« Equipment and Systems

-

- Open Mouth Baggers

- Valve Bag Filling Machines

- Bulk Bag Filling Machines

- Bulk Bag Unloaders

- Bag Sewing Machines

- Bag Sealing Equipment

- Bag Handling Conveyors

- Manual Palletizing Systems

- Robotic Bag Palletizers

- Gantry Palletizer Systems

- Automated Pallet Wrappers

- Automatic Bagging

Machines & Systems - IBC Blending

- Stainless Steel Intermediate Bulk Containers

Robotic Bag Palletizers

Ready for a palletizing system upgrade?

Automating the palletizing of bags using a robotic bag palletizer can provide one of the fastest returns on investment!

These systems use a palletizing robot arm to automatically stack bags, boxes, buckets, and more on pallets for shipping or storage. They can operate 24/7, effectively eliminating the need for a team of operators at the end of a packaging line stacking heavy bags on pallets. They are space saving solutions that can be oriented in any direction to accept bag inflow from a new or existing bagging system.

What types of bagging systems are good candidates for a robotic bag palletizer?

Typically, a bagging system that handles the fewest number of products, uses one type of bag, and requires at least 3,000 bags filled per 8 hour day is a good candidate for a robotic bag palletizer. Conversely, bagging systems with multiple products being packaged into paper and plastic bags could require more of a customized solution.

NEW! Do you have different types of bags in your bagging line -or- do you have floppy bags filled loosely with products such as animal feeds, grains, seeds, fertilizers, minerals, aggregate, sand, rocks, potatoes, onions, and more? Check out the Gantry Palletizers Systems page for affordable alternatives to traditional robotic arm palletizers.

Ask a question or get an exact price quote to fit your project’s requirements!

Watch a Video:

