This grain bagging system uses a type of bagger called an air packer to fill 50 pound bags with shelled corn, also known as shell corn, kernel corn, feed corn, or deer corn.

50 pound multiwall paper valve bag being filled with shelled corn

Grain Bagging System – Process Description

Shelled corn is conveyed into the grain bagging equipment from an external storage silo, where it is first tumbled and cleaned. Then, it flows into an auger conveyor that lifts the corn into a surge hopper located above the bagging machine.

Auger conveyor lifts corn into surge hopper above bagging machine

The hopper contains a high level and low level sensor. The high level sensor tells the operator when the hopper is getting too full and also stops the auger conveyor. A warning light also illuminates when the level of corn gets too high. The low level sensor will turn the auger conveyor on to refill the hopper.

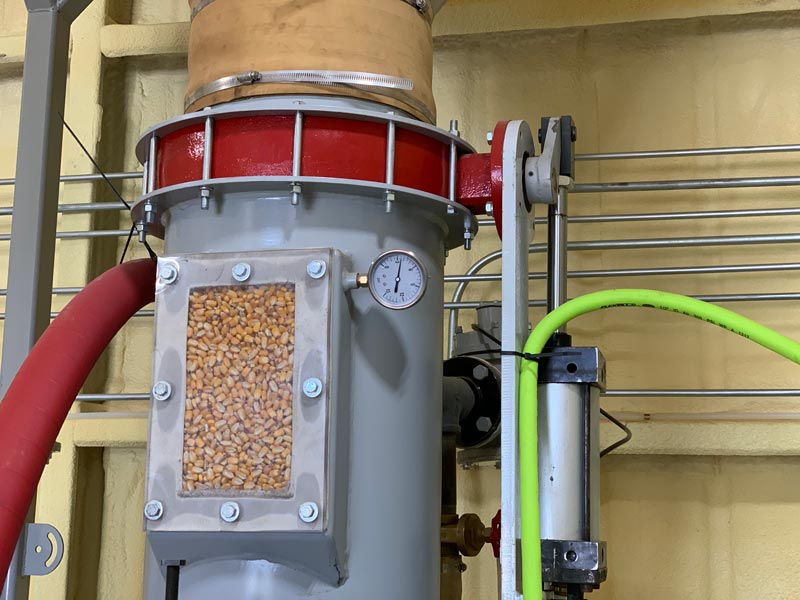

Next, the shelled corn flows by gravity from the hopper and into the air pressure chamber located on the bagger. Air pressure then blows the corn into a custom printed multiwall paper valve bag.

Air chamber filling up with shelled corn before being blown into a valve bag

Bagger filling 50 lb. valve bag with shelled corn

This type of bag is self-closing and DOES NOT require sewing. The bagging machine continues to fill the bag until a set target weight of 50 pounds has been reached. At 50 pounds, the bag seat automatically tips and drops the bag onto an incline conveyor that takes it a short distance to a gravity roller conveyor. The bag gently rolls toward an operator that picks up the bags and stacks them on a wooden pallet.

Filled bags move up incline conveyor to gravity roller conveyor for stacking on pallet

Once the pallet has been filled, it is placed on top of an automatic pallet wrapping machine. The machine spins the pallet as stretch wrapping plastic is wrapped around it. This helps to secure the bags of shelled corn for shipping or storage.

Pallet stretch wrapping 50 lb. bags of shelled corn

This type of bagging system that includes an air packer allows 1 operator to fill 6 -8 bags per minute under normal operating conditions.

Watch a Video

Need pricing fast or have a question?

Use this express contact form! A Tinsley Equipment Company sales engineer will email you current pricing for all equipment and system components listed on this page usually within 24 hours or less. Need to speak with someone? Call: (979) 217-1480

* All fields are required.

If you are interested in a similar bagging system that fills open top bags, please see this article called Bagging Deer Corn and Other Grains into 30 lb to 50 lb Bags.