Automate your candy and chocolate production lines and processes!

New or existing candy and chocolate production lines can be fully automated and equipped with control systems on all processing units.

NEED HELP FAST? We have over 40 years' experience with Bulk Material Handling, Packaging, and Processing. (979) 217-1480 GET A QUOTE

NEED HELP FAST? (979) 217-1480 GET A QUOTE

Category | Automatic Bagging Machines | Bag Handling Conveyors | Bulk Bag Unloaders | Bulk Processing Equipment | High Speed Robotic Palletizers | Industrial Mixers | Open Mouth Bagging Machines | Small Bag Fillers | Small Vibratory Feeders |

Automate your candy and chocolate production lines and processes!

New or existing candy and chocolate production lines can be fully automated and equipped with control systems on all processing units.

Category | Open Mouth Bagging Machines |

This system is used for bagging salt into 40 Lb. poly bags. It includes a hopper, net weigh bagging machine, band sealer, and manual bag stacking station with pallet wrapper machine.

Category | Open Mouth Bagging Machines |

A co-op in Iowa replaced their existing bagging machine with a high-speed net-weigher used to fill 50Lb craft paper bags with cracked corn and pelleted feeds.

High-speed bagging machine added to existing packaging system

This cooperative grinds approximately 50,000+ bushels of corn per day at all of their feed mills. They primarily supply swine feed, but also produce cattle feed and dairy feed.

Category | Bulk Bag Unloaders | Open Mouth Bagging Machines |

Packaging system fills open mouth paper bags at a rate of 4-6 bags per minute with granular and powder products, such as zeolite and guar gum.

The system repackages products from big bags, also called bulk bags or Super Sacks®. It includes a forklift loaded bulk bag unloader with an extended frame to accommodate an open mouth bagging machine underneath.