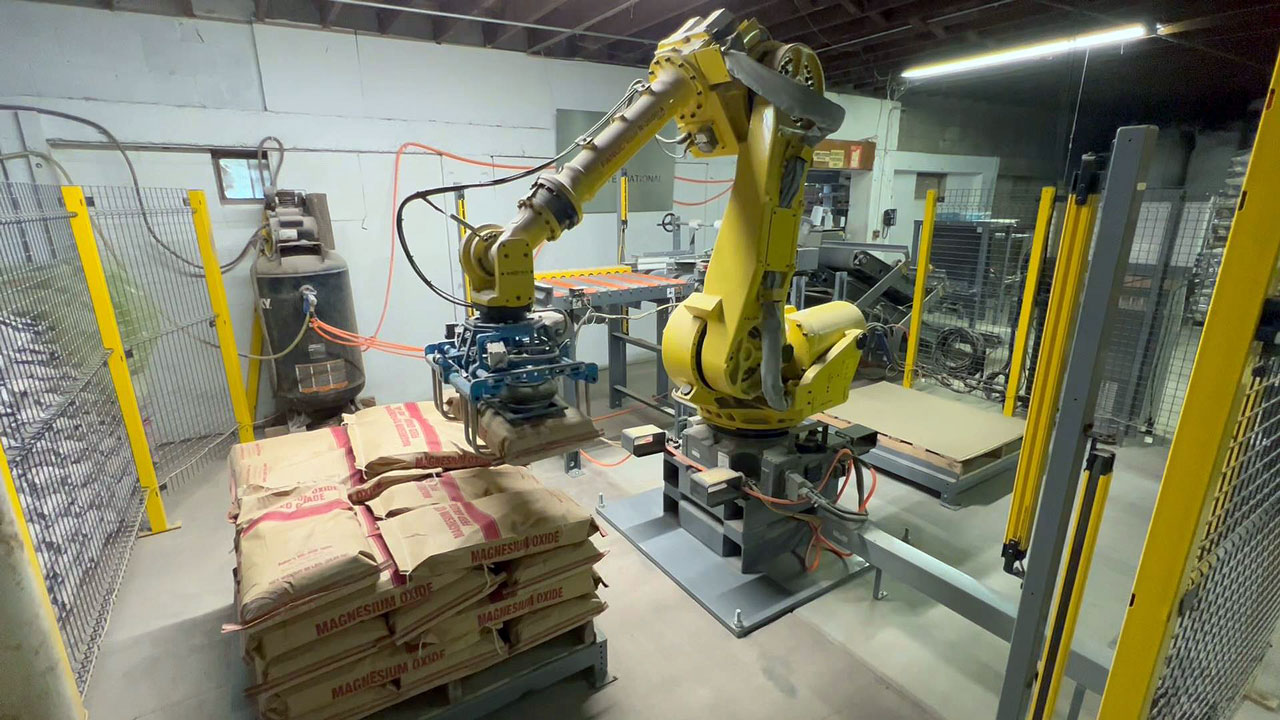

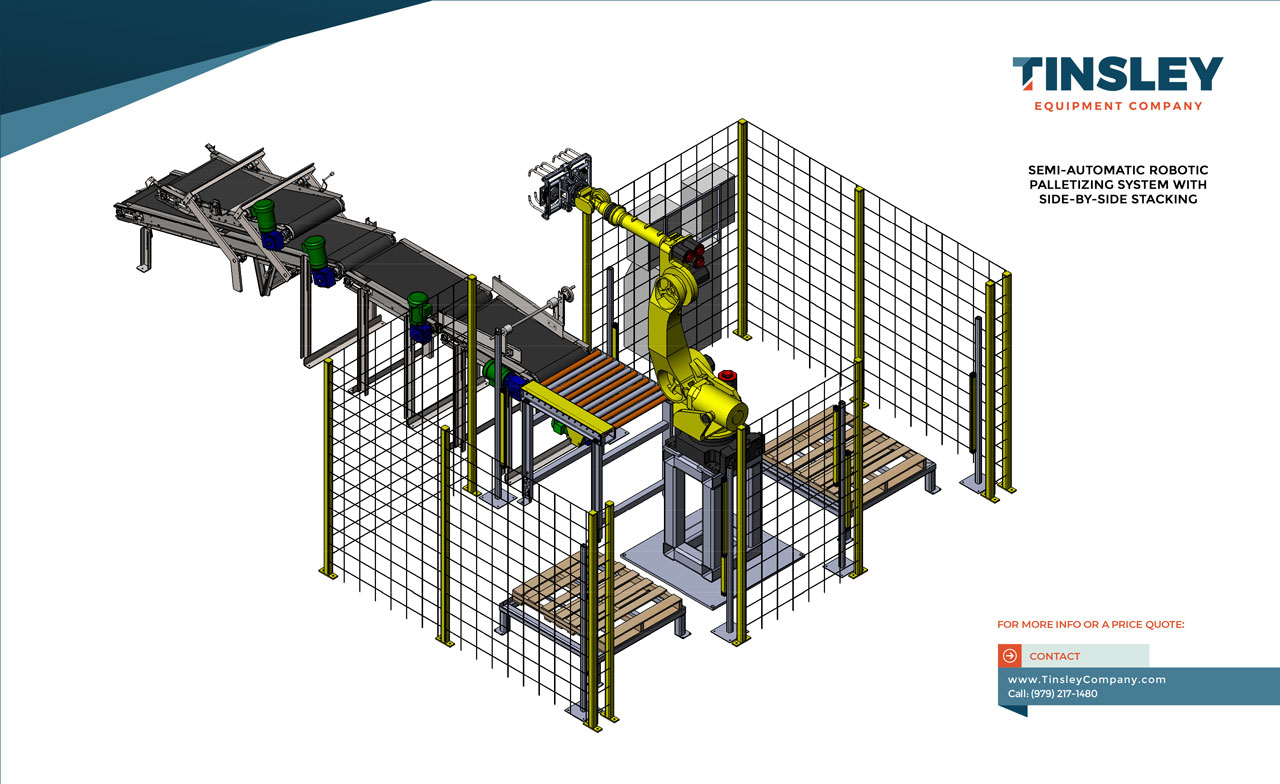

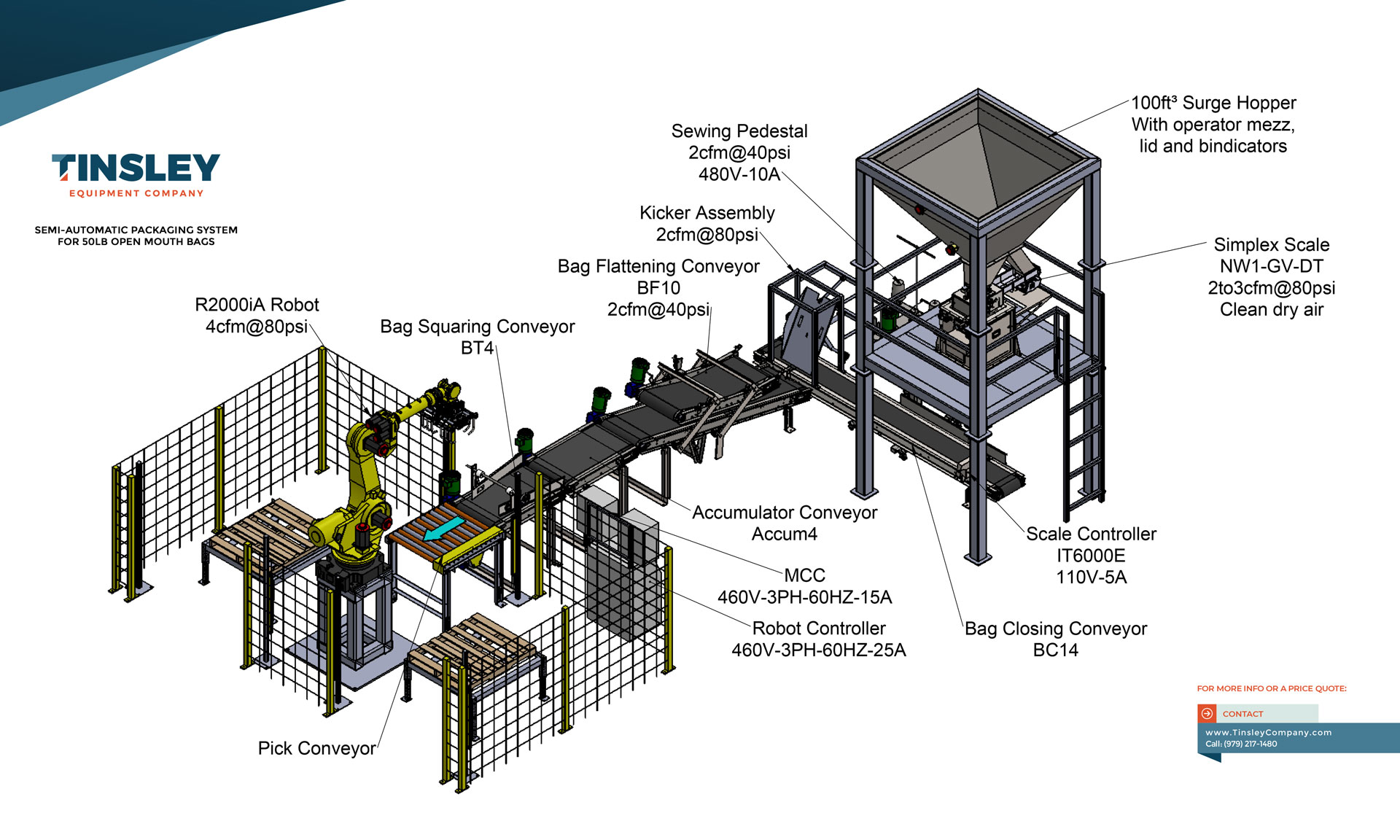

Single or Dual Stack Robotic Bag Palletizers

This type of palletizing system uses a Fanuc or Kawasaki palletizing robot in a single or dual stacking configuration. They are recommended for bagging lines filling 12 bags per minute or less. In this type of system an operator is still required to load empty pallets into the bag stack zone for the palletizing robot arm to stack bags upon. Safety fences surround the end of the bagging line, as well as the robot to ensure that the robot is not active in the zone where a forklift operator retrieves a filled pallet.

