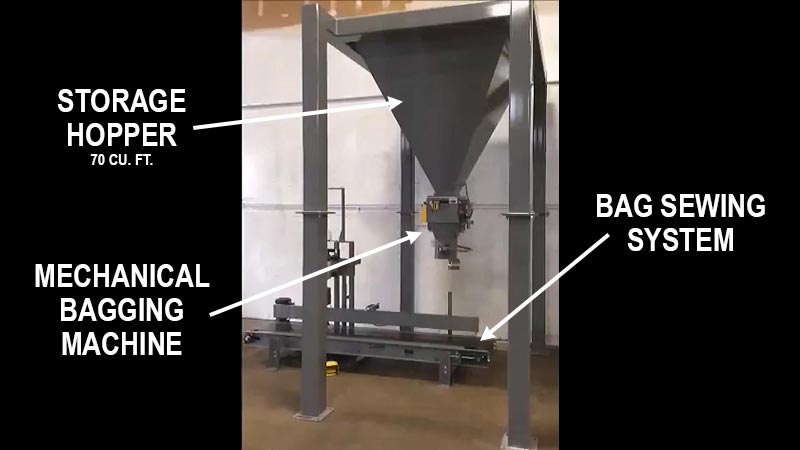

Use professionally manufactured feed bagging equipment and systems to fill 20-110 lb. paper or plastic open mouth bags (50lb. bags being the most popular) with many different types of feed. Buy just the feed bagger or an entire bagging system that includes a 25-100 cu. ft. storage hopper, feed bagger, bag conveyors, bag sewing machine, palletizer, and more.

Use professionally manufactured feed bagging equipment and systems to fill 20-110 lb. paper or plastic open mouth bags (50lb. bags being the most popular) with many different types of feed. Buy just the feed bagger or an entire bagging system that includes a 25-100 cu. ft. storage hopper, feed bagger, bag conveyors, bag sewing machine, palletizer, and more.

Need an automatic bagging machine or system for faster bagging and palletizing?

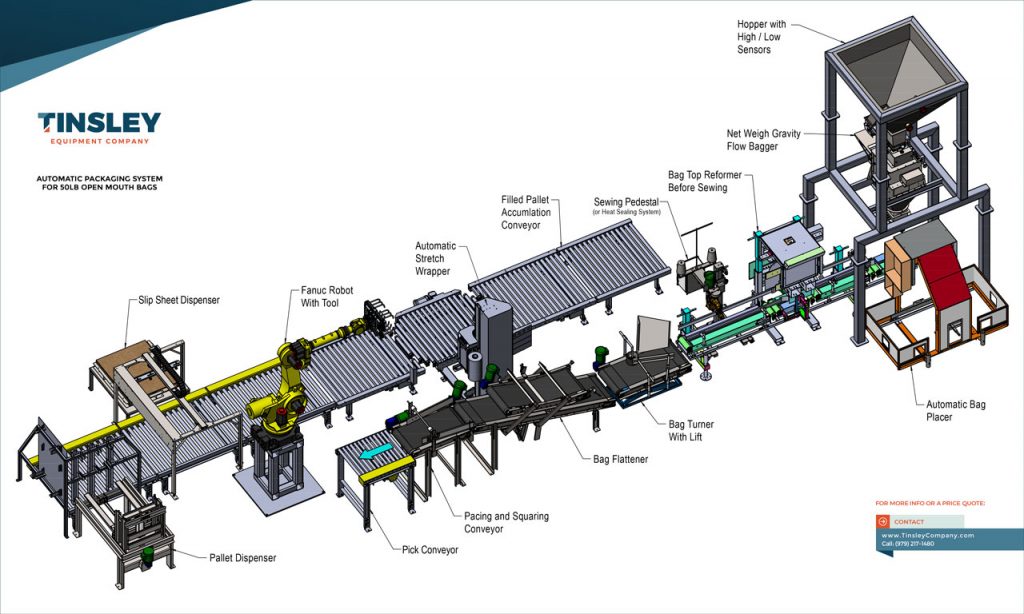

We can also provide an automatic bagging machine or system to fit existing bagging operations including a high-speed net weigh bagger, industrial bag handling conveyors, robotic palletizers, and more.

