Automate your candy and chocolate production lines and processes!

New or existing candy and chocolate production lines can be fully automated and equipped with control systems on all processing units.

NEED HELP FAST? We have over 40 years' experience with Bulk Material Handling, Packaging, and Processing. (979) 217-1480 GET A QUOTE

NEED HELP FAST? (979) 217-1480 GET A QUOTE

Industrial mixers play a crucial role in various industries, including food, pharmaceuticals, and construction. They are designed to blend, condition, and mix large batches of products quickly and efficiently. These mixers can handle a wide range of materials, from powders and spices to refractory castables and industrial bi-products.

Sanitary mixers, also referred to as food grade mixers, are constructed with an emphasis on cleanliness. These types of industrial mixers are equipped with stainless steel surfaces that come into contact with the product, which are devoid of any cracks or crevices, ensuring the integrity of food, chemical, and pharmaceutical products. They can be either single or twin shaft, equipped with ribbon or paddle agitators, and their interior surfaces can be polished to a 120 grit final finish.

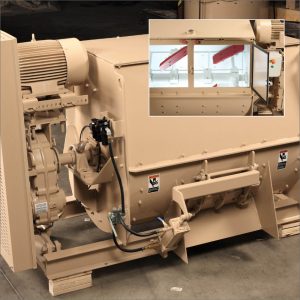

Pug mill mixers are robust continuous mixing systems capable of processing both damp and dry materials. They can manage volumes ranging from 50 to 400 tons per hour. Each pug mill is equipped with two independent mixing shafts, each powered by its own motor, v-belt, and gear reducer, allowing for sequential starting.

Industrial paddle mixers are available in two variants: single or twin shaft. Single shaft mixers can handle smaller quantities of products, up to 8 tons per hour, while their twin shaft counterparts are designed for mixing very large batches. These types of industrial mixers are capable of managing a wide range of materials, including dusty, powdery, hazardous, and non-hazardous substances.

Turbin mixers are renowned for their efficiency and productivity, making them the go-to choice for processing dust and other types of fine, powdery, hazardous, and non-hazardous materials. These types of industrial mixers provide a three-dimensional mixing action that can produce a non-dusting material in as little as 30 seconds with a minimum of 8% water (or another reagent). Turbin mixers are available in 8 different sizes, with processing rates ranging from 8 to 200 tons per hour.

Refractory mixers are tailor-made to cater to the specific requirements of the refractory industry and refractory castables. These types of industrial mixers can handle wet or dry batches of materials, regardless of their shape or size. They boast a low-profile design that can be integrated into new or existing plants and offer a remarkably quick mixing cycle due to their horizontal pan-type design and rapid opening discharge door.

Planetary mixers are pan-style mixers with counter-rotating mixing arms. They can mix wet or dry material, achieving a uniform mix in as little as 30 seconds. These mixers can be equipped with up to four discharge doors, facilitating the distribution of material to different workstations or downstream processing equipment.

Our product line of industrial mixers includes food grade and sanitary mixers, paddle mixers, planetary mixers, turbin mixers, and refractory mixers. Pug mills are also available but not recommended as pan style batch mixers are now the industry standard.

For in bin IBC blending and mixing of recipes and powders, please see the IBC blending, batching, and mixing line of machines and systems.

Ask a question or Get a Price Quote. Use our Express Contact Form or call: (979) 217-1480

Category | Automatic Bagging Machines | Bag Handling Conveyors | Bulk Bag Unloaders | Bulk Processing Equipment | High Speed Robotic Palletizers | Industrial Mixers | Open Mouth Bagging Machines | Small Bag Fillers | Small Vibratory Feeders |

Automate your candy and chocolate production lines and processes!

New or existing candy and chocolate production lines can be fully automated and equipped with control systems on all processing units.

Category | Industrial Mixers |

Foundries have extensive dust collection systems throughout their plants. Most of the collected dust is disposed of at a landfill. Prior to leaving the foundry, the dust is sometimes required to be conditioned to a dustless mixture before a landfill will accept it. This can be accomplished using an industrial mixer such as a large paddle mixer, Turbin mixer, or planetary style mixer.

Foundries have extensive dust collection systems throughout their plants. Most of the collected dust is disposed of at a landfill. Prior to leaving the foundry, the dust is sometimes required to be conditioned to a dustless mixture before a landfill will accept it. This can be accomplished using an industrial mixer such as a large paddle mixer, Turbin mixer, or planetary style mixer.

