This automatic bagging machine fills plastic bags with different blends of bird seed. After filling, the bags are automatically sealed, palletized, and boxed. The video shows 20, 30, and 40 lb. bags of bird seed being filled and sealed.

NEED HELP FAST? We have over 40 years' experience with Bulk Material Handling, Packaging, and Processing. (979) 217-1480 GET A QUOTE

NEED HELP FAST? (979) 217-1480 GET A QUOTE

Explore our case studies detailing how our bulk processing equipment has helped businesses streamline their operations and boost efficiency.

Category | Automatic Bagging Machines | Open Mouth Bagging Machines |

This automatic bagging machine fills plastic bags with different blends of bird seed. After filling, the bags are automatically sealed, palletized, and boxed. The video shows 20, 30, and 40 lb. bags of bird seed being filled and sealed.

Category | Automatic Bagging Machines | Bag Handling Conveyors | High Speed Robotic Palletizers | Valve Bag Fillers |

These valve bag filling machines are used to fill 50 Lb. paper valve bags with different types of high-quality silica sand. After filling, bags are conveyed to an automatic palletizer that stacks the bags on a pallet.

This type of silica sand is a high-quality round and sub-round silica sand with mesh sizes ranging between 8×16 and 100. It has many uses including:

Category | Bulk Processing Equipment | Large Vibratory Feeders |

This automatic bag opener and emptying system can slice and slit open 20-110 pound bags and empty the contents into downstream conveyors or processing equipment. It opens various bag types including multiply / multiwall paper bags, polywoven bags, and burlap bags containing but not limited to coffee, flour, grains, nuts, sugar, spices, beans, seeds, salt, oats, corn, cocoa, peanuts, mustard, peppercorn, whey powder, corn flour (starch), chemical powders and granules, as well as active pharmaceutical ingredients (APIs).

Category | Open Mouth Bagging Machines |

This system precisely unloads free-flowing seeds, feed, corn, and more from a Buckhorn CenterFlow seed pro box into open mouth bags using an open mouth bag filler. The system can also be used to bag other free-flowing agricultural products like bird seed, wheat seed, deer corn, animal feed, fertilizer, pellets, and more.

Category | Food Seasoning and Coating |

The recent installation of an electrostatic coating system on a popped chip manufacturing line again demonstrated several benefits to the customer. The customer has different flavorings they apply to the popped chips which makes change over a challenge. The simplicity of the new system made operation and maintenance much simpler and quicker than the previous system.

Category | Automatic Bagging Machines |

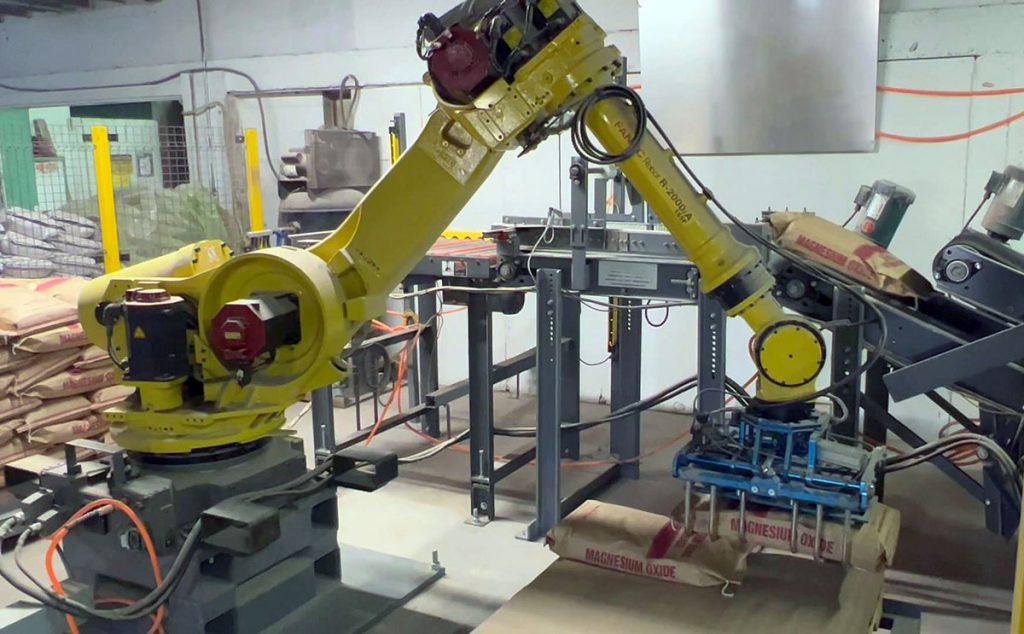

A robotic valve bag placer automatically picks up a bag and places it onto the spout of a valve bag filling machine. One robotic arm can place around 12 bags per minute depending on the fill rate of the machine and system.

