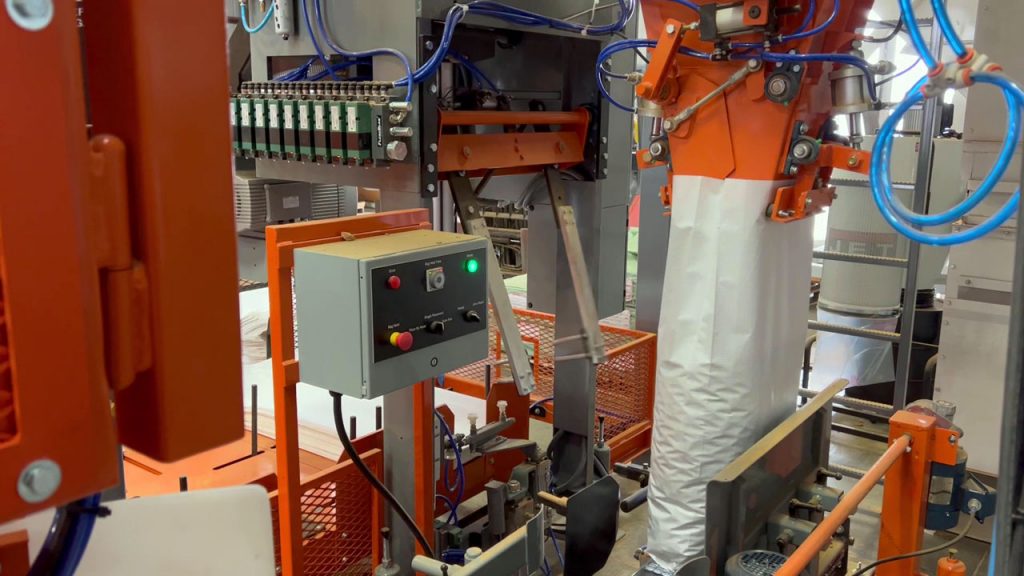

This automatic bagging machine fills plastic bags with different blends of bird seed. After filling, the bags are automatically sealed, palletized, and boxed. The video shows 20, 30, and 40 lb. bags of bird seed being filled and sealed.

NEED HELP FAST? We have over 40 years' experience with Bulk Material Handling, Packaging, and Processing. (979) 217-1480 GET A QUOTE

NEED HELP FAST? (979) 217-1480 GET A QUOTE

Automatic bagging machines and equipment greatly increase efficiency, bag filling capabilities, and palletizing rates. Almost any type of auto bagger machine and system can be designed for one or more operators using an existing packaging line or plant footprint. We have over 40 years' experience with automatic bagging machine and systems and can custom design a solution to meet your budget and processing requirements.

The first level of automation would be to add a bag tip and drop component to a valve bag filler machine. Then, make the system more automatic by adding a bag placer that automatically places an empty bag on the bag fill spout. Next, add a machine that includes a single or dual filling hopper that simultaneously fills while a bag or bags are being filled. The final level of automation would be to add a robot bag palletizer at the end of the line.

Ask a question or Get a Price Quote. Use our Express Contact Form or call: (979) 217-1480

Category | Automatic Bagging Machines | Open Mouth Bagging Machines |

This automatic bagging machine fills plastic bags with different blends of bird seed. After filling, the bags are automatically sealed, palletized, and boxed. The video shows 20, 30, and 40 lb. bags of bird seed being filled and sealed.

Category | Automatic Bagging Machines | Bag Handling Conveyors | High Speed Robotic Palletizers | Valve Bag Fillers |

These valve bag filling machines are used to fill 50 Lb. paper valve bags with different types of high-quality silica sand. After filling, bags are conveyed to an automatic palletizer that stacks the bags on a pallet.

This type of silica sand is a high-quality round and sub-round silica sand with mesh sizes ranging between 8×16 and 100. It has many uses including:

Category | Automatic Bagging Machines |

A robotic valve bag placer automatically picks up a bag and places it onto the spout of a valve bag filling machine. One robotic arm can place around 12 bags per minute depending on the fill rate of the machine and system.

Category | Automatic Bagging Machines | Bag Handling Conveyors | Bulk Processing Equipment | High Speed Robotic Palletizers |

One of our manufacturers recently designed and implemented an automatic depalletizer and bag dump station for a customer in the chemical industry. The system involves a robot depalletizer that unstacks 50 lb. bags of chemical powders from a shipping pallet located to the left and right side of the robot. The bags are picked up 3 at a time and placed 1 at a time on a conveyor that transports them to an inclined belt conveyor that discharges them into automatic bag dump station. In this article, we’ll provide an overview of the system, explain how the robot depalletizer system works using a vision system, and outline the features and benefits of the system.

Category | Automatic Bagging Machines | Bag Handling Conveyors | Bulk Bag Unloaders | Bulk Processing Equipment | High Speed Robotic Palletizers | Industrial Mixers | Open Mouth Bagging Machines | Small Bag Fillers | Small Vibratory Feeders |

Automate your candy and chocolate production lines and processes!