Process Description:

Empty pallets with slip sheets are placed manually by an operator in a designated place on the floor to the left or right of the palletizing robot arm. Filled bags are conveyed through a flattening conveyor, accumulation conveyor, squaring conveyor, and finally to a pick conveyor at the end of the bagging line. The palletizing robot arm picks up the bags and uniformly stacks them on the empty pallet. Once the pallet is full, a forklift operator will drive into the cage to retrieve the full pallet. If the system allows for dual stacking, the robot will start to stack bags on the empty pallet to the left or right of the robot, while the forklift operator safely retrieves the full pallet. Full pallets are then taken to an automated pallet wrapper to secure the bags into place on the pallet. Then, the pallets are transported to shipping or storage.

- Palletize up to 12 bags per minute or less

- Single 6-axis palletizing robot arm and mounting base (multiple types of arms to choose from)

- Touch-screen controls allows anyone to easily operate the robot with very little training

- Small footprint allows for installation in existing plant layouts

- Available in single or dual pallet stacking configurations

- Industrial strength end-of-arm tooling for multiple bag sizes and weights

- Lifting capacity weight ranges up to 110 lbs.

- Programmable pallet stack patterns with multiple pick points

- Wire mesh safety fence with locking access door

- New or used robots available

- Multiple robotic arms to choose from with end of arm tooling for bag, cases, boxes, pails, and buckets

- Bag vacuum

- Fork-style

- Bag clamp - single or multiple pick

- Case grip

- Robot protection and control packages for corrosive and high-temperature palletizing environments

- Multiple 3 phase power options

- Industrial bag handling conveyors to fit new or existing bagging plant layouts

Images

Click a thumbnail below to view larger images of semi-automatic and fully automatic robotic bag palletizers and systems.

