Newlong DS-9C Bag Sewing Head

The Newlong Bag Sewing Machine DS-9C high-speed industrial sewing head is a popular choice for businesses seeking to improve their bag closing operations. In this article, we will explore the key features of the Newlong DS-9C, how it works in conjunction with a power infeed system, and the benefits it brings to bag closing processes.

Key Features of the Newlong Sewing Machine DS-9C

The Newlong DS-9C is designed to close various types of bags, such as kraft paper, cotton, and woven polypropylene, at speeds of up to 2,700 stitches per minute. Its sturdy construction and high-quality components ensure durability and reliability, making it an ideal choice for high-throughput production lines. With an automatic thread chain cutter, the DS-9C provides clean and secure bag closures.

Newlong Bag Sewing Machine DS-9C Left Side Exit

Enhancing the DS-9C with a Power Infeed System

Newlong DS-9C mounted on industrial bag sewing system pedestal with power infeed

A power infeed system can be added to the Newlong DS-9C sewing head to further improve efficiency and quality. This system automatically pulls in the top of the bag, aligns it, and ensures consistent and secure closures. An attachment can also be added that folds the top of the bag over before sewing providing a slightly cleaner appearance and tighter seal.

A power infeed system allows the same operator to place and fill a bag and then quickly guide it into the bag closing system without too much effort, thus greatly increasing efficiency.

The power infeed system works in conjunction with the sewing head through a series of steps:

- Bag guiding: A bag guide aligns the top of the bag with the sewing head’s infeed.

- Power infeed: Driven belts or rollers pull the folded bag top into the sewing head, maintaining tension and speed.

- Bag top folding: A folding mechanism folds the top of the bag over for a clean, consistent finish.

- Sewing: The sewing head sews the folded edge using a continuous chain stitch.

- Thread chain cutting: An automatic cutter trims the thread chain, leaving a neat and secure closure.

Thread break detector kit for Newlong bag closing equipment

Benefits of the Newlong Bag Sewing Machine DS-9C and Power Infeed System

Investing in a high-speed bag sewing head like the Newlong DS-9C, combined with a power infeed system, brings several benefits to your bag closing operations:

- Increased efficiency: The fast sewing speed and automated infeed process reduce the time spent on bag closures, allowing for higher throughput.

- Improved consistency: The power infeed system ensures proper alignment and folding of bag tops, resulting in uniform closures.

- Enhanced durability: The Newlong DS-9C’s robust construction ensures long-lasting performance, reducing downtime and maintenance costs.

- Reduced labor requirements: The automation of the bag closing process allows for fewer manual interventions, lowering labor costs.

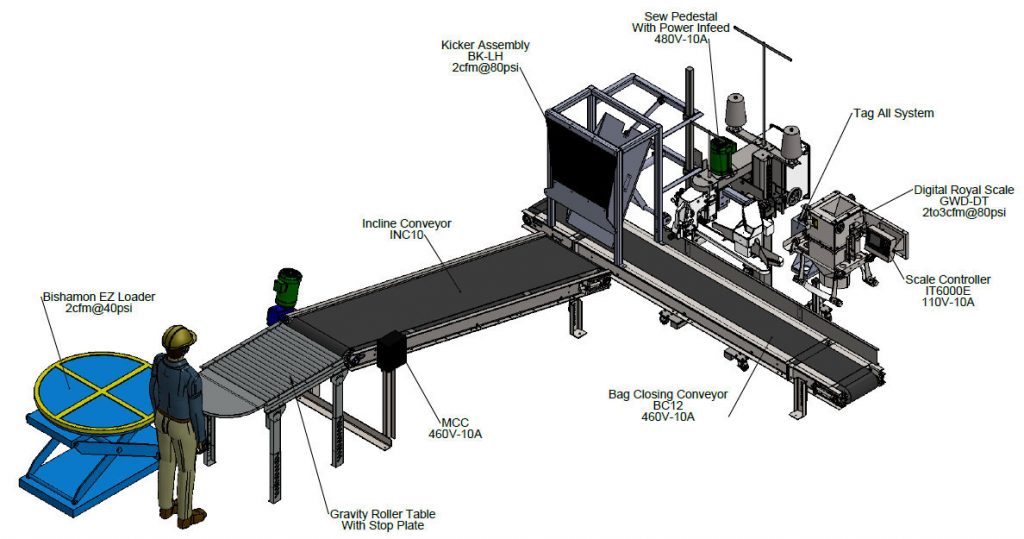

Typical Bag Sewing System with Newlong DS-9C

Custom bag sewing system with Newlong DS-9C and Union Special Power Infeed for use with Auto Bag Top Reformer

The most popular type of bag sewing system that we sell contains the following equipment for most plain sew applications:

- Newlong DS-9C Industrial High Speed Sewing Head – Newlong DS-9C sewing head with pneumatic thread cutter

- Newlong Power Infeed Plain Sew – Newlong CP4900-WOF power infeed for plain sew applications (can also substitute this with a Union Special power infeed for use with an automatic bag top reformer system)

- Newlong Power Infeed Motor and Controls – Includes motor, starter, overload, mounting bracket, installation, and testing with sewing pedestal

- Newlong DS-9C Thread Cutter Controls – Part No. 3770300450 – Includes photo eye, valve, and regulator to control knife

- Thread Break Detector Kit

- Industrial Sewing Pedestal – Includes variable speed drive, start/stop photo eyes and PLC controls, disconnect and E-Stop per NEC standards, with quick height adjustment, and casters. Designed for use with Newlong sewing head.

- Tagging System – mounting bracket for manual tag placement with mounting bracket to support from conveyor

- 8, 10, or 12 Foot Long Bag Closing Conveyors with a Flat Belt – 12 inches wide. Includes gear motors and controls, with AC variable speed drive, take up bearings, stainless belt lacing, bag back rail, NEMA4X/IP65 motor controls cabinet and 1hp AC inverter duty motor. Longer conveyors are recommended if a bag kicker will be used at the end to transfer closed bags 90 degrees to a manual palletizing station or bag palletizing robot.

Packaging system layout drawing showing location of industrial bag sewing system

Conclusion

For businesses in need of reliable bag closing equipment, the Newlong Sewing Machine DS-9C, coupled with a power infeed system, offers an effective solution. By incorporating this industrial bag sewing system into your packaging line, you can achieve greater efficiency, consistency, and durability in your bag closing operations. Whether you’re in the animal feed, agriculture, or chemical industry, the Newlong DS-9C is a worthwhile investment to elevate your bag packaging process.

Ask a Question -or- Get a Price Quote

Call: (979) 217-1480