These valve bag filling machines are used to fill 50 Lb. paper valve bags with different types of high-quality silica sand. After filling, bags are conveyed to an automatic palletizer that stacks the bags on a pallet.

This type of silica sand is a high-quality round and sub-round silica sand with mesh sizes ranging between 8×16 and 100. It has many uses including:

- turf sand used for infill to protect artificial turf and increase its life expectancy

- roofing sand for specialty roofing tiles, flooring titles, and colored grout

- building and industrial sands as an ideal base for construction, concrete, bricks, foundry, and flooring

- water filtration sand used in wells, filters, and other water fixtures

- glass sand for large quantity glass production

- oil and gas hydraulic fracturing sand

Process Description

Sandstone is mined, crushed, washed, and screened or sized before being conveyed to a bulk storage silo.

The silica sand is withdrawn from the bulk storage silo using a belt conveyor that conveys the sand to a packaging bin located above the valve bag filling machines. The bagging system consists of 2 air packers that blow, or push, a set target weight of fluidized sand into a 50 pound paper valve bag using low pressure air. Sand can also be packaged into poly or plastic valve bags as well.

Watch a Video:

Valve Bag Filling Machines

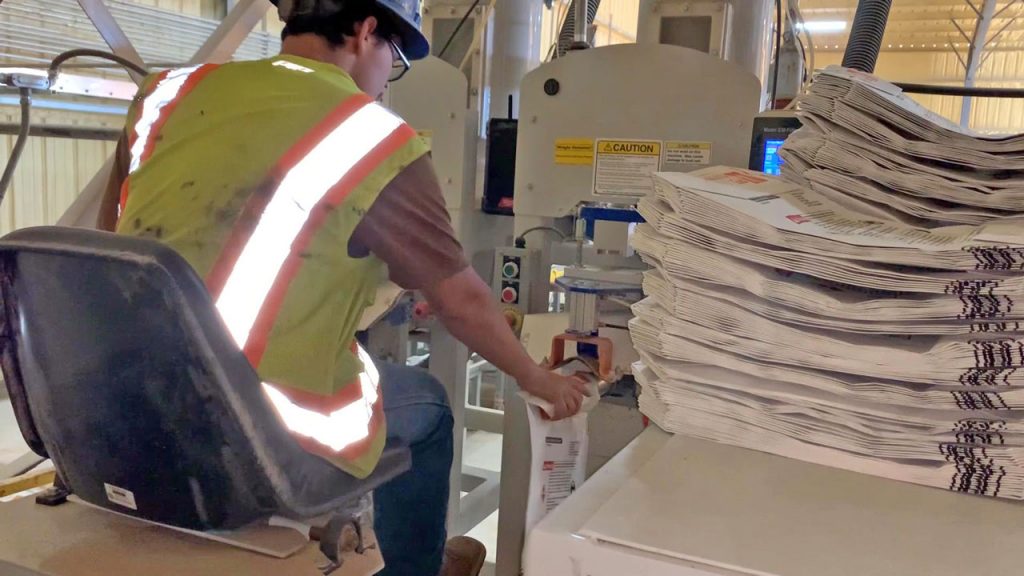

An operator in an elevated chair within the bag filling system picks up empty paper valve bags and places them on one of the 2 bag spouts. Each valve bag filling machine automatically starts the fill process and blows the sand from the air chamber into a bag until a set target weight has been reached. Then, the bag discharge chair automatically “tips and drops” the bags onto a heavy-duty wire mesh discharge conveyor.

The bags are conveyed over a check weighing conveyor that checks to see if each bag weight is out-of-spec, or underweight. Rejected bags are removed from the system and the in-spec bags travel toward the automatic palletizer. Next, bags are conveyed past a code printer, that prints a lot code and date on each bag as it goes by.

Automatic Palletizer

Bags travel through a series of conveyors that prepare them for palletizing: squaring conveyor, accumulation conveyor, and robot pick conveyor.

An automatic palletizer, or robot, with a bag tool picks up each bag and stacks them in a set stack pattern, or recipe. An automatic pallet dispenser conveys empty pallets into the bag stack zone as needed. After each pallet has been filled, they are conveyed to the end of the packaging line where an operator with a fork truck retrieves the full pallets and takes them to a stand-alone / remote pallet wrapper. After wrapping the pallets, they are moved to storage or shipping.

Additional Opportunities for Automation

Further automation for this type of system could be achieved by adding an automatic bag placing robot. We also offer a bag placing robot that can place empty bags and then palletize the filled bags immediately after, thus removing a large part of the conveying system, operators, and saving valuable floor space.

Ask a question -or- get a price quote!

Call: (979) 217-1480