A magnetic drum separator removes ferrous metal from dry, free-flowing bulk solids. It is self-cleaning and available within a housing or as the magnetic drum only.

How does a magnetic drum separator work?

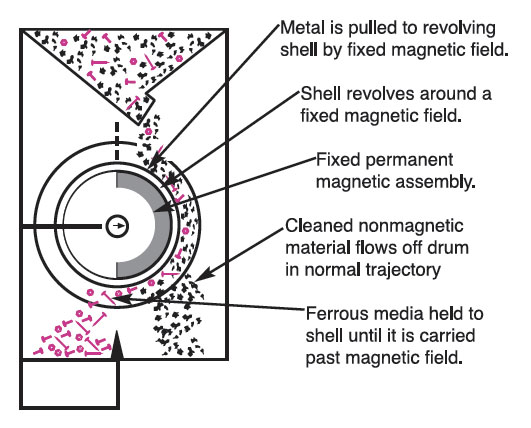

A uniform product flow is introduced to the magnetic drum separator using a vibratory feeder or conveyor. The material enters the top of the housing and flows across the surface of the drum. As the drum shell rotates around the stationary magnetic field, all non-ferrous material, which is unaffected by the magnet, falls free from the magnet into the “cleaned” flow. All ferrous tramp metal is captured by the magnetic field and is held onto the drum’s surface. As the drum rotates, the metal is carried past the diverter and released outside of the magnetic field for collection and disposal.

How a magnetic drum separator works

Features of Magnetic Drum Separators

- Powerful ceramic or rare earth magnet

- Over 180° of magnetic arc protection

- Manually adjustable magnetic arc position

- Drum diameters from 12 inches to 24 inches

- Drum widths from 12 inches to 60 inches

- Fixed diverter to separate cleaned product and the collected tramp metal

- Flex seal to prevent product from flowing around the backside of the drum

- Access doors for inspection and drum removal

- Sealed bearings for the drum supports and drive

Additional Options

- Custom diameters and widths

- Stainless steel drum shaft

- Adjustable inlet opening

- Special magnetic circuits for reach out or holding

- Stainless steel housings for ceramic drums

- Special inlet for vibratory feeder interface

- Multiple drum assemblies

- Fine particle discharge

- Custom inlet and discharge transitions

- Special voltage motors and drive packages

- Abrasion resistant facing

- Zero speed switch

Watch a Video

Ask a Question or Get a Price Quote