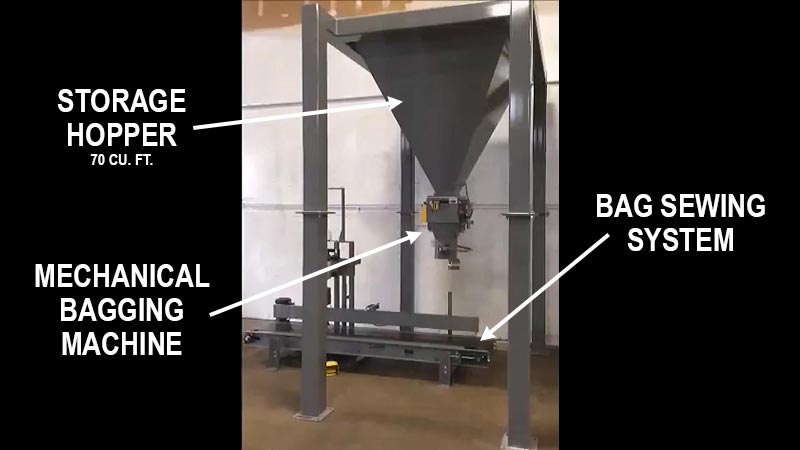

The Grain and Corn Bagging System combines product storage, filling, and bag closing into one system. Efficiently fill and close 30-50 lb. paper and poly-woven open mouth style bags.

The Grain and Corn Bagging System combines product storage, filling, and bag closing into one system. Efficiently fill and close 30-50 lb. paper and poly-woven open mouth style bags.

The system has been engineered for bagging deer corn (whole corn), feed, seed, and other grains. The manual, or mechanical, bagging option includes automatic weighing. The system is upgradeable to a higher packaging speed with the addition of a high-speed bag sewing system to quickly close the bags. Additional options are available including hand held bag sewing machines, bag flattening conveyors, and bag stacking systems.

Click a link below to jump to a section:

- Mechanical Gross Weigh Bagging Machines

- 4 Bag Sewing System

- Bag Palletizing System

- Hoppers

- Additional Options

- Get a Price Quote or Ask a Question

Mechanical Gross Weigh Bagging Machines

The mechanical gross weigh bagging machine is a gravity-style open mouth bagger for filling 30-50 lb. bags with deer corn, feed, seeds, and other free-flowing agricultural products.

- Fill 200 bags per hour or 4 bags per minute (for faster fill rates of 300 bags per hour or 6-7 bags per minute, we recommend upgrading to a digital gross weigh bagging scale with a pneumatic bag clamp.)

- Simultaneously fills and weighs product directly into paper and poly-woven open mouth style bags

- No electricity or compressed air required for basic operation

- Bulk flow only (no dribble flow)

- Cam grip bag spout (mechanical)

- Available with 22 or 29 in. spout circumference

- Powder coated mild steel

- For even easier set up and adjustments, upgrade to digital controls with auto tare and fill weight memory.

Types of products that can be packaged with this bagging machine: whole corn or shelled corn, deer corn, grain, seed, flour, rice, soybean, cattle feed, bird seed, sugar, salt, fertilizer, ice melting salt, PVC resin, plastic pellets, wood pellets, activated carbon, pea gravel, sand (dry)

Mechanical gross weigh bagging scale attached to 70 cubic foot hopper

Mechanical bagging machine with 29 in. circumference attached to Pro Box bin discharge stand

4 Bag Sewing System

Heavy duty, variable speed, filled bag closing conveyor with adjustable height, back rail, and pedestal-mounted sewing head for use by a single operator.

Heavy duty, variable speed, filled bag closing conveyor with adjustable height, back rail, and pedestal-mounted sewing head for use by a single operator.