- Click for larger image

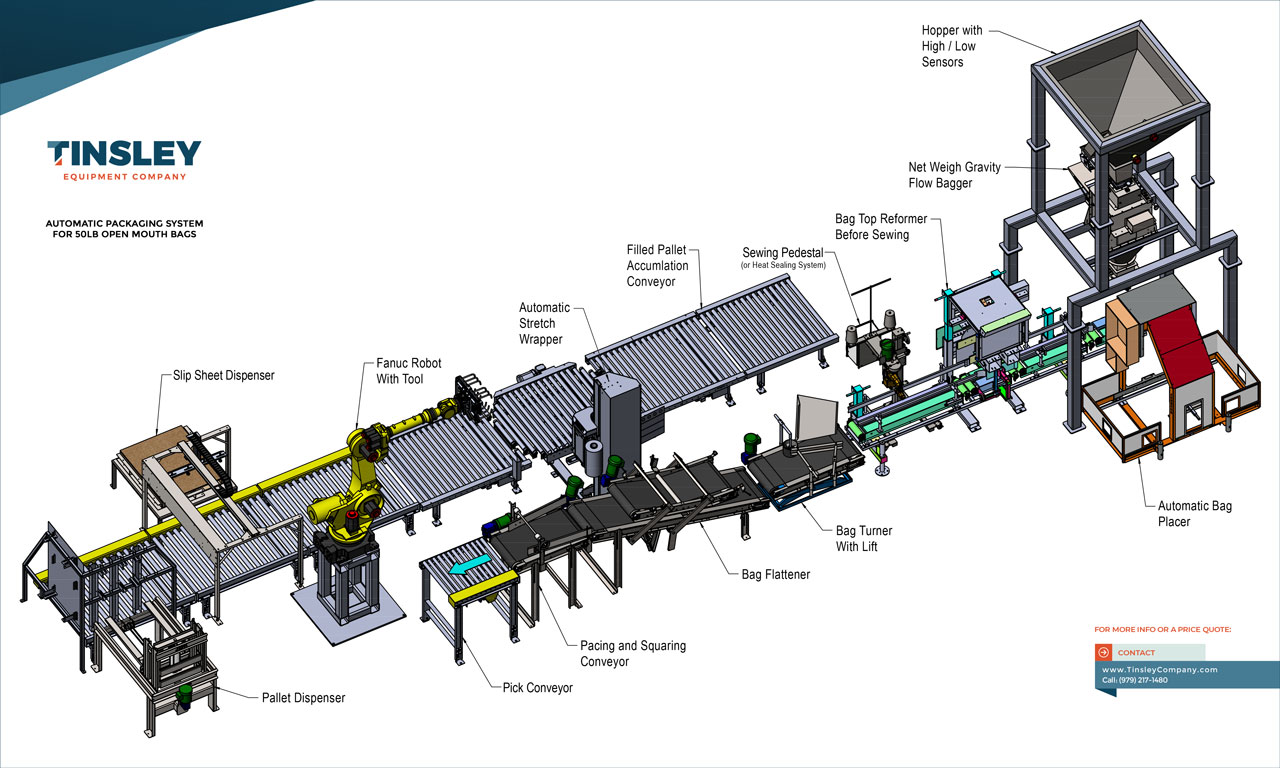

- Fully automated bagging system with robot bag stacker

Watch a Video:

Need help fast? Use our Express Contact Form

Call: (979) 217-1480

Fully Automatic Palletizing Systems

These types of systems also use a Fanuc or Kawasaki palletizing robot arm, but include additional equipment to fully automate end-of-line palletizing. This type of automatic system is for bagging operations filling 15 bags or more per minute.

Process Description:

An automatic pallet dispenser pushes an empty pallet onto the robot stacking conveyor. The empty pallet is conveyed to an optional slip sheet applicator that places a slip sheet on top of the pallet. Next, the pallet with the slip sheet is conveyed into the bag stack zone. The palletizing robot arm with bag tool picks up filled bags from the pick conveyor and uniformly stacks them on the empty pallet. When the pallet is full, it is conveyed to an automated pallet wrapper that spins and wraps the bags to secure them into place. Then, the filled pallet is conveyed to the end of the line outside of the safety fence, where a fork truck operator retrieves the palletized bags for shipping or storage.

- Palletize up to 15 bags or more per minute

- 6-axis palletizing robot arm and mounting base (multiple arms to choose from)

- Fully automatic system can be incorporated into new or existing plant layouts

- Automatic pallet dispensers

- Automatic slip sheet dispensers

- Automated pallet wrappers

- Touch-screen controls allows anyone to easily operate the robot and palletizing equipment with very little training

- Available in single or dual stacking configurations

- In-feed and full pallet transfer conveyors

- Industrial strength end-of-arm tooling for multiple bag sizes and weights

- Lifting capacity weight ranges up to 110 lbs.

- Programmable pallet stack patterns with multiple pick points

- Wire mesh safety fence with locking access door

- New or used robots available

- Additional end-of-arm tooling for bags, cases, boxes, pails, buckets, and more:

- Bag vacuum

- Fork-style

- Bag clamp - single or multiple pick

- Case grip

- Multiple palletizing robot arms to choose from

- Robot protection and control packages for corrosive and high-temperature palletizing environments

- Multiple power options

- Industrial bag handling conveyors to fit new or existing bagging plant layouts

Images

Click a thumbnail below to view larger images of semi-automatic and fully automatic robotic bag palletizers and systems.

- Click for larger image

- Fully automated bagging system with robot bag stacker

Watch a Video:

Need help fast? Use our Express Contact Form

Call: (979) 217-1480