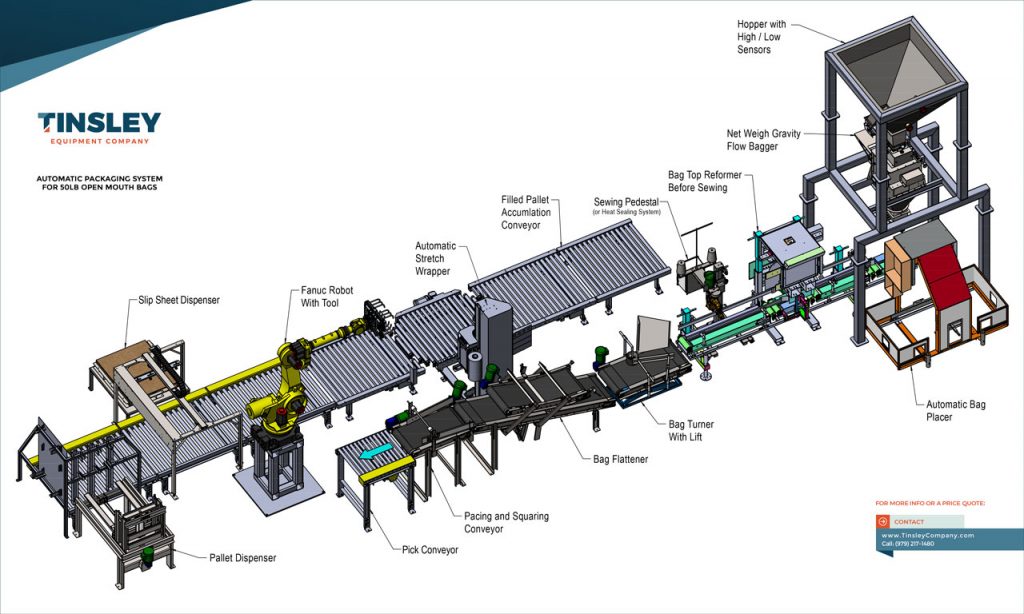

This automated packaging and palletizing system is designed to fill 20-110 lb. open mouth poly bags at a rate of 10 bags per minute or more. Free-flowing and dry bulk material flows from the 80 cu. ft. hopper into a net weigh gravity flow bagging scale that includes a vibrating feeder with a gravity gate. The feeder doses a set amount of product into the internal weigh hopper of the bagging scale.

