Quickly heat seal many different types of bags or pouches with a continuous band sealer. We offer many bag sealers that can be customized to fit your type of bags, packaging system, and budget.

Ask a Question or Get a Quote. Use our Express Contact Form or call: (979) 217-1480

How does a Continuous Band Sealer work?

Bags or pouches are fed manually, or automatically, through the band sealer machine. As they move through the machine, they are precisely heat sealed before exiting downstream to additional conveyors or collection points.

This type of machine can seal large amounts of bags more quickly compared to an impulse sealer, or bar sealer, because the operator does not have to wait to load the next cycle of bags or pouches.

The amount of product sealed in each bag can range in size from 2oz. up to 110 pounds depending on the type of sealer used.

Watch a Video

What types of bags and stand-up pouches can these machines seal?

Continuous band sealers can seal a wide range of bags and stand-up pouches of almost any size or length. They are specially designed to seal thermo plastic materials like polyethylene, plastic-lined, foil bags, gusseted bags, pillow-type bags, and barrier bags. The height or width on some sealers can be adjusted as needed to accommodate different bag sizes.

Coffee Grounds Sealed in Foil Bag

What types of products are sealed in these types of bags?

Products sealed using continuous band sealers vary greatly and can include food products such as coffee, snacks, cookies, cereals, candy, chocolates, cannabis, dried fruit, pre-baked goods, cake mixes, grains, pastas, flour, MREs, peanuts, almonds, cashews, and more. They can also be used to seal agricultural products such as cattle feed, pet food, bird seed, hemp, as well as chemical powders, mortars, dyes, pharmaceuticals, and other products.

Sealing 20lb. Bags of Bird Seed

What type of band sealer do I need?

The type of band sealer required usually comes down to:

- desired sealing rate

- existing packaging line setup

- product requirements like vacuum sealing or nitrogen gas flushing

- validatable labeling

- bag types / thicknesses

- budget

The best way to narrow down the model options and get pricing is to use our Express Contact Form. A Tinsley sales engineer will respond within 24 hours or less with budgetary pricing and model selections.

Options range from small tabletop band sealers up to high-speed industrial band sealers.

What is the difference between a horizontal and vertical band sealer?

In a vertical band sealer, bags or pouches are standing upright as they move through the continuous heat sealer elements. In a horizontal band sealer, the bags or pouches are laying down on the conveyor as they move through the sealer. Some sealers can be adjusted to seal vertically or horizontally as needed.

Vertical band sealer

High-speed angled sealers are also available with flexible loading options. Angled bag sealers are used for bakery products, produce, poultry, magazines, textiles, paper, or other products that require horizontal or angled handling.

Angled band sealer

Do I need a conveyor with a continuous band sealer?

No. If the total bag weight is 1 pound or less, the bag or pouch can be suspended from the continuous band sealer and dropped off the end of the machine into a collection point without the use of a conveyor below.

Stand up pouches suspended from band sealer

Do continuous band sealers include vacuum sealers?

Vacuum sealers are optional components that can be added to a band sealer. They fit onto the front of a continuous band sealer machine and can also include a nitrogen flush packaging system.

Vacuum sealing with a flush of nitrogen gas

Vacuum sealers work by removing the oxygen from a bag our pouch before heat sealing. Hermetically sealed bags, that have been vacuum sealed, preserve the product inside by depriving it of oxygen and preventing the growth of mold or bacteria.

Typically, customers trying to vacuum seal more than 15 bags per minute will see the fastest return on investment with a continuous vacuum sealer.

Can these types of sealers print labels or embossed codes on the bags or pouches?

Yes, inkjet printers can be added to a continuous band sealer to print a code below the seal on the bags or pouches. A photo eye senses the bag and triggers the printer as it passes the printer. You can change the code instantly and include more than just alphanumeric characters.

An emboss coder can also be added to a continuous band sealer. The embosser sits on the exit end of the bag sealer. The emboss is applied after the bag has been sealed.

The standard embosser wheel holds 8 standard characters or 13 slim characters in a standard line. The font is the same for both and just the spacing between the characters is different. Please keep in mind that the embosser does not come with type and requires that individual pieces of type be purchased.

What are validatable bag sealers?

These types of continuous band sealers are capable of creating validatable seals on small and large bags in any cleanroom or sterile packaging environment. They offer precise management and control for temperature, pressure, speed, and seal quality.

All validatable medical and pharmaceutical systems include visual and audio alarms for deviations in heat, speed, and pressure. Common upgrades include compression belts to remove ambient air, as well as vacuum or gas flush systems for additional product purity and protection.

Can a bag top trimmer be added to a continuous band sealer?

Yes, a bag top trimmer can be added as an option to all sealers and can accommodate a 1.5in. to 4in. tall trim. The bag top trimmer can also be added to a sealer at a later date if necessary.

Sealing bags of salt using a continuous band sealer with a bag top trimmer

The trimmed part of the bag can be positively removed by the trim belts and venturi vacuum system. This is specially designed to prevent trim jams and works best with trimmed pieces measuring 1.5in. to 2.75in.

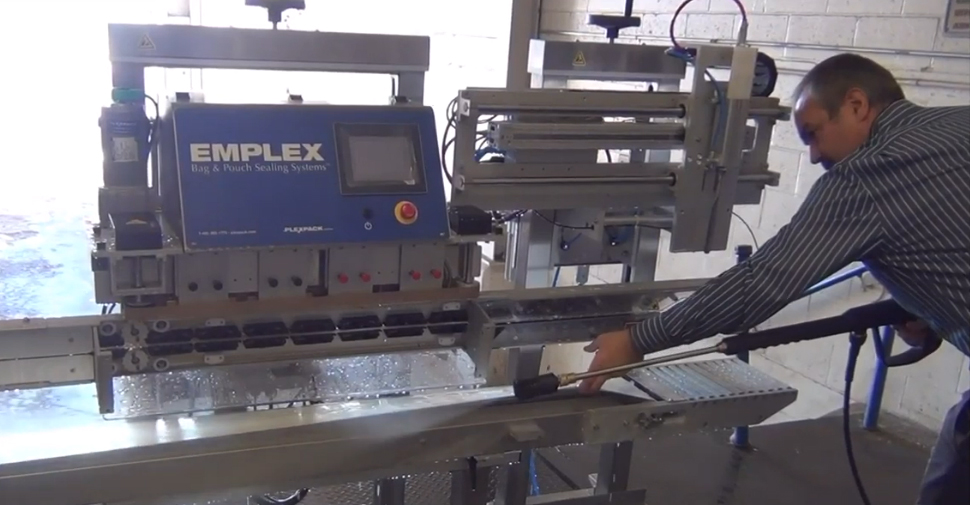

How do you clean a continuous band sealer?

If your application requires that the sealer be cleaned regularly, we offer NEMA 4 and 4X rated band sealers. All surfaces are designed for fast and comprehensive washdown, as well as corrosion protection. Frame and key components are constructed from 316 stainless steel and anodized aluminum parts with a chemical resistant coating. Conveyors and belts are either interlock belting or standard urethane.

Washing down a continuous band sealer using a power washer

These sealers can be washed down using a standard power washer and must be thoroughly dried before powering on.

Have additional questions or need more information?

Please visit the Bag Sealers page, or contact us.