One or more operators can use manual palletizing equipment to stack open mouth bags and valve bags containing a variety of agricultural products such deer corn, cottonseed hulls, oats, alfalfa pellets / cubes, soybean meal, barley, dried molasses, and mixing / stock salts. They can also stack bags filled with industrial products such as chemical powders, cement, mortar, and pigments.

Process Description

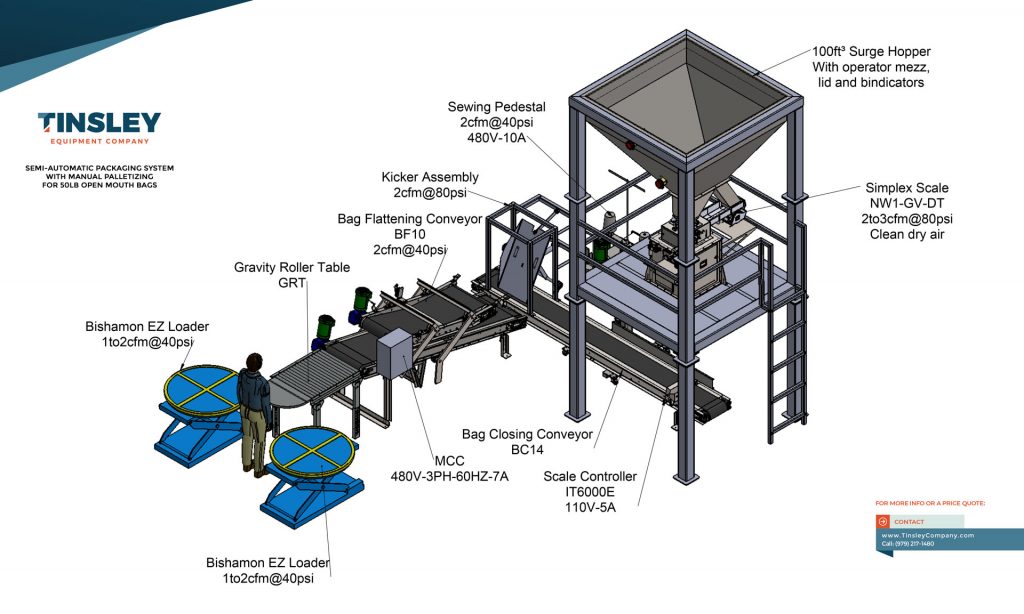

If you are filling open mouth bags, they first drop onto a closing conveyor, where the bags are closed using a bag sewing machine or heat band sealer.

If you are filling valve bags, they are automatically sealed and don’t require sewing. The valve bags simply “tip-and-drop” onto a wire mesh bag discharge conveyor.

50 Lb. bags of fertilizer “tip-and-drop” onto a wire mesh discharge conveyor

Next, if you need to turn, kick, or lay down bags, they move through a type of conveyor called a bag turner conveyor, or bag kicker. This orients the bags in the correct direction before they move through the next set of conveyors.

50 Lb. bag of nuts is knocked down and turned before moving through a bag flattener conveyor

Next, the bags are elevated using an incline conveyor. If you need to remove air from the bags, they will instead move through an incline bag flattener conveyor.

Bag incline conveyor lifts valve bags filled with sand up to a manual palletizing station

Then, the bags arrive at the gravity roller conveyor or table, where an operator picks up a bag and carries it over to the palletizing station.

Bag of magnesium silicate abrasive on a gravity roller conveyor or table

The shipping pallets can sit directly on the floor, or they can rest on top of an EZ pallet loader that automatically adjusts the height of the pallet to an ergonomic stacking height for the operators. When the pallets are full, a forklift operator will take the pallet away from the manual palletizing system and replace it with an empty pallet. If you have 2 palletizing stations, this will allow the operators to continue stacking bags while the forklift operator replaces the full pallet with an empty pallet.

Stacking 50 Lb. bags of abrasive sand in a manual palletizing system

Stacking bags of potassium chloride on an EZ pallet loader

Need pricing fast or have a question?

Use this express contact form! A Tinsley Equipment Company sales engineer will email you current pricing for all equipment and system components listed on this page usually within 24 hours or less. Need to speak with someone? Call: (979) 217-1480

* All fields are required.

Interested in an automatic palletizer?

Automating the palletizing of bags using a robot can provide the fastest return on investment. New robotic bag palletizers and reconditioned robots are available. Please contact us for more information.