System includes:

- 8 ft. long by 12 in. wide bag closing conveyor

- 18-21 in. adjustable conveyor height

- Digital variable conveying speeds with automatic start and stop

- Adjustable back rail

- 6 in. structural C-channel with powder coated frames

- Sewing head with self-standing adjustable mounting pedestal and 1 cone of thread

New! Don’t want to sew bags shut? We also offer a Grain Bagging System that fills self-sealing valve bags with corn and other types of free-flowing grains at 6-8 bags/min.

Bag Palletizing System

Incline conveyor takes 50# bags of corn up to a gravity roller table to be stacked on a pallet

Use a manual assisted bag palletizing system to stack open mouth bags containing a variety of products.

System includes:

- Incline Bag Conveyor – 10 foot x 24 inch wide belt

- GRT Gravity Roller Table – 3 foot long by 27 inch wide

bag or box stacking conveyor, includes stop plate and adjustable height support legs at OSHA recommended palletizing heights. - EZ Pallet Loader – pneumatic rotating table for pallet loading and unloading

Want to go automatic? We sell reconditioned robotic bag palletizers and conventional palletizers at entry-level prices.

Watch a Video of a Mechanical Gross Weigh Bagging System

Hoppers

Professionally manufactured, high-strength, and 2-part epoxy coated hoppers work seamlessly with bagging equipment. Hopper options include:

Professionally manufactured, high-strength, and 2-part epoxy coated hoppers work seamlessly with bagging equipment. Hopper options include:

- 25 cubic foot bagger supply hopper with 4 inch square legs, 8 inch foot pads

- 70 cubic foot bagger supply hopper with 6 inch tube steel frame and 3/16 inch wall thickness

- Buckhorn Pro Box / Bin discharge stand

- Additional custom sizes and extensions are available

Mechanical gross weigh bagging machine attached to 25 cubic foot hopper with 4 Bag Sewing System

Note: Bolt on lids are sold separately. All interior and exterior welds are continuously welded. Finishes requiring grinding and finishing of interior welds will be quoted. For products weighing 100 lbs. per cubic ft. or greater, additional bracing or support structure may be required and quoted separately.

Need pricing fast or have a question?

Use this express contact form! A Tinsley Equipment Company sales engineer will email you current pricing for all equipment and system components listed on this page usually within 24 hours or less. Need to speak with someone? Call: (979) 217-1480

* All fields are required.

Additional Options:

Handheld Bag Sewing Machine

- Handheld sewing head only

- No pedestal or conveyor

- Can be used independently or as a spare for the pedestal mounted bag sewing system

- Add and optional spring balancer for gentle retraction to an ergonomic height

Digital Gross Weigh Bagging Scale

All digital weight control with user-friendly interface allows for quick and easy weight adjustment. Includes advanced functions like automatic tare and secondary set points.

All digital weight control with user-friendly interface allows for quick and easy weight adjustment. Includes advanced functions like automatic tare and secondary set points.

- Fill rates of 300 bags per hour or 6-7 bags per minute using a digital gross weigh bagging scale with a pneumatic bag clamp

- Digitally controlled gravity flow bagging machine

- Digital controller with auto tare

- Bulk and dribble flow

- Automatic bag clamp

- Available with 22 or 29 in. spout circumference

Watch a video of a Digital Gross Weigh Bagging Scale System

This bagging system unloads whole corn from a Buckhorn Pro Box container into an open mouth bag. It uses the digital gross weigh bagging scale with a pneumatic bag clamp an can fill approximately 300 bags per hour, or up to 6-7 bags per minute with corn.

EZ Pallet Loading Station

Save your back and reduce fatigue with a pallet loading station (scissor lift pallet jack) that is designed to assist with the manual palletizing of filled bags.

Save your back and reduce fatigue with a pallet loading station (scissor lift pallet jack) that is designed to assist with the manual palletizing of filled bags.

- Self raising / lowering

- 360 degree rotating work platform

- Designed for loads up to 4,000 pounds

Learn more about palletizing machines and robots.