Jump to a section below:

- Manual Feed Bagging (4-6 bags per minute)

- Semi-Automatic Animal Feed Bagging (10-12 bags per minute)

- Fully-Automatic Animal Feed Bagging System (15-18+ bags per minute)

Ask a Question -or- Get a Price Quote

1. Manual Feed Bagging Machines (4-6 bags per minute)

- Engineered for bagging many different types of free-flowing animal feed – livestock feed, cattle feed, deer corn, horse feed, hunting feed, bird feed, feed additives, and more

- Lower cost, manual mechanical gross weight bagging scale – allows one operator to fill up to 6 bags per minute to a typical scale weight accuracy of +/- 1% target weight.

- Increase production and fill accuracy – using a digital scale bagging machine with a typical scale weight accuracy of +/- 0.5% to 1% target weight.

- 25-87 cubic foot bagger supply hoppers with integrated scale supports – professionally manufactured, high-strength, and 2-part epoxy coated hoppers that work seamlessly with bagging equipment.

- Bag sewing systems – a single operator sews bags on an 8 ft. long conveyor with pedestal mounted bag sewing machine.

- In the future, this type of bagging system can be upgraded – with a high-speed bag sewing system, robotic palletizer, and automated pallet wrappers for even higher rates of packaging.

- Do you use bulk bags or a pro box / bin to store feed? – use a big bag unloader to supply your baggers or hoppers. We also manufacture a Buckhorn Pro Box bin discharge stand that works seamlessly with these bagging machines.

2. Semi-Automatic Feed Bagging Machines (10-12 bags per minute)

- 50-200 cubic foot capacity hoppers and scale supports – store more feed for faster bagging rates!

- High-speed net weigh bagger – feed is automatically loaded into an internal weigh hopper while a bag is being filled below, thus increasing bag fill rates

- Bagging sticky feeds? – use a belt-fed gross weigh bagger. For bagging powders and feed additives, we recommend an auger fed bagger.

- In this type of bagging system, an operator manually places a bag on the machine’s spout – a pneumatic bag clamp engages and holds the bag on the spout during filling. Add an automatic bag placing machine to increase automation and further reduce labor costs.

- High-speed bag sewing system – after filling, the bag drops onto a closing conveyor and travels through a bag sewer

- Bag conveyors – after sewing the bag is “knocked down”, travels through a bag flattener, and then onto a palletizing conveyor

- Palletizing – flattened bags are manually palletized by an operator(s) or with a semi-automatic robotic palletizing system

Watch a Video

This video shows an automated feed bagging system. Even though the system has a high-speed bagger and automatic bag hanger, it falls under the “semi-automatic” category because palletizing is done manually by multiple operators at the end of the bagging line.

3. Fully-Automatic Feed Bagging System (15-18 bags per minute)

Top section of hopper and belt fed high-speed bagger for sticky animal feeds

- 80-200 cu. ft. hoppers – store more feed for faster bagging rates

- High-speed net weigh bagger – feed is automatically loaded into dual internal weigh hoppers while a bag is being filled below.

- Bagging sticky feeds? – use a belt-fed bagger. For bagging powders and feed additives, we recommend an auger fed bagger.

- Automatic bag hanger – a robot picks up empty bags, opens them, and places them on the bagger’s spout

- High-speed bag sewing system – the bagger drops the filled bags onto a closing conveyor, where they travel through a high-speed bag sewing system

- Bag conveyors – after sewing, bags are “knocked down”, travel through a bag flattener, and then onto a robot pick conveyor.

- Fully-automatic palletizing system – with pallet dispenser, stretch wrapper, and bag palletizing robot

Whether you are bagging livestock feed, bird seed, horse feed, or feed additives, we can provide the right equipment and system for your animal feed bagging business. These baggers and systems consistently and accurately fill 50lb. bags with many different types of animal feed. Automated bagging machines and equipment can provide the quickest return on your investment and can be operated by a few number of employees with very little training.

Ready to upgrade or enhance your Feed Bagging business?

Need pricing fast or have a question?

Use this express contact form! A Tinsley Equipment Company sales engineer will email you current pricing for all equipment and system components listed on this page usually within 24 hours or less. Need to speak with someone? Call: (979) 217-1480

* All fields are required.