Accurate dosing of seasonings into a tumbling drum, easy cleaning, reliability

Food production facilities use vibrating feeders (a.k.a. vibratory pan feeders -or- scarf feeders) for dispensing seasonings and spices directly onto the surface of food products as they tumble in a drum. This process is referred to as enrobing. The feeder can also meter seasonings precisely into a blended seasoning batch, or as an application of toppings and coatings in downstream processing equipment.

Seasoning Feeder Operation

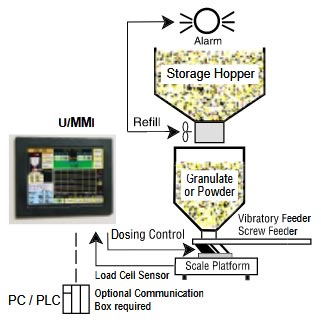

An electromagnetic vibratory drive imparts a controlled vibration to a metal surface commonly shaped like a pan or tube. To control the amount of seasoning used to coat food products, an adjustment is made to the conveying rate. The rate is controlled by adjusting the frequency and amplitude of the electromagnetic vibratory drive. This adjustment can be made manually by adjusting the speed setting from 1-1000 on the feeder controller or automatically, when connected to a control system. The dosage rate can either be volumetric, or by measuring the loss-in-weight, when configured as a Loss-In-Weight feeder. This precise control allows for extremely accurate dosing rates.

Vibrating feeder in a seasoning application system

This type of feeder is a great solution for dosing seasoning or flavorings into a tumbling drum, or enrobing drum, combined with our electrostatic seasoning system. This provides a uniform and consistent coating on chips, candy, nuts, croutons, popcorn, jerky, and other food products.

Cleaning and Maintenance

Cleaning is very easy because the feeder’s pan is constructed of a solid surface with no moving parts in contact with the seasoning. Covers can be easily removed allowing access to the conveying surface. Wipe down or wash down cleaning will quickly allow for proper cleaning procedures to be accomplished. This provides many years of reliable service. The feeder drive can be supplied for special environment conditions such as stainless steel construction, wash down, and explosion proof.