New or existing candy and chocolate production lines can be fully automated and equipped with control systems on all processing units.

Category | Automatic Bagging Machines | Bag Handling Conveyors | High Speed Robotic Palletizers | Open Mouth Bagging Machines |

Pallets stacked by 2 robotic palletizers are automatically conveyed into one stretch wrapper. A hood is also applied during wrapping.

Category | Automatic Bagging Machines | High Speed Robotic Palletizers | Open Mouth Bagging Machines |

View of Bagging Machine and High-Speed Bag Closer in an Automated Packaging System

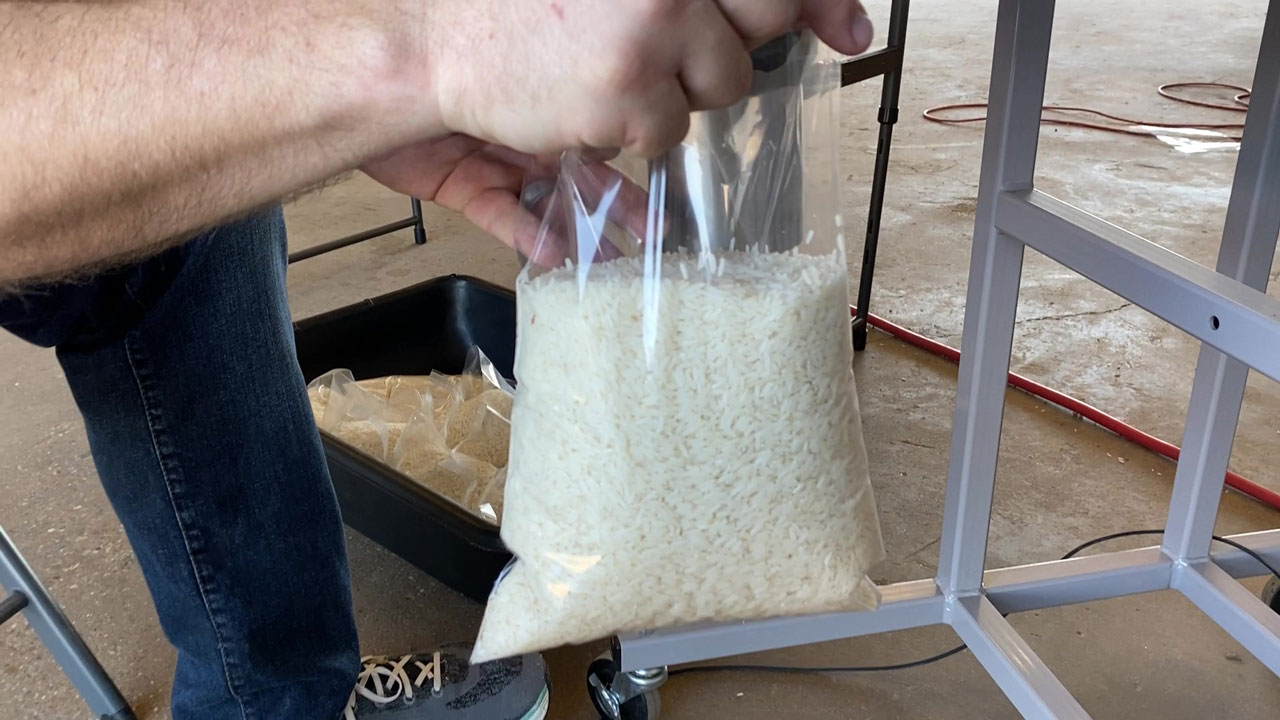

Rice producers face several challenges when it comes to bagging and packaging their product. Manual bagging processes can be time-consuming, labor-intensive, and prone to errors. To overcome these challenges, a USA-based rice producer sought an automated packaging system that could increase production efficiency, reduce labor costs, and improve bagging accuracy. In this case study, we’ll examine how the company successfully implemented the system, resulting in significant time and cost savings.

Category | Automatic Bagging Machines | Bulk Processing Equipment | Open Mouth Bagging Machines |