Category | High Speed Robotic Palletizers | Open Mouth Bagging Machines |

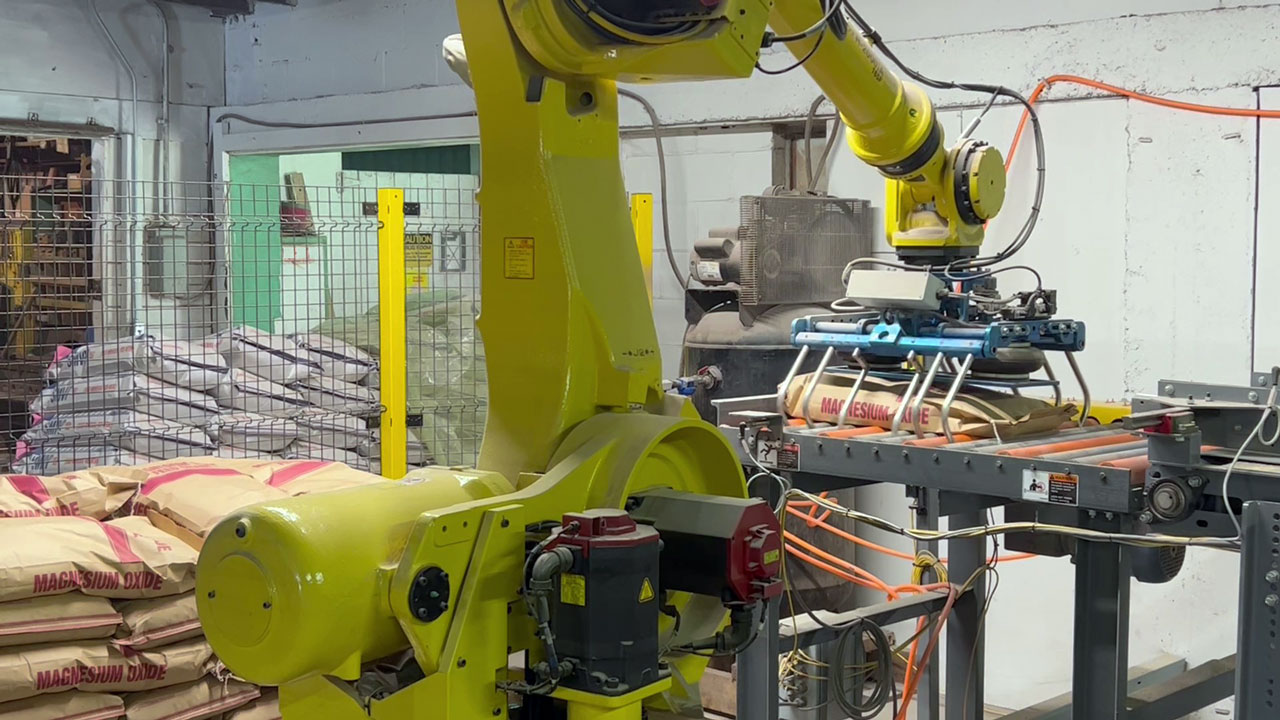

This bagging plant fills 40KG open mouth plastic bags with different types of livestock feed for poultry, pigs, dairy cows, sheep, and horses. It includes a high-speed bagging machine, bag handling conveyors, and a palletizing robot with automatic pallet dispenser and automated pallet wrapper.

Category | Bagging Equipment by Product | Open Mouth Bagging Machines |

Dry pet food bagging systems and machines automatically weigh and fill 1-50 lb. bags, pouches, containers, and multi-wall open mouth bags with different types of dry pet food. This includes dog food, cat food, rabbit food, hamster food, food for mice, and more.

Dry pet food bagging systems and machines automatically weigh and fill 1-50 lb. bags, pouches, containers, and multi-wall open mouth bags with different types of dry pet food. This includes dog food, cat food, rabbit food, hamster food, food for mice, and more.

Fill small bags, pouches, and containers that weigh 1 – 10 pounds or larger open mouth paper or poly bags that weigh 10 – 50 pounds, or bulk bags that weigh up to 4,400 pounds. All packaging machines have an accuracy of +/- 0.5-1% of target weight and can operate at different bagging speeds.

Category | Automatic Bagging Machines | Bagging Equipment by Product | Open Mouth Bagging Machines | Small Bag Fillers |

