Tinsley Equipment Company recently performed a test run for a new feed producer that was interested in bagging horse pellets into 25 lb bags.

These type of supplement horse pellets were made of coastal hay and measured about ¼-1/2” in diameter and about 1 inch long. The producer farms different types of coastal hay and Bermuda grasses and wanted to learn more about the bagging and packaging process.

Horse pellets (or hay pellets) used for feed supplement

To run the test, Tinsley Equipment Company set up a 25 cubic foot bagger supply hopper, a digital gross weigh bagging machine with a pneumatic bag clamp, a temporary box platform under the scale to support the filled bag, and then a table for manual bag top folder over and handheld sewing. Closed bags were manually transported and stacked on pallets resting on a truck trailer. Finished pallets were manually wrapped and secured to the trailer before transporting them to a feed store for final sale.

Process Description

Discharging horse pellets from a 2,000 lb bulk feed tote bag into a Buckhorn CenterFlow Seed Box

Horse pellets were discharged from a 2,000 lb bulk bag into a portable Buckhorn CenterFlow Seed Box. Then, the box was transported via forklift into the test facility and discharged into the bagger supply hopper.

Discharging horse pellets from Buckhorn CenterFlow Seed Box into hopper

After the gross weigh bagging machine was calibrated to fill the bags with 25 lbs of horse pellets, an operator would manually place a bag on the fill spout and trigger the weigh filling process by depressing a wand located on the right side of the bagging machine.

Placing a 25 lb bag on the bagging machine while other operator transports filled bags to makeshift bag sewing station

Gross weigh bagging machines weigh the material in the bag as it is being filled. Once the digital scale registers the set target fill weight of 25 lbs, the pneumatic bag clamp automatically releases the bag from the scale where the operator would guide it down onto the temporary box platform below. Then, the operator would manually transport the bag to the makeshift bag sewing station.

IT6000E batch weighing controller attached to bagging machine is set to target fill weight of 25 lbs

At the bag sewing station, one operator would pick up a bag, fold over the top, and hold it in place while another operator would sew the bag shut using a handheld bag sewing machine.

Handheld sewing head closing 25 lb bag of horse pellets

After sewing, one of the operators would manually transport the closed bags and stack them on a pallet resting on a truck trailer.

Stacking 25 lb bags of horse pellets on pallet in truck trailer

Results

This test run and packaging process was VERY manual and labor intensive, especially during a HOT Texas summer! However, the team of operators was still able to bag and palletize over 4,000 lbs of horse pellets in about 6 hours.

Opportunities for Labor Reduction and Efficiency Gains

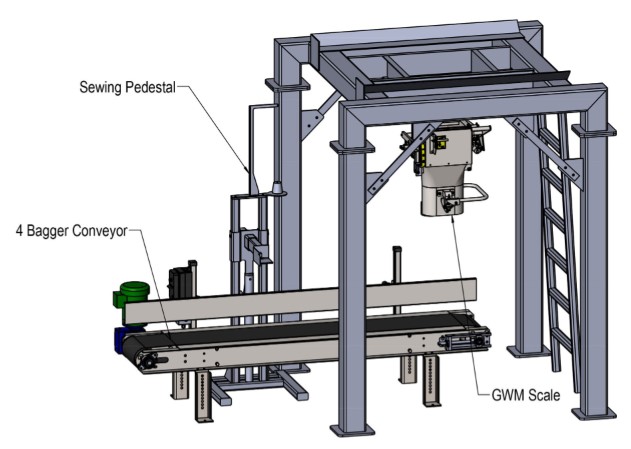

After the test run, the new feed producer decided to setup a 4 bag per minute packaging system to fill 25 – 50 lb bags with feed pellets using 1-2 operators. This is one of our most popular types of bagging systems and generally includes:

- 25 cubic foot bagger supply hopper

- Digital gross weigh bagging scale with add on pneumatic bag clamp

- 4 bag sewing system

Future additions to this type of feed pellet bagging operation could include a manual bag palletizing system and eventually a robotic palletizer.

Need pricing fast or have a question?

Use this express contact form! A Tinsley Equipment Company sales engineer will email you current pricing for all equipment and system components listed on this page usually within 24 hours or less. Need to speak with someone? Call: (979) 217-1480

* All fields are required.

Buckhorn CenterFlow Seed Box Discharge Stand

Instead of using a traditional bagger supply hopper, a Buckhorn CenterFlow Seed Box discharge stand could also have been used to build out a similar system with comparable bagging speeds.

Front view of Probox discharge stand and bagging scale support

digital bagging machine attached to a buckhorn pro box discharge stand