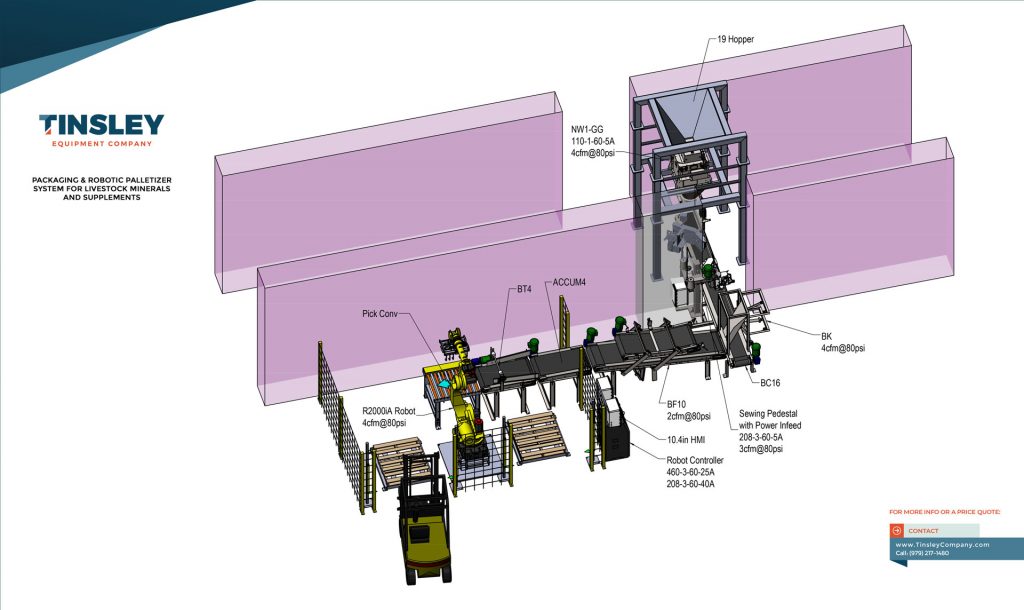

This packaging and palletizing line fills craft paper bags with 25, 40, or 50 lbs. of livestock minerals and supplements. It includes a hopper, net weigh bag filling machine, high-speed bag sewing system, and robotic palletizer with 2 bag stack zones. It replaced an existing bag filling and packaging line at the feed service company that has been in business since 1946.

Packaging and Palletizing Line Description

An operator places an empty craft paper bag on the open mouth bag filling machine’s spout. A pneumatic clamp closes to hold the bag in place. The operator releases a set target weight of livestock minerals and supplements into the bag. While the bag is filling, additional product flows freely by gravity from a supply hopper and into an internal weigh hopper located within the simplex net weighing bag scale. This alternating fill and dump cycle allows for a much faster fill rate compared to other types of bagging machines.

An operator in the background fills a bag while the operator in foreground guides bags into a high-speed bag sewing system

After filling, the clamp opens, and the filled bag drops onto the bag closing conveyor below. An operator manually reforms the top of the bag and guides it into the high-speed bag sewing machine.

After sewing, a bag kicker lays bags down before they go through a bag flattener conveyor

After sewing, the bag is conveyed to a bag kicker that lays the bag down so that it travels label side up onto an inclined bag flattener conveyor. Then, the bag arrives at an accumulation and robot pick conveyor.

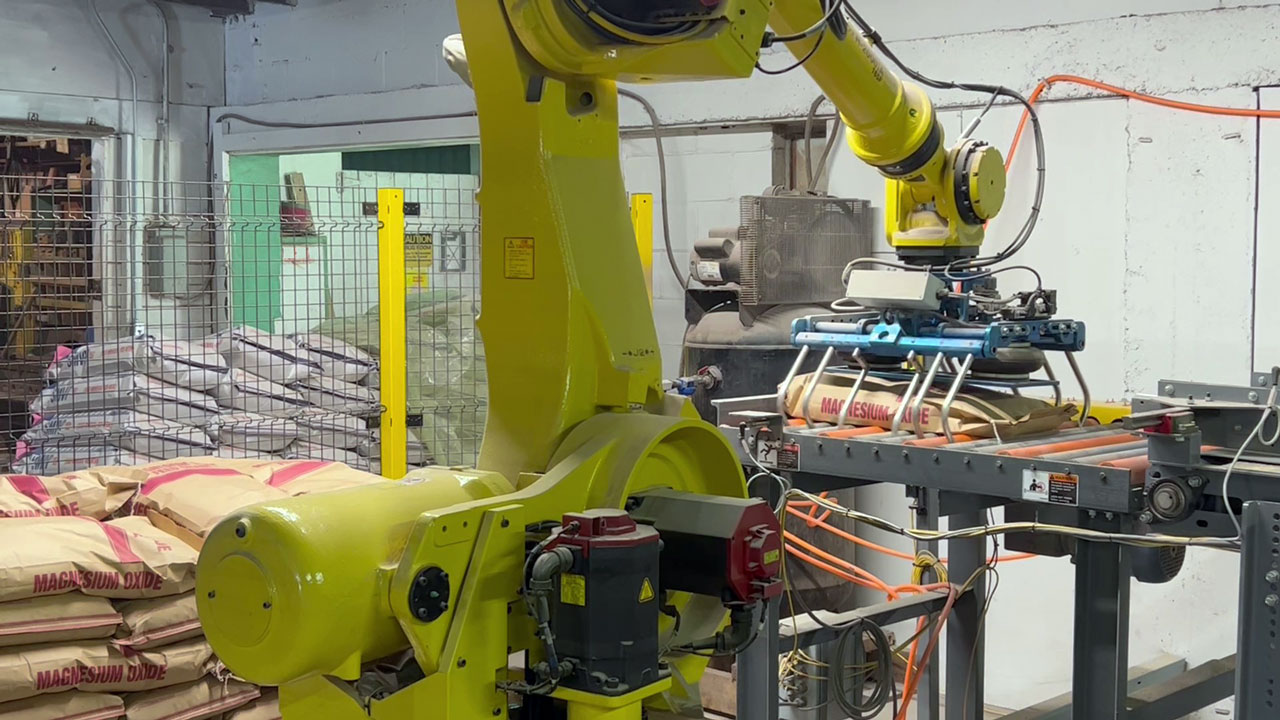

Palletizing robot picking up a bag from the robot pick conveyor

A Fanuc robotic arm with a bag tool picks up the bag and palletizes it on one of two pallets. Once one pallet has been filled, the palletizing robot automatically starts to stack bags on the empty pallet. An operator retrieves fully stacked pallets from the bag stack zone for wrapping, shipping, or storage. He manually replaces it with an empty pallet and slip sheet.

Palletizing robot stacking bags on a pallet

Further automation could be achieved by adding an automatic bag placer, bag top reformer before sewing, automatic empty pallet / slip sheet dispenser, and automatic pallet wrapper.

Watch a Video

Ready for a Packaging and Palletizing Line Upgrade?

Ask a Question -or- Get a Price Quote!

Call: (979) 217-1480