The automatic bag placer machine picks up and spouts an empty open mouth bag onto a high-speed bagger before 50 lbs. of feed or grain is discharged into the bag. The bag placer is designed to work with most kraft paper bags and some plastic bags.

The automatic bag placer machine picks up and spouts an empty open mouth bag onto a high-speed bagger before 50 lbs. of feed or grain is discharged into the bag. The bag placer is designed to work with most kraft paper bags and some plastic bags.

How does a bag placer work?

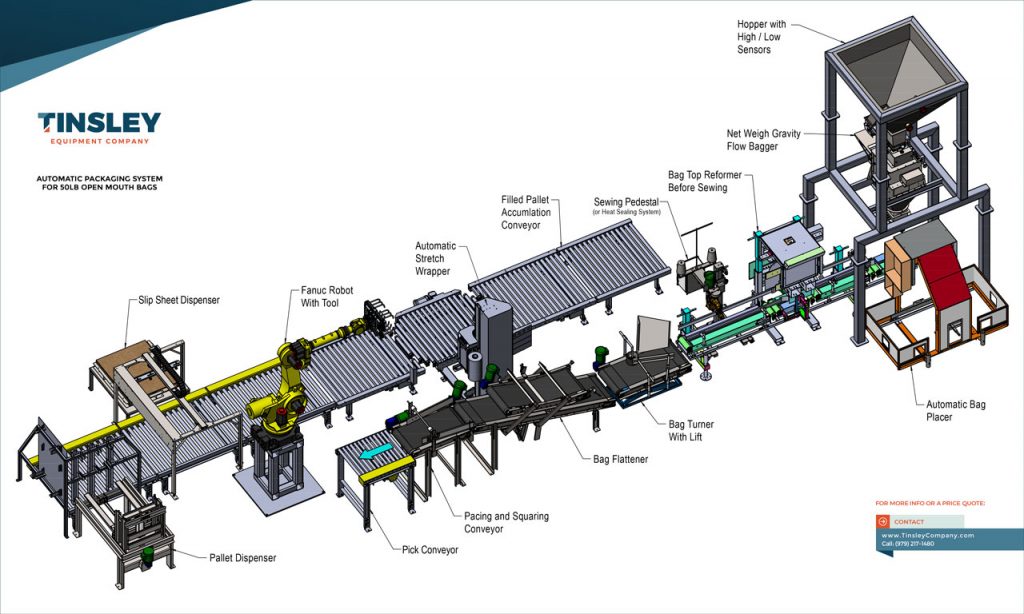

Empty open mouth bags are stacked onto an indexing magazine. The automatic bag placer machine picks up an empty bag using vacuum suction cups. The machine then pulls down on the under side of the bag and opens the mouth. Then, 2 arms spread open the bag and lift it, or hang it, onto the spout of the bag filler. Clamps on the bagging machine hold the bag in place while 50 lbs. of feed or grain is discharged into the bag. Once bag is filled, it drops gently onto the bag closing conveyor, where it moves through a bag top reformer and through a high-speed sewing machine. This type of open mouth bag placer, can place, or position, up to 15 bags per minute.

Watch a Video

Further automation of the feed and grain bagging system shown in the video could be achieved by adding an automatic bag top reformer before the sewing machine. A bag palletizing robot could also be added at the end of the packaging line.

Ready for a bagging system upgrade?

Speak with one of our sales engineers today and get a fast price quote.