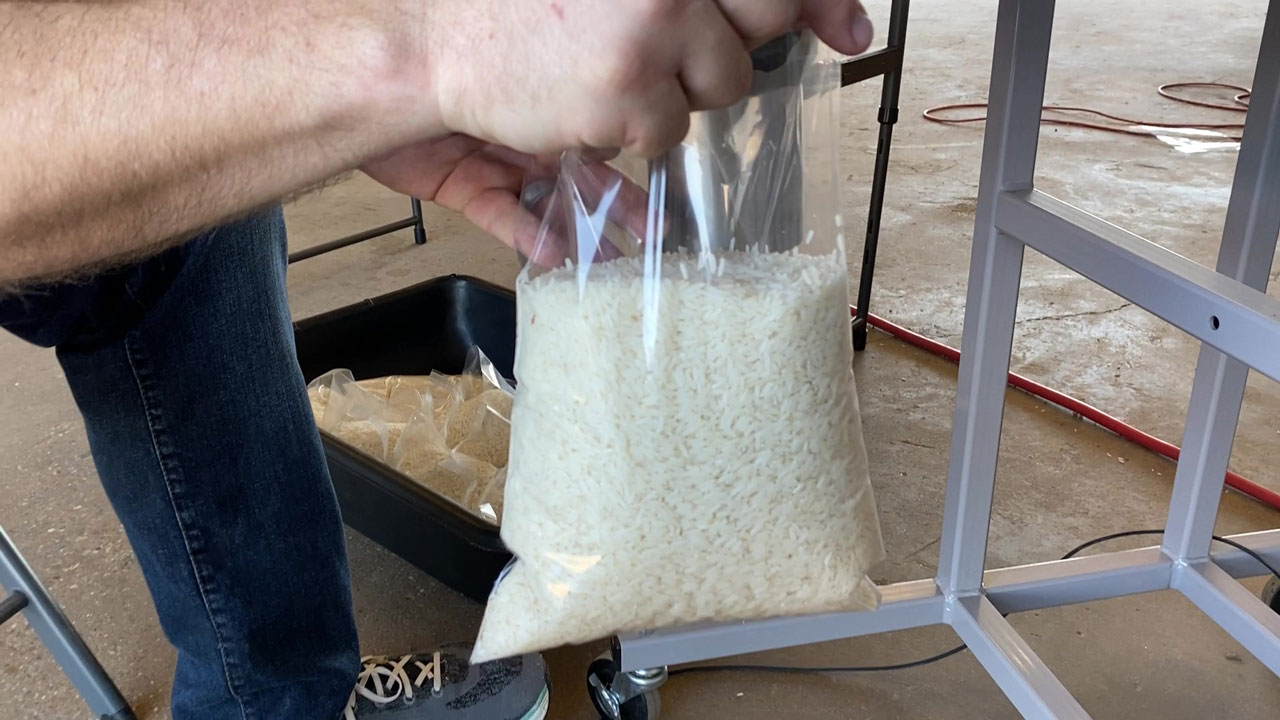

This commercial equipment is used for repackaging bulk dry goods stored in bulk bags, bins, totes, pro boxes, 40-50Lb bags, and more into small bags, pouches, and containers.

Examples of free-flowing bulk dry goods to repackage or re-bag would be food products such as rice, nuts, coffee beans, sprinkles, pasta, beans, candy, seeds, dog food, and cat food as well as products such as feed pellets, wood pellets, and plastic pellets.

Category | Automatic Bagging Machines | High Speed Robotic Palletizers | Open Mouth Bagging Machines |

This packaging and palletizing line fills craft paper bags with 25, 40, or 50 lbs. of livestock minerals and supplements. It includes a hopper, net weigh bag filling machine, high-speed bag sewing system, and robotic palletizer with 2 bag stack zones. It replaced an existing bag filling and packaging line at the feed service company that has been in business since 1946.

Category | Open Mouth Bagging Machines |

Filling 50 lb. bags with milk powder

This milk powder bag packing machine fills 50 lb. open mouth bags at a rate of 2-3 bags per minute. It provides an accurate and dust tight filling process. The machine is designed to be quickly and easily disassembled for access to internal components when cleaning and sanitation is required.

Category | Automatic Bagging Machines | Open Mouth Bagging Machines |

The video below shows an automated feed bagging system that quickly fills and packages multi-wall paper bags with 50lbs. of alfalfa pellets (pasture cubes or range cubes) to be used for livestock feed. This system uses a high-speed net weigh bagger with 2 internal weigh hoppers.

Category | Automatic Bagging Machines | Bag Handling Conveyors | Bag Sewing Machines and Heat Sealers | High Speed Robotic Palletizers | Open Mouth Bagging Machines |

This automated packaging and palletizing system is designed to fill 20-110 lb. open mouth poly bags at a rate of 10 bags per minute or more. Free-flowing and dry bulk material flows from the 80 cu. ft. hopper into a net weigh gravity flow bagging scale that includes a vibrating feeder with a gravity gate. The feeder doses a set amount of product into the internal weigh hopper of the bagging scale.

Category | Open Mouth Bagging Machines |

This aggregate bagging plant fills multiwall paper bags (also known as open top, 25kg kraft paper bags) with aggregate and crushed rock at a rate of 10 bags per minute. The plant also includes a dust collection system. The customer is adding a robotic palletizer to further automate the packaging process.

Category | Bagging Equipment by Product | Bulk Bag Fillers | Open Mouth Bagging Machines | Small Bag Fillers |

Choose from different types of seed bagging equipment to package seeds and grains into small bags, pouches, 50 lb. bags, and all the way up to 4,400 pound bulk bags. All machines have an accuracy of +/- 0.5-1% of target weight and can operate at different fill rates.

Fill bags with many different types of seeds and agricultural products such as soybean seeds

This type of equipment fills bags with many different types of agricultural products such as seeds and grains. This includes sunflower seeds, grass seeds, wheat seeds, corn seed, soybean seeds, barley, oats, rice, bird seed, alfalfa, rye, canola, and more.

Category | Automatic Bagging Machines | Bulk Bag Fillers | Open Mouth Bagging Machines | Small Bag Fillers | Valve Bag Fillers |

There are many different types of bagging machines using custom configurations to package many types of products. These products can range from agricultural products like corn, feed, and seed to chemical and industrial powders like graphite, gypsum, and barite.

There are many different types of bagging machines using custom configurations to package many types of products. These products can range from agricultural products like corn, feed, and seed to chemical and industrial powders like graphite, gypsum, and barite.

Since 1978, we have seen it all!