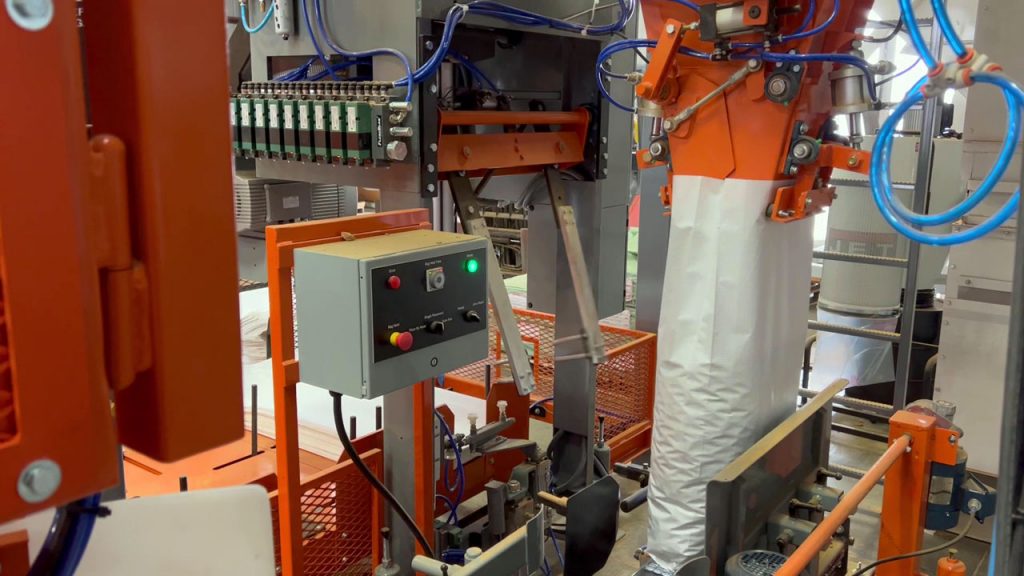

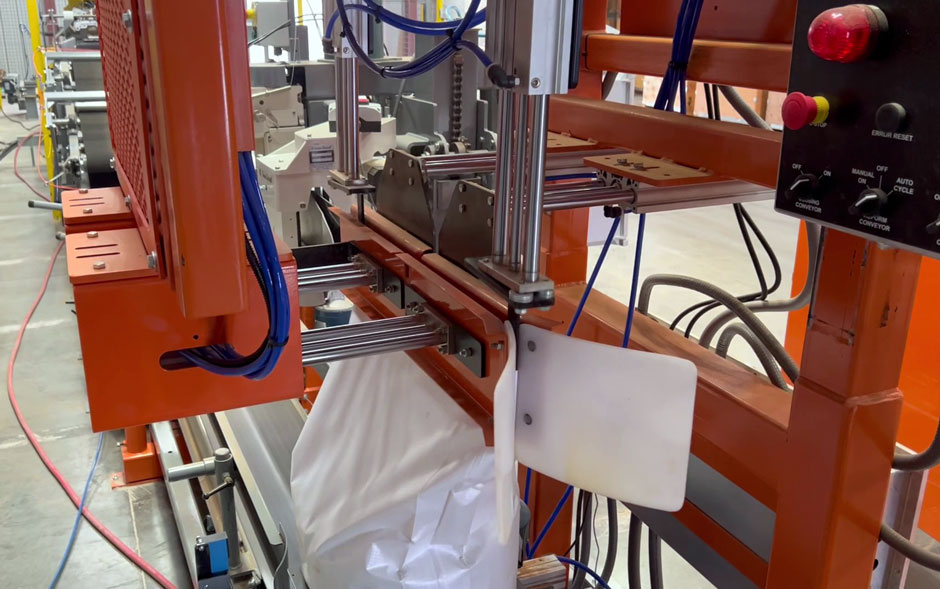

Poly bags are spouted onto the bagging scale using an automatic bag placer. After the bags reach a set target weight, they drop to the bag closing conveyor where they move through a automated bag top reformer that prepares the bags to be sewn shut.

After sewing, the bags move through a series of bag handling conveyors. They are are knocked down and turned. Then, they move through a bag flattener, a pacing / squaring conveyor, and onto a robot pick conveyor.

After sewing, the bags move through a series of bag handling conveyors. They are are knocked down and turned. Then, they move through a bag flattener, a pacing / squaring conveyor, and onto a robot pick conveyor.

50 lb. bag of nuts is knocked down before moving through a bag flattener conveyor

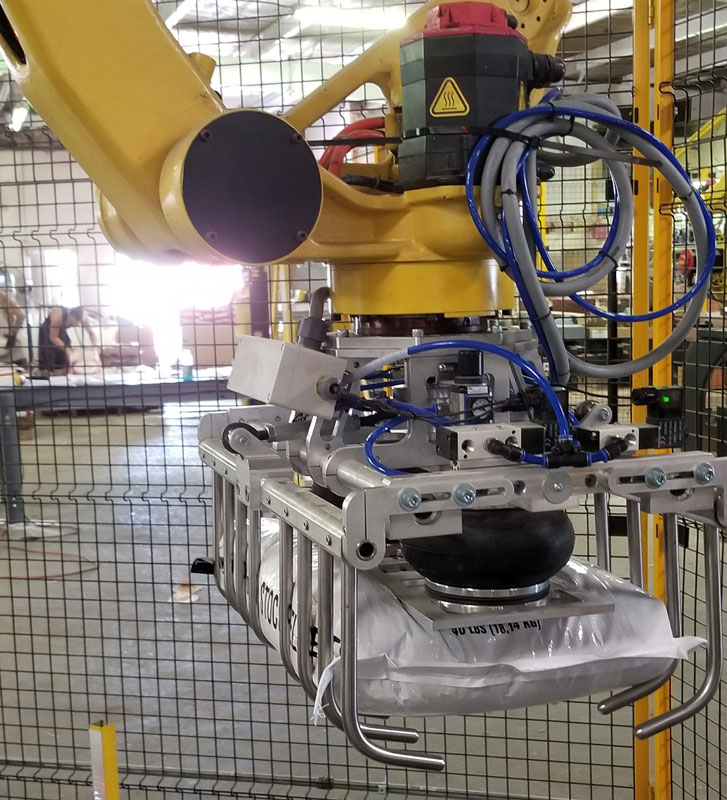

Next, a robotic bag palletizer with an end-of-arm tool picks up each bag and gently stacks them on a pallet. Pallets are automatically dispensed onto the conveyor and a slip sheet is applied. Once the pallets are full, they move through an automated pallet wrapper, and onto a filled pallet accumulation conveyor.

Next, a robotic bag palletizer with an end-of-arm tool picks up each bag and gently stacks them on a pallet. Pallets are automatically dispensed onto the conveyor and a slip sheet is applied. Once the pallets are full, they move through an automated pallet wrapper, and onto a filled pallet accumulation conveyor.

NEW! – For floppy bags filled loosely with products such as animal feeds, grains, seeds, fertilizers, minerals, aggregate, sand, rocks, potatoes, onions, and more…check out the Gantry Palletizers Systems page for affordable alternatives to traditional robotic arm palletizers.

Parts of an Automated Packaging & Palletizing System for 20-100 Lb Bags:

- Automatic Bag Placer

- Net Weigh Gravity Flow Bagging Scale

- Bag Top Reformer

- Bag Sewing Pedestal

- Bag Turner Conveyor

- Bag Flattener Conveyor

- Pacing and Squaring Conveyor

- Robot Pick Conveyor

- Robotic Bag Palletizer (or Gantry Palletizer System)

- Automatic Pallet Dispenser

- Slip Sheet Dispenser

- Automated Pallet Wrapper

- Filled Pallet Accumulation Conveyor

Ask a Question or Get a Price Quote!

Call: (979) 217-1480