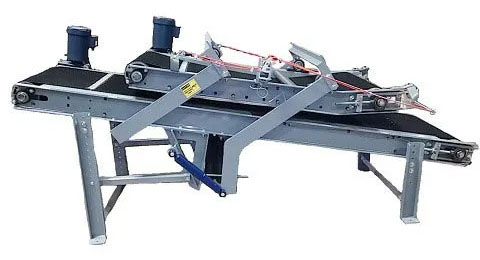

A bag flattener conveyor is designed for flattening both filled valve bags and open mouth bags to make them more uniform in shape to stack on a shipping pallet. They are flattened as they move through two conveyors with the upper conveyor applying adjustable force to the top of the bag. Typically, the bag flattener also acts as an incline conveyor that elevates the bags to the inlet of a palletizing station.

Video Demonstrations of a Bag Flattener Conveyor:

Process Description

Filled bags in an automatic bagging system can be irregularly shaped, bottom-heavy, or not uniform in size, after they are filled or sewed shut. As they move through a typical bagging system, they are knocked down, or kicked, so they travel label side up, or bottom first, into an incline bag flattener conveyor. As they move through the bag flattener conveyor, they are gently squeezed, compressed, or flattened so that they are more brick-like and uniform in shape for stacking. The product inside the bag becomes more evenly distributed or dispersed inside the bag.

After exiting the bag flattener conveyor, they are discharged at a gravity roller conveyor where operators pick them up for manual palletizing. In an automatic bagging system, the bags are discharged onto a pacing or squaring conveyor where they are positioned and aligned for pick up by a robotic arm or gantry palletizer system.

Note: Another option for leveling out the product inside of filled bags is to use a square roller conveyor.

View Pictures of Bag Flattener Conveyors

Ask a Question -or- Get a Price Quote!

Call: (979) 217-1480