This system precisely unloads free-flowing seeds, feed, corn, and more from a Buckhorn CenterFlow seed pro box into open mouth bags using an open mouth bag filler. The system can also be used to bag other free-flowing agricultural products like bird seed, wheat seed, deer corn, animal feed, fertilizer, pellets, and more.

Process Description

The seed pro box is placed above the open mouth bagger using a fork lift or tractor. Then, a manual air-powered seal raises up to cover the outlet of the pro box. The slide gate is opened allowing the stored material to flow from the seed box into the inlet above the bag filling machine. The operator places an empty bag on the bag filler and presses the foot pedal to start filling the bag. It is filled by weight using a digital load cell with controller. When the bag has been filled to the set target weight, an air-powered bag clamp automatically releases the bag and it is ready for sewing and palletizing.

This particular mobile bagging system is mounted on casters allowing for movement within a warehouse or packaging area. It uses 220/1/60 power and 80 PSI compressed air for operation. Any type of material stored in a seed pro box, such as free flowing corn seed, wheat seed, rice seed, soybean seeds, or animal feeds can be packaged using this type of system.

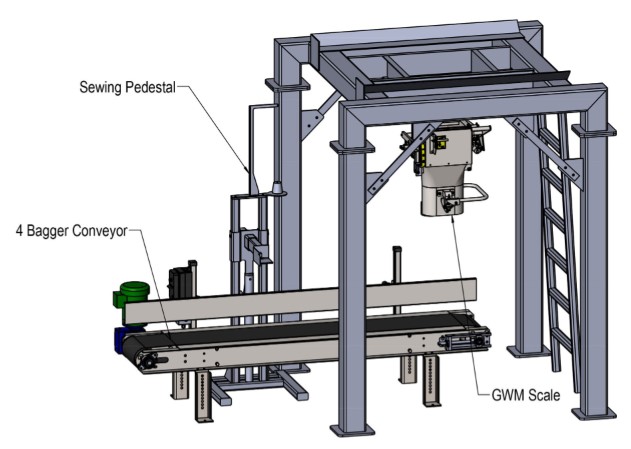

Stationary Seed Pro Box Discharge Stand and Scale Support

We also offer a turnkey system to discharge free-flowing products from a seed box into an open mouth bagger. After filling, bags can be guided through a bag sewing system at an approximate rate of 4 bags per minute. Higher bagging rates can be achieved using a bagging machine with a pneumatically powered bag clamp and a higher speed bag sewing system.

Front view of seed pro box discharge stand and bagging scale support

Top view of seed pro box discharge stand and bagging scale support

Digital bagging machine attached to a seed probox discharge stand

Bagging feed discharged from a Buckhorn CenterFlow seed pro box

Bagging fertilizer discharged from a Buckhorn CenterFlow seed pro box

Ask a Question or Get a Price Quote!

Call: (979) 217-1480