Seasoning potato chips using an electrostatic seasoning system

Electrostatic seasoning systems can be retrofitted to existing food processing equipment and can result in 10-45% powder savings, while delivering excellent seasoning coverage.

With an average seasoning cost of $1-4 per pound (depending on formulation and supplier), return on investment in an electrostatic seasoning system can occur in 4 months or less.

Powder Savings Example: Seasoning Potato Chips

At the time this article was written, potatoes (at bulk purchase levels) are approximately 10 cents per pound and seasoning is between $1-4 per pound.

Seasoned potato chips

Traditional seasoning systems apply oil and seasonings to snack foods like potato chips using a vibratory or auger feeder to dispense seasoning into a rotating, flighted enrobing drum. Mechanical blending combined with residual oil from the chip frying process binds the seasoning to the potato chips. This type of process has been around for decades, but unfortunately results in uneven coating, over application, drop off, and seasoning loss due to aeration and residence time.

A novel solution to these issues has already been tried and tested in the automotive painting industry: Powder Coating.

This solution is now available for food seasoning systems resulting in the “Powder Coating of Foods.”

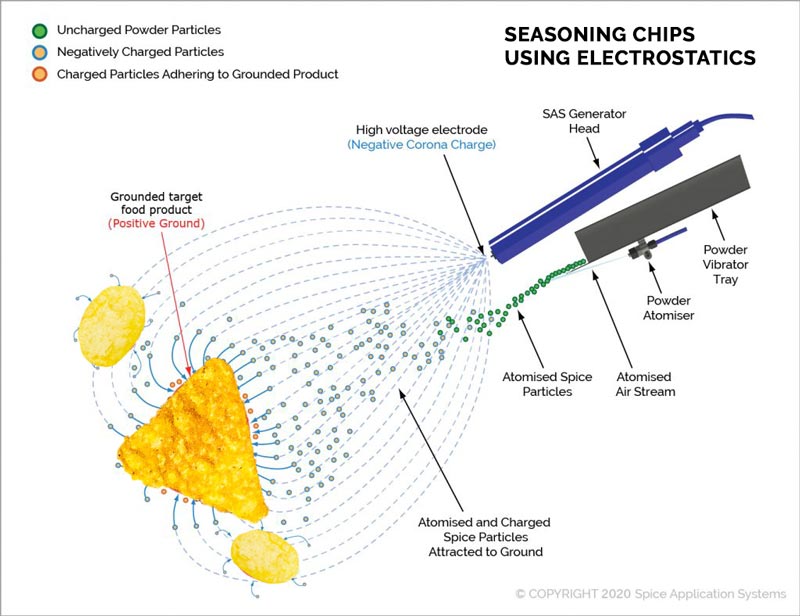

How does Electrostatic Seasoning work?

By grounding the rotating enrober drum, the potato chips become positively charged as they gently tumble through the drum. The seasoning (powder, oil, or slurry) is then fed or dosed into the drum and ionized (negatively charged) using a wand to create an ion cloud. The seasoning and coating adheres automatically to the positively charged potato chips – creating a true wraparound effect.

For the seasoning of potato chips, electrostatic seasoning can immediately reduce the amount of powder required by 15-30%.

Seasoning chips using electrostatics

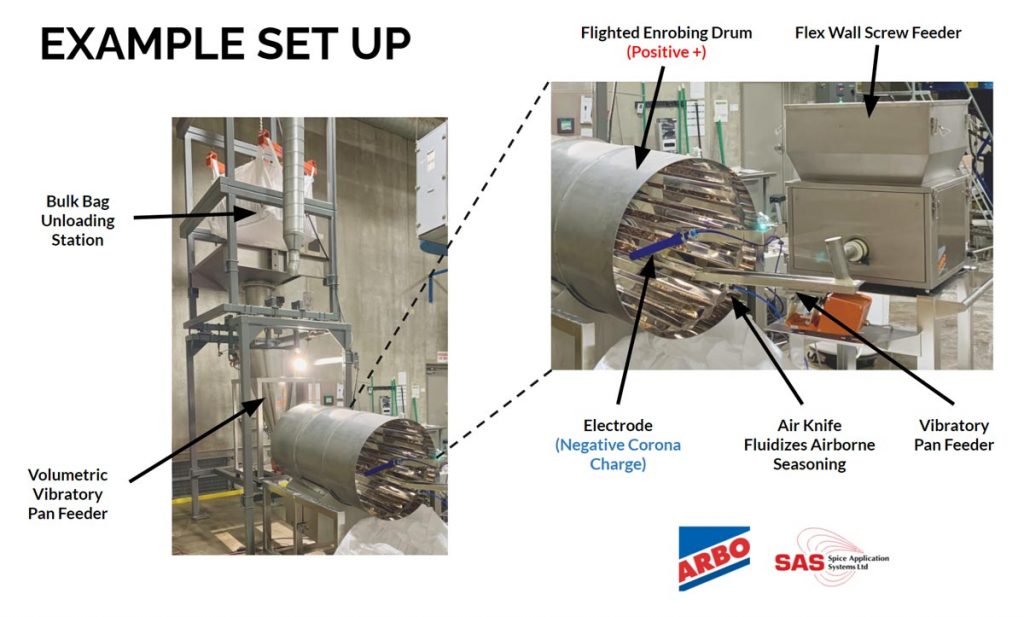

Can it be applied to existing enrobers or tumbling drums?

Yes! The electrostatic seasoning system is very compact and mounted on the outlet portion of an existing enrober or tumbling drum. This requires minimal alteration to existing equipment, which reduces costs and maximizes returns. The overall benefits are:

- consistent coating of food products

- reduced seasoning application and drop off

- reduced sanitation load, airborne seasonings, and seasoning on conveyors, packaging equipment, and facilities

- improved flavor consistency

- fast return on investment – usually in 4 weeks or less

Try before you buy! Product testing is available.

Electrostatic seasoning system example setup

Need pricing fast or have a question?

Use this express contact form! A Tinsley Equipment Company sales engineer will email you current pricing for all equipment and system components listed on this page usually within 24 hours or less. Need to speak with someone? Call: (979) 217-1480

* All fields are required.

Electrostatic seasoning system rotating drum, wand, and feeders

Learn more: