The automatic bag placer machine picks up, hangs, and clamps an empty open mouth bag onto a bagger before product is discharged into a bag. Up to 20 bags per minute are possible and it works with both new / existing net weigh and gross weigh bagging scales. With this type of automation, one full-time operator can be removed from the bagging system.

This machine is one of the simplest and most reliable robotic bag placers on the market for hanging most paper bags, as well as some plastic and polywoven bags. A key feature that differentiates it from other bag placers is that you are still able to manually place bags during an outage, interruption, or maintenance to the bag placer. Fully enclosed bag placers and systems don’t allow for this and require entire line shut down, while problems are being addressed.

Watch a Video:

Process Description

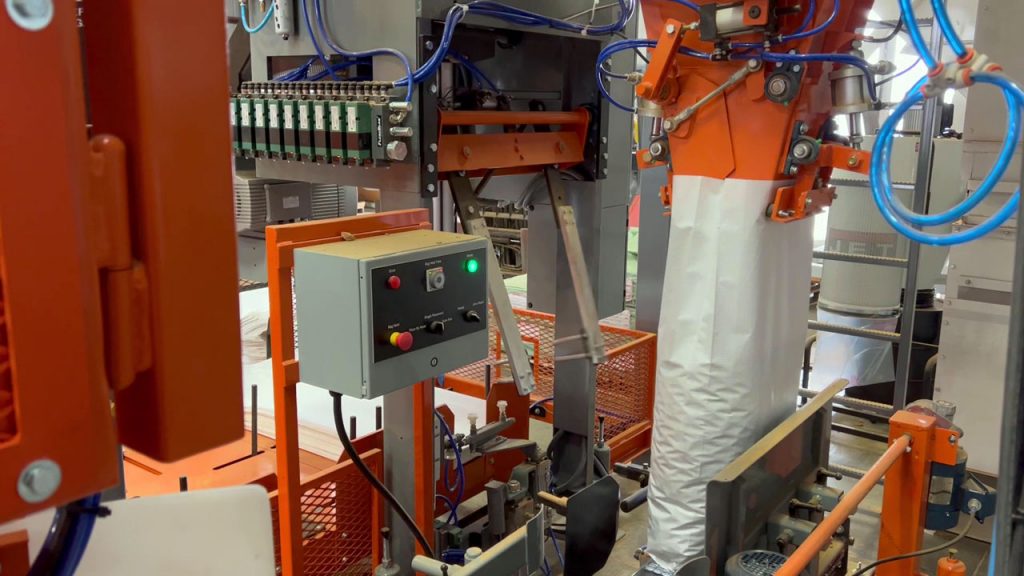

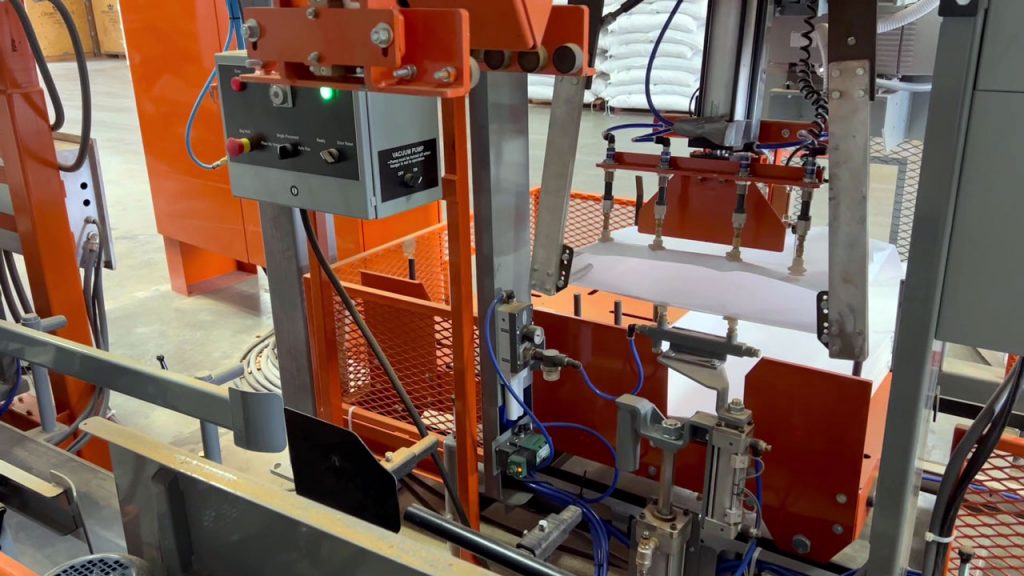

The automatic bag placer first picks up an empty bag using suction cups. Then, 2 arms spread open the mouth of the bag and hold it for hanging using a precise amount of tension.

Picking up an empty bag and opening the mouth

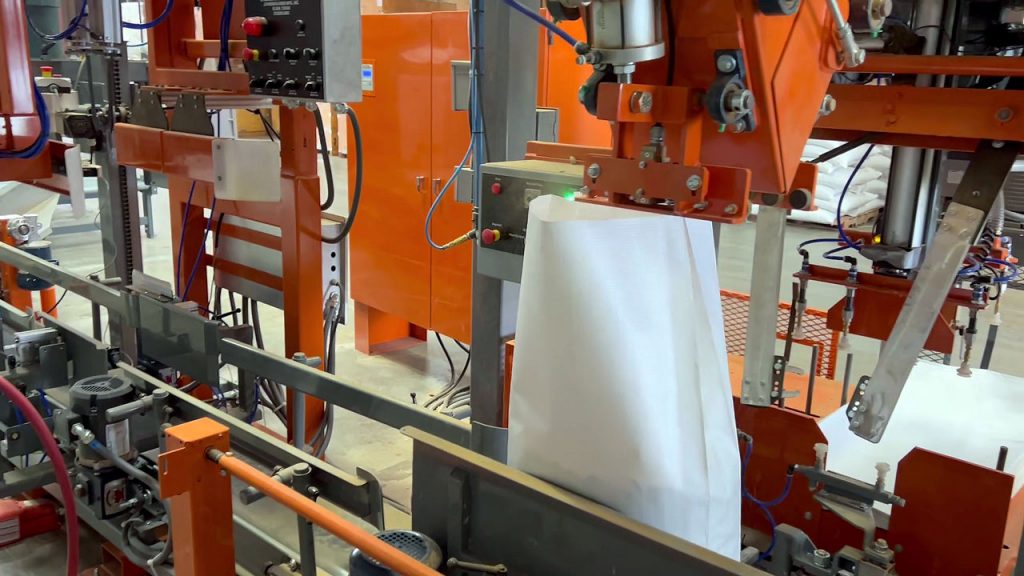

Next, the arms rotate and hang the empty bag on an integrated bag clamp. This holds the bag to the bagging scale, while product is discharged into the bag.

Hanging or positioning an empty bag on scale with an integrated clamp

Once the bag is filled to a set target weight, it drops onto a bag closing conveyor. An automatic bag top reformer (or operator) then reforms the top of the bags before they are sent through a bag sewing system before manual stacking or robotic palletizing.

Clamp releases filled bag onto closing conveyor

Bag moves through an optional bag top reformer before sewing

Bag magazine end of bag placer (holds up to 400 empty bags)

Ready for a bagging system upgrade?

Speak with one of our sales engineers today and get a fast price quote!