mills. They primarily supply swine feed, but also produce cattle feed and dairy feed.

Category | Automatic Bagging Machines | Open Mouth Bagging Machines |

The automatic bag placer machine picks up, hangs, and clamps an empty open mouth bag onto a bagger before product is discharged into a bag. Up to 20 bags per minute are possible and it works with both new / existing net weigh and gross weigh bagging scales. With this type of automation, one full-time operator can be removed from the bagging system.

Category | Bulk Bag Unloaders | Open Mouth Bagging Machines |

Packaging system fills open mouth paper bags at a rate of 4-6 bags per minute with granular and powder products, such as zeolite and guar gum.

The system repackages products from big bags, also called bulk bags or Super Sacks®. It includes a forklift loaded bulk bag unloader with an extended frame to accommodate an open mouth bagging machine underneath.