End-of-line robot picking up 100 lb. bag of minerals using a bag gripper tool

A contract packaging company recently added an end-of-line robot to their existing valve bag filling system. The new robotic palletizing system includes bag handling and robotic pick conveyors, a used Fanuc robotic arm that has been reconditioned with a bag gripper tool, and an automated pallet and slip sheet dispenser.

With the added palletizing automation, the entire system is now able to fill and stack 100 lb. paper valve bags at a rate of 10-12 bags/minute. The company can also quickly swap out settings to fill and stack 50 lb. valve bags at a rate of 15-16 bags/minute.

Watch a Video:

Process Description

An operator fills 100 lb. craft paper valve bags with abrasive minerals using 2 valve bag air packers. These types of valve bag filling machines use low air pressure to push the minerals into a bag. Using a self-sealing valve bag for this type of application also ensures minimal product spill and dust and reduces the need for additional bag closing equipment.

Once filled, the bags automatically tip and drop onto a bag discharge conveyor. Then, the bags move through a bag turner conveyor that correctly orients them before they are conveyed up an incline conveyor to a bag pacing conveyor. The pacing conveyor controls the speed of the presentation of the valve bags to the Fanuc robotic arm via a squaring conveyor and a robot pick conveyor. Additionally, a bag printer is used to print a unique trackable and scannable code on each bag while on the pacing conveyor.

Bag discharge conveyor under air packers and bag turning conveyor

Reverse view of 100 lb. valve bags containing minerals moving through a bag turning conveyor and up incline conveyor to pacing conveyor with a bag printer

Next, the bags move into the robotic palletizing system where the robotic arm with a bag gripper tool gently picks up the bags and stacks them on an empty pallet that includes a slip sheet. The end-of-line robot stacks the 100 lb. bags using a custom stored recipe that generates a specific stack pattern for this particular product. Switching the entire system to fill and palletize 50 lb. bags is also a simple process. It only requires the operator to change the target set fill points on the air packers and load another stored bag palletizing recipe on the robot’s remote control.

End-of-line robot picking up 100 lb. bag of minerals using a bag gripper tool

Additional view of the end-of-linerobot picking up 100 lb. valve bag of minerals using bag gripper tool and stacking on an almost full pallet

As mentioned earlier, this system also includes an automatic pallet dispenser with automatic slip sheet dispensing. Empty pallets are loaded into a magazine. When an empty pallet is requested by the system, it is dispensed from the magazine and is conveyed to an automatic slip sheet dispenser. One slip sheet is applied to an empty pallet before both are conveyed to a set position where the robot starts to stack bags on top of it.

Empty pallet being dispensed from automatic pallet dispenser

Automatic slip sheet dispenser placing slip sheet on a pallet

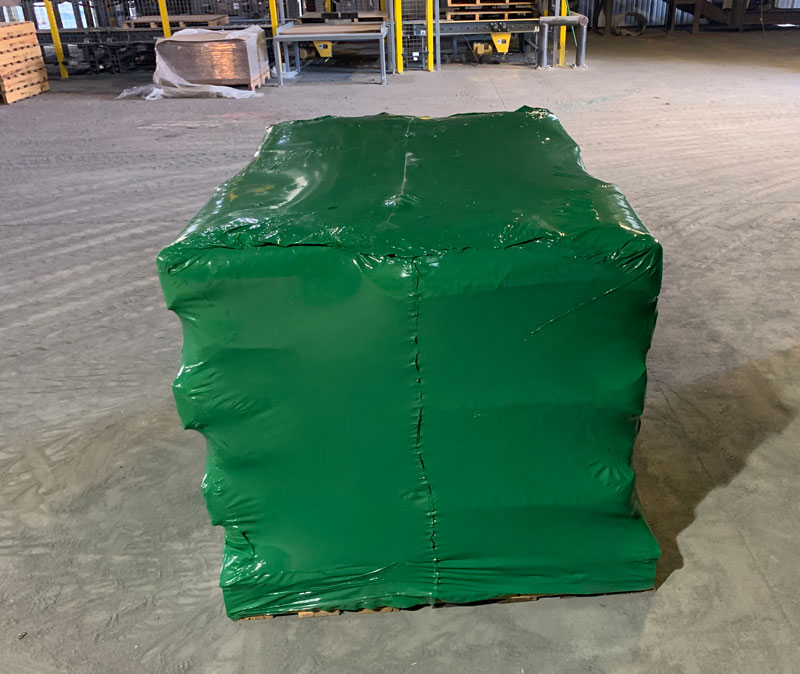

Once a pallet has been completed, it moves down a filled pallet take away conveyor where an operator removes the pallet and places shrink wrap over it. Then, the operator applies heat to the shrink wrap which causes it to contract and hold the bags in place on the pallet. Then, the operator removes the pallet for shipping or storage.

Shrink wrapped pallet of 100 lb. valve bags

Ask a Question about this End-of-Line Robot and Valve Bag Filling System

or get a price quote!

Call: (979) 217-1480