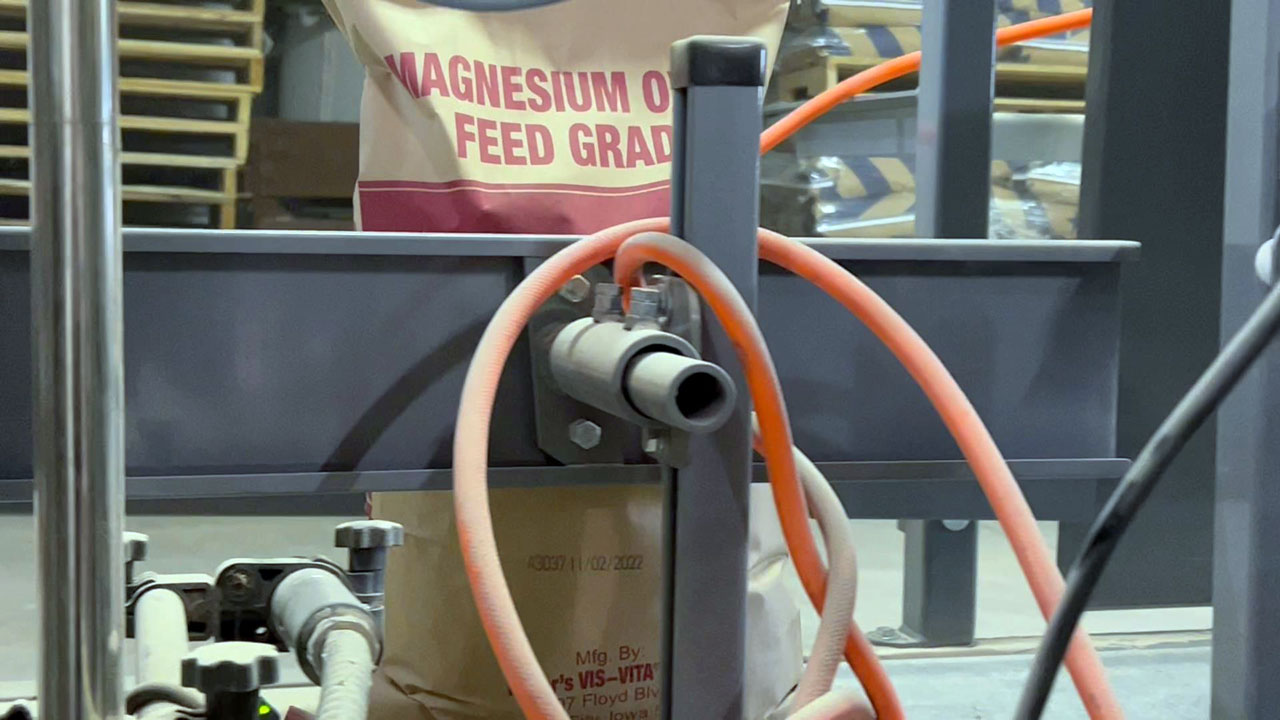

Lot / batch code and date printed on bottom part of bag after passing print head

This inkjet code printer was put to the test in an animal feed and minerals packaging line. Multi-wall open mouth paper bags, filled with animal feed are sewn shut. Then, they pass in front of the code printer on a conveyor before robotic palletizing. As each bag passes the code printer, a lot code and date are printed on the bottom part of the bag. Each of these unique codes helps to identify when the batch of product was produced and packaged.

Category | Automatic Bagging Machines | High Speed Robotic Palletizers |

The video below shows a pallet stacking robot stacking 50 lb. paper valve bags onto a pallet located on the floor per the programmed bag placement design. This robot was added to an existing bag filling system to reduce labor costs and increase automation.

Watch a Video:

Category | Automatic Bagging Machines | Small Bag Fillers |

This automated bagging machine uses a high-speed net weigher and bag placer to package free-flowing products into stand up pouches or doypacks.

Category | Automatic Bagging Machines | Open Mouth Bagging Machines |

The automatic bag placer machine picks up, hangs, and clamps an empty open mouth bag onto a bagger before product is discharged into a bag. Up to 20 bags per minute are possible and it works with both new / existing net weigh and gross weigh bagging scales. With this type of automation, one full-time operator can be removed from the bagging system.

Category | Automatic Bagging Machines | Bag Sewing Machines and Heat Sealers |

This machine automatically reforms or prepares the top of flat, pillow type open mouth bags and guides them into the infeed of a high-speed bag closer or sewing machine.

Bag moves through a bag top reformer before sewing

This type of automation can eliminate the need for an operator to manually guide a filled bag into a bag closing system. It can handle production rates up to 15 bags per minute and typically comes with an automatic bag placer.

Category | Automatic Bagging Machines | High Speed Robotic Palletizers |

Automatic pallet dispenser, slip sheet applicator, and robot stack zone conveyor (System 1)

When speed and bagging rate is important, automating the dispensing of pallets and slip sheets helps to reduce labor requirements for feeding shipping pallets into an automated palletizing system with a robot.

Category | Automatic Bagging Machines | Bagging Equipment by Product | Open Mouth Bagging Machines | Small Bag Fillers |

This commercial equipment is used for repackaging bulk dry goods stored in bulk bags, bins, totes, pro boxes, 40-50Lb bags, and more into small bags, pouches, and containers.

Examples of free-flowing bulk dry goods to repackage or re-bag would be food products such as rice, nuts, coffee beans, sprinkles, pasta, beans, candy, seeds, dog food, and cat food as well as products such as feed pellets, wood pellets, and plastic pellets.