Category | Automatic Bagging Machines | Bag Handling Conveyors | Bulk Processing Equipment | High Speed Robotic Palletizers |

One of our manufacturers recently designed and implemented an automatic depalletizer and bag dump station for a customer in the chemical industry. The system involves a robot depalletizer that unstacks 50 lb. bags of chemical powders from a shipping pallet located to the left and right side of the robot. The bags are picked up 3 at a time and placed 1 at a time on a conveyor that transports them to an inclined belt conveyor that discharges them into automatic bag dump station. In this article, we’ll provide an overview of the system, explain how the robot depalletizer system works using a vision system, and outline the features and benefits of the system.

Category | Automatic Bagging Machines | Bag Handling Conveyors | Bulk Bag Unloaders | Bulk Processing Equipment | High Speed Robotic Palletizers | Industrial Mixers | Open Mouth Bagging Machines | Small Bag Fillers | Small Vibratory Feeders |

Automate your candy and chocolate production lines and processes!

New or existing candy and chocolate production lines can be fully automated and equipped with control systems on all processing units.

Category | Automatic Bagging Machines | Bag Handling Conveyors | High Speed Robotic Palletizers | Open Mouth Bagging Machines |

Pallets stacked by 2 robotic palletizers are automatically conveyed into one stretch wrapper. A hood is also applied during wrapping.

Category | Bag Sewing Machines and Heat Sealers | Open Mouth Bagging Machines |

This fertilizer bagging system is used to fill poly bags with granular, free-flowing fertilizer. It includes a specially designed discharge stand and stainless steel hopper for Buckhorn CenterFlow seed boxes, a stainless steel digital gross weigh bagging scale with pneumatic bag clamp, a stainless steel mesh belt bag closing conveyor, and a hot air bag sealer.

The same type of system could be used to bag other types of free-flowing products like animal feed, plastic pellets, grains, seeds, wood pellets, and more. Multiple bag filling recipes are stored and easily swapped out via the digital scale controller.

Category | Bag Handling Conveyors | Bag Sewing Machines and Heat Sealers | Open Mouth Bagging Machines |

The Grain and Corn Bagging System combines product storage, filling, and bag closing into one system. Efficiently fill and close 30-50 lb. paper and poly-woven open mouth style bags.

The Grain and Corn Bagging System combines product storage, filling, and bag closing into one system. Efficiently fill and close 30-50 lb. paper and poly-woven open mouth style bags.

The system has been engineered for bagging deer corn (whole corn), feed, seed, and other grains. The manual, or mechanical, bagging option includes automatic weighing. The system is upgradeable to a higher packaging speed with the addition of a high-speed bag sewing system to quickly close the bags. Additional options are available including hand held bag sewing machines, bag flattening conveyors, and bag stacking systems.

Category | High Speed Robotic Palletizers |

Automating the stacking, or palletizing, of bags at the end of a packaging line with a used robotic palletizer can provide a fast return on investment. Robotic palletizers can be oriented in any direction to accept bag inflow from a new or existing bagging system. They minimize the risk of repetitive injuries caused by stacking heavy bags on shipping pallets, while simultaneously reducing labor and staffing requirements.

Automating the stacking, or palletizing, of bags at the end of a packaging line with a used robotic palletizer can provide a fast return on investment. Robotic palletizers can be oriented in any direction to accept bag inflow from a new or existing bagging system. They minimize the risk of repetitive injuries caused by stacking heavy bags on shipping pallets, while simultaneously reducing labor and staffing requirements.

Category | Bulk Processing Equipment | Intermediate Bulk Containers or IBCs |

This automated IBC discharge system empties battery powder from one intermediate bulk container into an empty IBC under a nitrogen purge. This type of powder handling system is used during the battery manufacturing process.

Category | Automatic Bagging Machines | High Speed Robotic Palletizers | Open Mouth Bagging Machines |

View of Bagging Machine and High-Speed Bag Closer in an Automated Packaging System

Rice producers face several challenges when it comes to bagging and packaging their product. Manual bagging processes can be time-consuming, labor-intensive, and prone to errors. To overcome these challenges, a USA-based rice producer sought an automated packaging system that could increase production efficiency, reduce labor costs, and improve bagging accuracy. In this case study, we’ll examine how the company successfully implemented the system, resulting in significant time and cost savings.