Category | Bulk Bag Fillers | Bulk Bag Unloaders | Industrial Mixers |

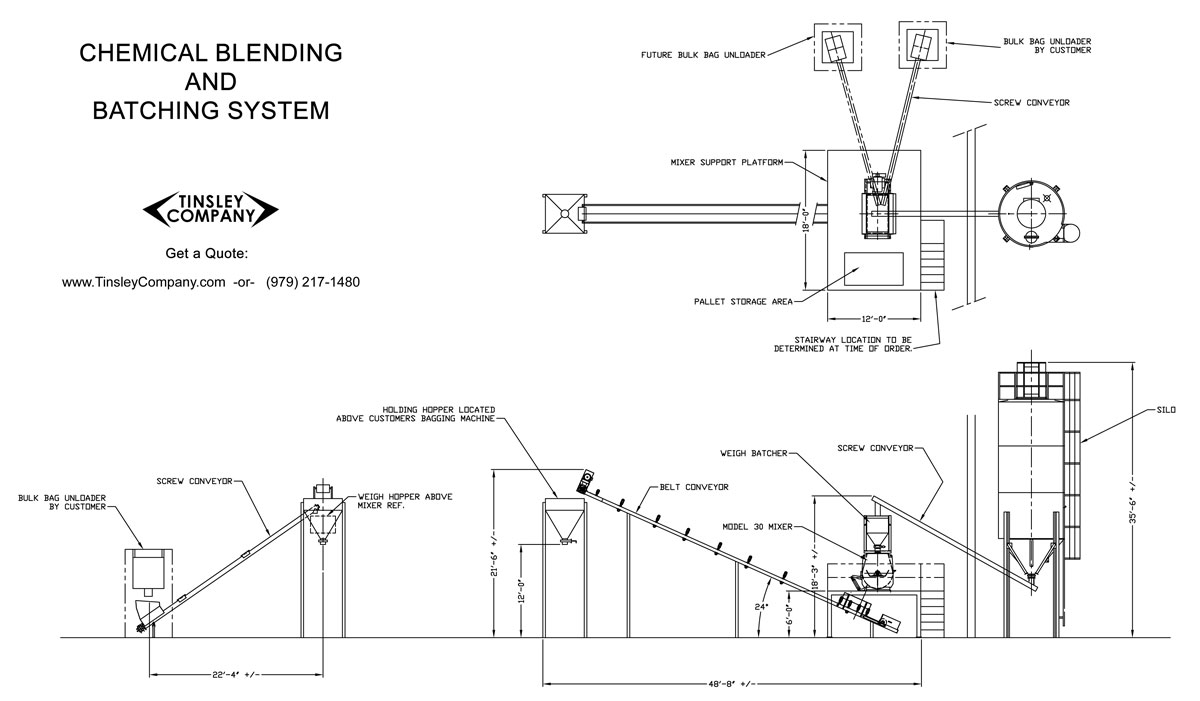

This chemical blending and batching system was used for the toll blending of powder chemicals, including calcium carbonate. The final blended product was to be automatically packaged into bulk bags using a bulk bag filling machine. It could also be packaged into smaller bags using a valve bagging machine.

Category | Industrial Mixers |

High-speed industrial mixer for powders

These high-speed industrial mixers are designed to quickly blend, condition, and mix large batches of products including powders, pharmaceuticals, refractory castables, spices and other types of products. They can also be engineered to process hazardous and non-hazardous dust and industrial bi-products for disposal that meets today’s stringent environmental laws and restrictions.

Category | Bulk Bag Unloaders | Industrial Mixers | Small Vibratory Feeders |

This batching system was custom designed for 7 types of carbon black. They are all simultaneously fed into individual weigh hoppers. Small vibratory feeders meter the carbon black into 16 cubic feet, net weigh hoppers supplied with air-operated, fast acting roller slide gates.

Upon discharge, an air-powered industrial vibrator cleans the weigh hopper before the gate closes. The batch is then transferred by belt conveyor to a 16 cubic feet confirmation (check weigh) hopper, where the final weight is either accepted or rejected. Accepted batches go directly into an industrial mixer. If a batch is out of tolerance, it is rejected via a pantleg diverter into a portable storage container at floor level.

Upon discharge, an air-powered industrial vibrator cleans the weigh hopper before the gate closes. The batch is then transferred by belt conveyor to a 16 cubic feet confirmation (check weigh) hopper, where the final weight is either accepted or rejected. Accepted batches go directly into an industrial mixer. If a batch is out of tolerance, it is rejected via a pantleg diverter into a portable storage container at floor level.

Category | Bulk Bag Unloaders | Industrial Mixers |

Bulk bag unloading station and five-ingredient net weigh hopper

This powder blending and batching system was built for a manufacturer of engineered refractory products. They required an automated system to blend and batch seven dry ingredients.

The customer had five existing exterior storage hoppers which where retrofitted with new screw conveyors. The screw conveyors transported their product into a five-ingredient net weigh hopper. In addition to the materials fed into the hopper, there are two loss-of-weight bulk bag unloading stations which are able to simultaneously dispense precise amounts of material. Both the net weigh hopper and the loss-of-weight unloading stations feed onto a collection conveyor for transport to the existing industrial mixer.

Category | Bulk Bag Unloaders | Industrial Mixers | Small Vibratory Feeders |

Powder blending of concrete products by weight

This powder blending system is used to mix dry ingredients by weight to create concrete products. Once the ingredients are unloaded into the system, they are conveyed to an industrial mixer.

The equipment consists of a big bag unloader on tank-type load cells, a 50 pound bag dump station with self-contained dust collector, a twin motor vibratory 2-speed feeder with an inclined corrugated side wall, and a cleated belt conveyor. All equipment was designed for dust-tight operation.

Category | Industrial Mixers |

These types of industrial mixers are designed for abrasive and difficult to mix minerals. Mixing capacities range from eight cubic feet to six cubic yards.

Category | Industrial Mixers |

In the production of cement, there is a waste product collected from the hot gas discharge of a kiln. This waste material is commonly called Cement Kiln Dust, or CKD. Because there are limited markets for CKD, it is usually sent to surface impoundments or landfills for disposal.

This extremely fine, dry, and dusty powder is typically conditioned by adding water to the solids before loading into trucks for disposal. CKD can be difficult to get a consistent moisture content to ensure that all the dry solids are wetted to a dustless mixture.