« Equipment and Systems

-

- Open Mouth Baggers

- Valve Bag Filling Machines

- Bulk Bag Filling Machines

- Bulk Bag Unloaders

- Bag Sewing Machines

- Bag Sealing Equipment

- Bag Handling Conveyors

- Manual Palletizing Systems

- Robotic Bag Palletizers

- Gantry Palletizer Systems

- Automated Pallet Wrappers

- Automatic Bagging

Machines & Systems - IBC Blending

- Stainless Steel Intermediate Bulk Containers

Bag Sewing Machines and High-Speed Closers

Use a bag sewing machine and high-speed closer as a part of a complete bagging line.

Sew, stitch, and close a variety of open mouth style bags, including paper, plastic, poly-woven, and BOPP, with a bagging system. Bag sewing machines can be placed above a conveyor. They can also be portable or hand-held. These machines are ideal for sealing sacks filled with products such as feed, corn, nuts, rice, beans, aggregate, and more.

An industrial high-speed bag sewing system that is mounted on a pedestal above a conveyor usually sews bags at rates up to 20 bags per minute. A portable or hand-held bag sewing machine can close up to 8 bags per minute. Bag sewing machines can also be incorporated into larger packaging systems and combined with an automatic bag placer, bag top reformer, automatic tag placer, open mouth baggers, conveyors, or bag palletizing robots.

Jump to a section below:

- High-speed Bag Sewing Machines and Closers

- 4 Bags per Min Sewing System

- Portable and Hand-Held Bag Sewing Machines

High-Speed Bag Sewing Machines and Closers

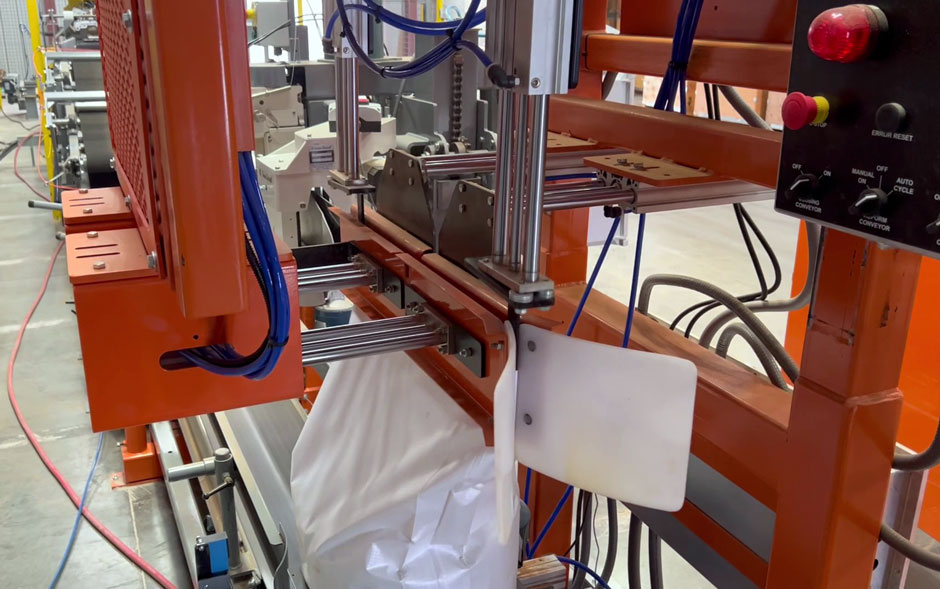

These industrial bag sewing machines are incorporated into larger bagging lines and can stitch and sew up to 20 bags per minute or more. They close multi-walled paper, woven, BOPP, and laminated woven polypropylene open mouth bags at medium to high speeds. The industrial pedestals are manufactured to work with popular types of sewing heads from companies like Fischbein, Newlong Industrial, and Union Special. Start-Stop and thread / tape cutter photo eyes are standard and all pedestals are factory tested prior to shipping. Additional options include thread cutter controls, thread break detection kits, and high-speed power infeeds with fold over.

Watch a Video:

For fully automated bagging systems, we also recommend using an automatic bag top reformer. The bag top reformer is placed after the bagging machine and before the sewing pedestal. It automatically reforms the bag tops of flat, pillow type bags that can stand upright by themselves on a conveyor. The automatic bag top reformer can also be used with side gusseted bags. However, the fingers on the reformer will pull the gussets outward rather than inward.

Watch a Video:

Automatic tag placers can also be used with bag sewing machines. They can place and apply 3"x5", 3"x6", or 4"x6" tags that are sewn into each bag. Variable tag positioning is available through controller times.

Semi-automatic high-speed bag sewing machines are also available with sewing heads made by Union Special and Newlong. These can be mounted to a heavy duty, adjustable sewing pedestal. These include a variable speed drive, start and stop photo eyes and PLC controls, disconnect and E-Stop per NEC standards, with quick height adjustment including gear box with chain assembly and HIWIN linear guide bearings and rail, swing away sewing set-up, motor and controls designed for use with both Union Special and Newlong industrial sewing heads. An operator is required to feed the bags into these types of sewing machines.

4 Bags per Min Sewing System

Close, sew, and stitch shut open mouth bags containing products like seeds, feeds, grains, powders, corn, and more. This system is intended for single operator use. It includes a pedestal mounted bag sewing head and an 8 foot long bag closing conveyor with variable speed controls. Just like the high-speed bags sewing machines, this system includes a sensor that automatically starts and stops the sewing head as bags enter and exit the system down the conveyor belt.

Close rate: up to 4 bags per minute

Bag types: paper and poly woven open mouth bags

Conveyor: 8 ft. long by 12 in. wide bag closing conveyor with 18-21 in. adjustable height and adjustable back rail

Controls: digital variable conveying speeds with automatic start and stop

Sewing: sewing head (can also be portable / hand-held) with a self-standing adjustable mounting pedestal and 1 cone of thread

Control air: no compressed air required

Electrical: 110 Volt / 1 Phase / 60 Cycle

Watch a Video:

Hand-held and Portable Bag Sewing Machines

Close and stitch shut paper, plastic, and poly woven open mouth bags and sacks. This portable bag closer produces a single thread chain stitch and is self-lubricating.

For hand-held sewing and bag stitching only. No pedestal or conveyor included.

Add the balancer option for a gentle retraction of the sewing machine to an overhead position.