Automating the stacking, or palletizing, of bags at the end of a packaging line with a used robotic palletizer can provide a fast return on investment. Robotic palletizers can be oriented in any direction to accept bag inflow from a new or existing bagging system. They minimize the risk of repetitive injuries caused by stacking heavy bags on shipping pallets, while simultaneously reducing labor and staffing requirements.

Automating the stacking, or palletizing, of bags at the end of a packaging line with a used robotic palletizer can provide a fast return on investment. Robotic palletizers can be oriented in any direction to accept bag inflow from a new or existing bagging system. They minimize the risk of repetitive injuries caused by stacking heavy bags on shipping pallets, while simultaneously reducing labor and staffing requirements.

What types of used robotic palletizers do you sell and install?

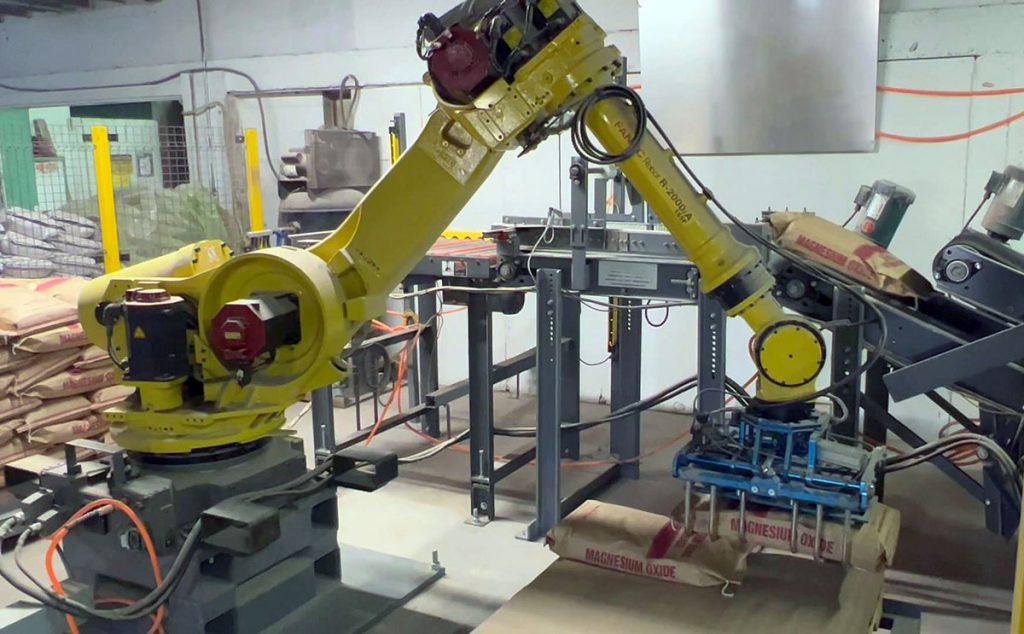

We sell used, or reconditioned, Fanuc palletizing robots outfitted with a bag tool that gently picks up bags from a pick conveyor and places them in a set pattern on a shipping pallet resting on a platform, or directly on the floor.

Watch a video of a used robotic palletizer added to an existing bagging line:

We also sell, install, and support new Fanuc robotic palletizers, as well as Kawasaki robotic palletizers.

NEW! – For floppy bags filled loosely with products such as animal feeds, grains, seeds, fertilizers, minerals, aggregate, sand, rocks, potatoes, onions, and more…check out the Gantry Palletizers Systems page for affordable alternatives to traditional robotic arm palletizers.

Are there significant cost savings when buying a used robotic palletizer?

Yes. On average, you can save about 20-30% buying a used robotic palletizer that has been refurbished to work just as well as a new robot.

What types of reconditioning services are performed on each used robotic palletizer before sale?

Here’s a list of the reconditioning or tune-up services performed on each used Fanuc robot:

- Purge and grease all gear boxes, RV reducer cavities, and bushings

- Check and replace seals as need

- Re-grease balancers and other bushing / bearings on the mechanical manipulator

- Test and inspect teach pendants / cables and replace overlays if needed

- Repaint with new stickers, logos, and witness marks when available (custom paint jobs are available upon request)

- 10-hour continuous operation test including Repetitive Position Accuracy Testing (RPAT) for each robot

- Gear backlash adjustment, if necessary, test and inspect belts or pulleys

- Motor brake drop test

- Visually inspect for damaged connectors and replace if necessary

- Test all cables for wear and damage

- Reset control cabinet back to factory specifications – ex. External e-stops removed; external holds removed

- Clean all cabinet heat exchange equipment including fans and filters

- Remove custom input and output file comments and delete existing programs from previous use

- Re-install proper licensed software in all Fanuc robots

- Change CPU battery and encoder batteries

- Provide complete service documentation / traveler with each robot

In addition to all used robot refurbishment services, a factory acceptance test is performed with each customer to approve the system with their bags, products, and weights before shipment of the bagging and/or palletizing system.

Factory acceptance test of palletizing system with used robot bag stacker

What else is required to add a used robotic palletizer to an existing bagging system or packaging line?

