Choose from different types of rice bagging equipment to package rice and other grains into small bags, pouches, larger 50 Lb. bags, and all the way up to 4,400 Lb. bulk bags. All bagging machines have an accuracy of +/- 0.5-1% of target weight and can operate at different fill rates depending on your packaging line requirements.

Rice bagging equipment fills small to very large bags with rice

This type of equipment fills bags and pouches with many different types of free-flowing agricultural products such as grains and seeds. This includes wheat, oats, millet, cornmeal, barley, quinoa, kasha, amaranth, jasmine rice, basmati rice, arborio rice, wild rice, brown rice, and white rice regular and long grain.

Click a link to jump to a section below:

- Automatic Rice Bagging Equipment (up to 24 bags per minute)

- Small Net Weigh Rice Bagging Equipment (up to 30+ small bags, pouches, and containers per minute)

- Entry-Level

Automatic Rice Bagging Equipment

(up to 24 bags/min)

Use a high-speed simplex, duplex, or triplex net weigh bagging scale to fill up to 24 bags per minute with 20-110 Lb. bags (9-50 Kg) of rice. The dry rice flows freely by gravity from a supply hopper into an internal weigh hopper. When a bag fill cycle starts, rice is discharged from the internal weigh hopper in the bagging machine, through a funnel spout, and into the bag below. While the bag is being filled, an internal weigh hopper is being refilled for the next fill cycle. A dust-tight bag clamp secures the bag to the clamp to the fill spout.

Net weigh bagging scales are the baggers of choice for high volume industrial rice packaging companies!

- Filling Rate: Up to 24 bags/min (slower rates are available…see Mechanical and Digital Gross Weigh Bagging Scales below)

- Bag Weight Range: 20-110 Lbs. (9-50 KG)

- Bag Types: Paper, plastic, poly-woven open mouth bags

- Requirements

- Control air: 80 PSI required at 1 CFM per bag fill cycle

- Electrical: 220 volt, 380 volt, 440 volt, or 575 volt / 3 phase / 60 cycle

- Dust collection: 600 CFM minimum

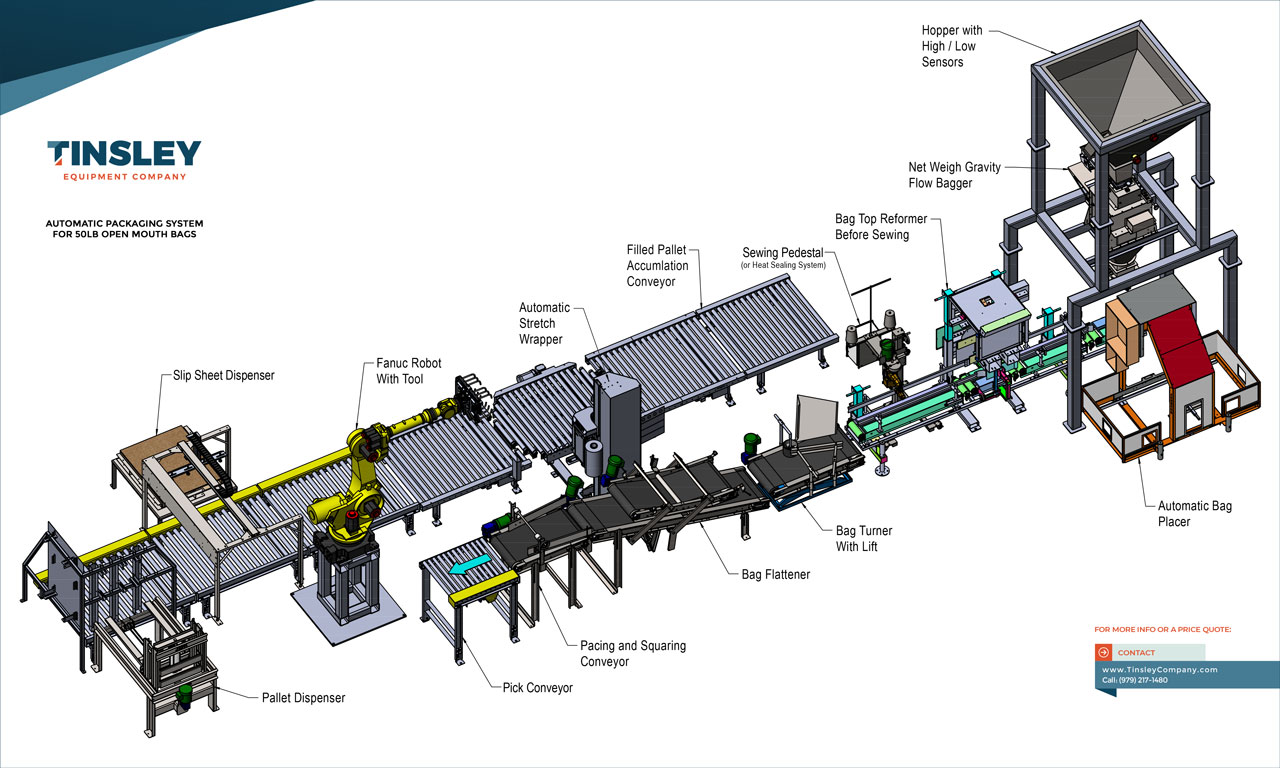

- Increase efficiency and reduce labor costs by adding: Automatic Bag Placer, Automatic Bag Top Reformer and High-Speed Sewing, Robotic Palletizer, Automatic Pallet & Slip Sheet Dispenser, Automatic Pallet Wrapper

Small Net Weigh Rice Bagging Equipment

(30+ small bags and pouches/min)

These small net weigh bagging scales fill bags and pouches with 1-25 Lbs. of dry, free-flowing rice. Use a simplex, duplex, or triplex configuration for high-speed rice packaging lines and operations. The standard small net weigh bagging scale includes a gravity gate, single vibrating pan feeder, and a weigh hopper that is suspended from a single load cell. A high-speed system includes a 100 cubic foot surge hopper, duplex net weigh bagging scale, and automatic bag placer. Stainless steel product contact surfaces or food-grade stainless steel construction is available, as well as dust tight spouts and enclosures.

- Filling Rates

- Simplex scale: 12 bags/min (720 bags/hr.)

- Duplex scale: 20+ bags/min (1,200 bags/hr.)

- Triplex scale: 30+ bags/min (1,800 bags/hr.)

- Bag / Pouch Weight Range: 1-25 Lbs. (0.45-2.26 KG)

- Bag / Pouch Types: pre-formed open mouth bags, stand up pouches, or doypacks constructed of paper, plastic, or poly-woven materials

- Increase efficiency and reduce labor costs by adding: Automatic Bag Placer, Bag & Pouch Sealers, Robotic Palletizer, Automatic Pallet & Slip Sheet Dispenser, Automatic Pallet Wrapper

Entry-Level Rice Bagging Equipment

Mechanical & Digital Gross Weigh Bagging Scales

(Fill 4-10 Larger 50 Lb. Bags per Minute)

These mechanical and digital gross weigh bagging scales fill 20-110 Lb. bags with free-flowing rice and other types of grains. No compressed air or electricity is required for the entry-level mechanical gross weigh bagging scale. Rice flows by gravity from a supply hopper into the bagging scale. When a fill cycle is initiated, rice flows through the gravity gate into a funnel spout and into the bag. The operator will then release the bag from the fill spout by lifting on the spring loaded bag grip lever on the mechanical bagging scale, or by depressing a button or foot pedal on the digital gross weigh bagging scales.

- Filling Rates: 4-10 bags/min

- Bag Weight Range: 10-110 Lbs. (4.53-50 KG)

- Bag Types: Paper, plastic, poly-woven open mouth bags

- Bag Sewing Systems: 4 bags/min sewing systems, high-speed bag closer systems, handheld bag sewing machines

Complete your entry-level packaging line with a manual palletizing system and semi-automatic pallet wrapper.

Ask a question or get a price quote!

Call: (979) 217-1480