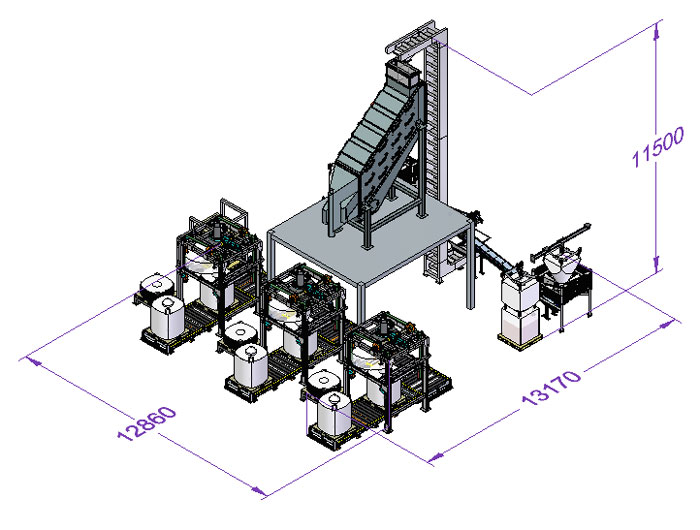

Drawing of a high-speed big bag filling system. Measurements are in millimeters.

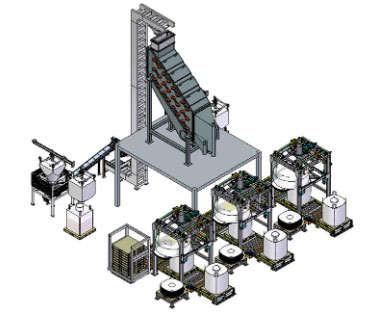

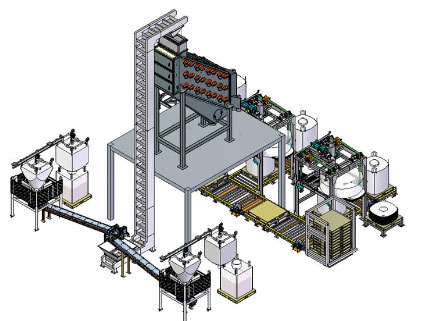

In this hi-speed big bag filling system, raw sugar is unloaded from big bags, or bulk tote bags, conveyed to a vibratory screen where it is separated into 3 fractions and one waste fraction, and then re-packaged into big bags.

Process Description

Raw sugar is discharged from big bags using a dual bulk bag unloading system. The big bags are emptied into a hopper and the raw sugar is conveyed to a bucket elevator using a flexible auger conveyor. The raw sugar is conveyed to the top of the system using a z-style bucket conveyor, where it is discharged onto a 3-deck vibratory screen.

The vibratory screen separates, or sifts, the raw sugar into 3 fractions and one waste fraction. Each fraction is conveyed to a hi-speed big bag filling station. Each station contains an automated pallet dispenser. Once the big bag has been filled to a set target weight, it is conveyed to the end of the roller conveyor, where a forklift operator will transport it to shipping, storage, or to downstream bulk processing equipment.

Ask a Question -or- Get a Price Quote!

Call: (979) 217-1480