To add a used robotic palletizer at the end of a bagging system you will most likely need to include the following:

- Bag flattener conveyor – removes air from the bags and makes them more uniform in size for before stacking them on a pallet

- Pacing and squaring conveyor – controls the speed of bag presentation to the robot and makes sure the bags are straight when presented to the robot’s end-of-arm bag tool

- Robot pick conveyor – this is the conveyor where the bags are picked up from

- Pallet stack zone – one or two-pallets that can be on either side of the robot

- Safety fencing

Additional opportunities for system automation:

- Automatic pallet dispenser and slip sheet applicator

- Automated pallet wrappers

- Filled pallet accumulation conveyors

What bag weights can these used robotic palletizers stack?

They can easily stack open mouth bags and valve bags that weigh 20 Lbs. to 110 Lbs. each. Depending on your requirements, they can also stack payloads weighing more than 110 Lbs. Most palletizing robots can realistically stack bags at a rate up to 12 bags per minute.

How much floor space does a robotic palletizer require?

On average you will need a 20 ft by 20 ft area at the end of your bagging system. We have installed these types of robotic bag palletizing systems in some tight spaces!

Watch a video of a used robotic palletizer installed in an existing feed mill with limited floor space and ceiling height:

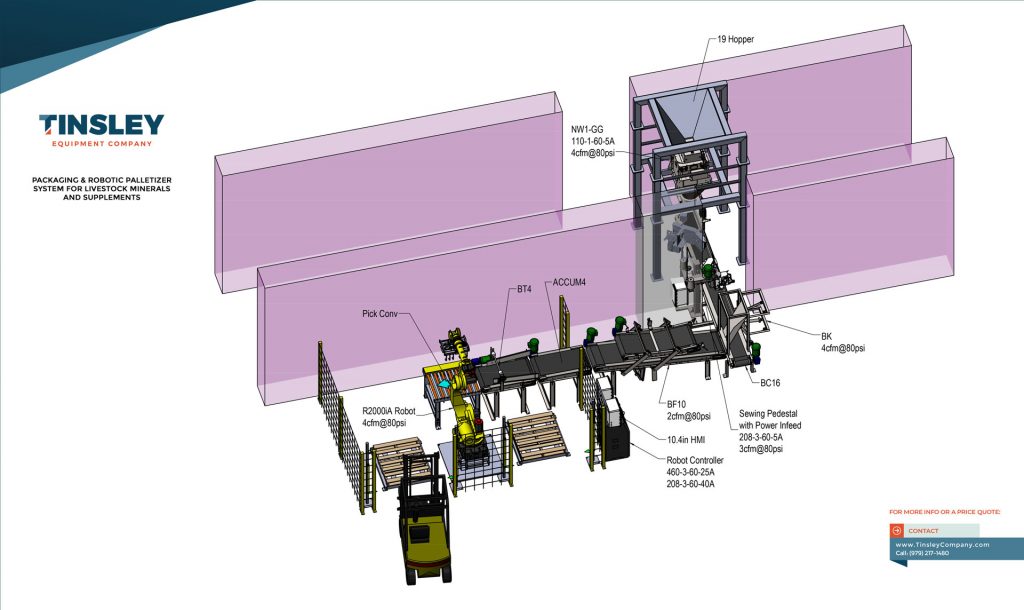

Here’s what a side-by-side pallet stacking arrangement would look like:

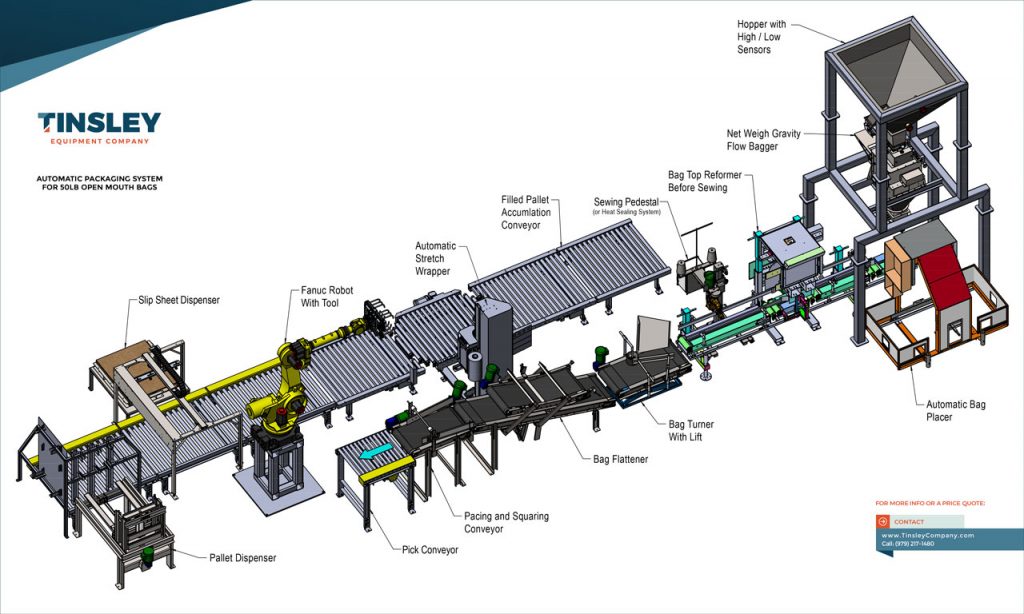

Here’s what a fully automated bag packaging system would look like:

Need pricing fast or have a question?

Use this express contact form! A Tinsley Equipment Company sales engineer will email you current pricing for all equipment and system components listed on this page usually within 24 hours or less. Need to speak with someone? Call: (979) 217-1480

* All fields are required.

Learn more about bag filling, robotic palletizers, and automation: