This packaging system unloads granulated sugar from bulk bags and repackages it into 50 Lb. paper valve bags before metal detection and palletizing.

NEED HELP FAST? We have over 40 years' experience with Bulk Material Handling, Packaging, and Processing. (979) 217-1480 GET A QUOTE

NEED HELP FAST? (979) 217-1480 GET A QUOTE

Category | Valve Bag Fillers |

This packaging system unloads granulated sugar from bulk bags and repackages it into 50 Lb. paper valve bags before metal detection and palletizing.

Category | Valve Bag Fillers |

Bag of pigment powder tipping onto discharge conveyor after filling

This semi-automatic system fills batch inclusion bags with blended pigment powders used for road markings. After filling, the bags are conveyed to a palletizing station.

Blended pigment powder used for road marking is conveyed to a bucket elevator that discharges it into a 25 cubic foot hopper. Then, the powder flows by gravity into the air chamber of the valve bag air packer.

Category | Automatic Bagging Machines | Bag Sewing Machines and Heat Sealers |

This machine automatically reforms or prepares the top of flat, pillow type open mouth bags and guides them into the infeed of a high-speed bag closer or sewing machine.

Bag moves through a bag top reformer before sewing

This type of automation can eliminate the need for an operator to manually guide a filled bag into a bag closing system. It can handle production rates up to 15 bags per minute and typically comes with an automatic bag placer.

Category | Automatic Bagging Machines | High Speed Robotic Palletizers |

Automatic pallet dispenser, slip sheet applicator, and robot stack zone conveyor (System 1)

When speed and bagging rate is important, automating the dispensing of pallets and slip sheets helps to reduce labor requirements for feeding shipping pallets into an automated palletizing system with a robot.

Category | Bulk Bag Unloaders | Open Mouth Bagging Machines |

Packaging system fills open mouth paper bags at a rate of 4-6 bags per minute with granular and powder products, such as zeolite and guar gum.

The system repackages products from big bags, also called bulk bags or Super Sacks®. It includes a forklift loaded bulk bag unloader with an extended frame to accommodate an open mouth bagging machine underneath.

Category | High Speed Robotic Palletizers | Open Mouth Bagging Machines |

This bagging plant fills 40KG open mouth plastic bags with different types of livestock feed for poultry, pigs, dairy cows, sheep, and horses. It includes a high-speed bagging machine, bag handling conveyors, and a palletizing robot with automatic pallet dispenser and automated pallet wrapper.

Category | Bagging Equipment by Product | Open Mouth Bagging Machines |

Dry pet food bagging systems and machines automatically weigh and fill 1-50 lb. bags, pouches, containers, and multi-wall open mouth bags with different types of dry pet food. This includes dog food, cat food, rabbit food, hamster food, food for mice, and more.

Dry pet food bagging systems and machines automatically weigh and fill 1-50 lb. bags, pouches, containers, and multi-wall open mouth bags with different types of dry pet food. This includes dog food, cat food, rabbit food, hamster food, food for mice, and more.

Fill small bags, pouches, and containers that weigh 1 – 10 pounds or larger open mouth paper or poly bags that weigh 10 – 50 pounds, or bulk bags that weigh up to 4,400 pounds. All packaging machines have an accuracy of +/- 0.5-1% of target weight and can operate at different bagging speeds.

Category | Automatic Bagging Machines | Bagging Equipment by Product | Open Mouth Bagging Machines | Small Bag Fillers |

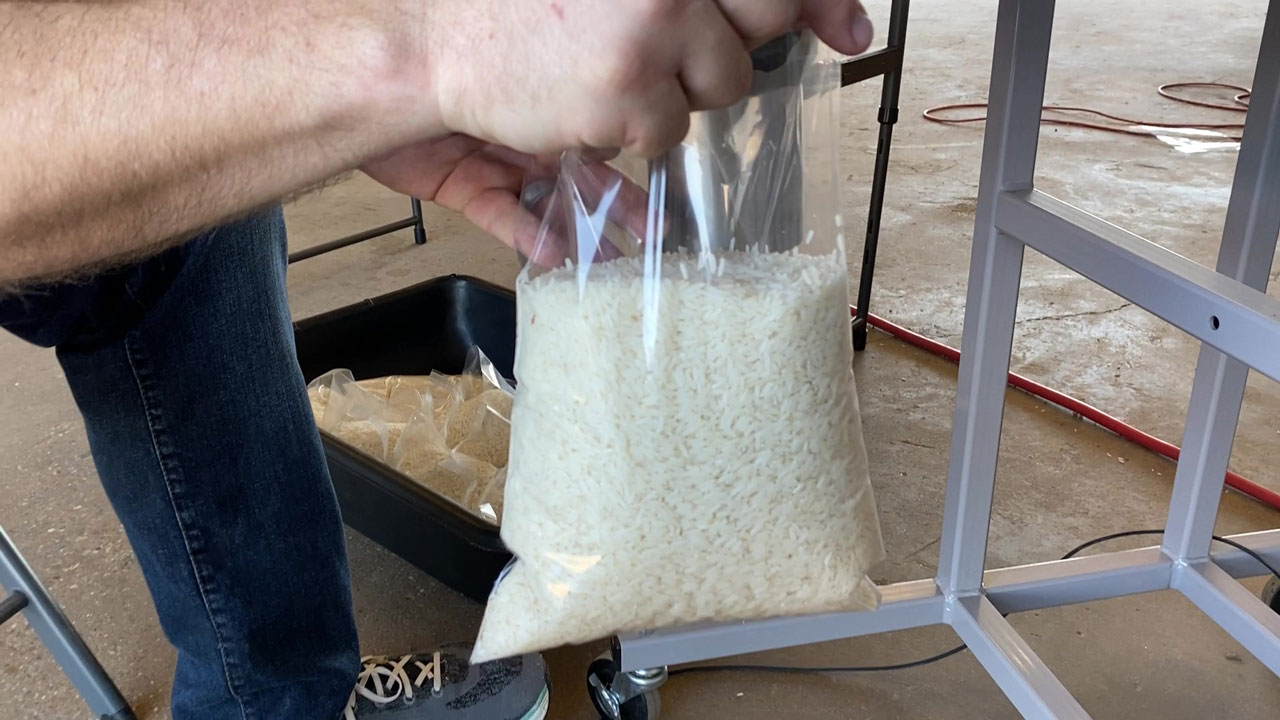

This commercial equipment is used for repackaging bulk dry goods stored in bulk bags, bins, totes, pro boxes, 40-50Lb bags, and more into small bags, pouches, and containers.

Examples of free-flowing bulk dry goods to repackage or re-bag would be food products such as rice, nuts, coffee beans, sprinkles, pasta, beans, candy, seeds, dog food, and cat food as well as products such as feed pellets, wood pellets, and plastic pellets.

Category | Automatic Bagging Machines | High Speed Robotic Palletizers | Open Mouth Bagging Machines |

This packaging and palletizing line fills craft paper bags with 25, 40, or 50 lbs. of livestock minerals and supplements. It includes a hopper, net weigh bag filling machine, high-speed bag sewing system, and robotic palletizer with 2 bag stack zones. It replaced an existing bag filling and packaging line at the feed service company that has been in business since 1946.

Category | Bagging Equipment by Product |

Choose from different types of rice bagging equipment to package rice and other grains into small bags, pouches, larger 50 Lb. bags, and all the way up to 4,400 Lb. bulk bags. All bagging machines have an accuracy of +/- 0.5-1% of target weight and can operate at different fill rates depending on your packaging line requirements.

Rice bagging equipment fills small to very large bags with rice

Category | Food Seasoning and Coating |

Electrostatic seasoning systems evenly coat food and pharmaceutical products with seasonings and flavorings. Apply 15-45% less powders, flavors, coatings, vitamins, spices, and oils to a wide range of products. Design and implement a complete system that is manufactured to food-grade industry standards.

Try before you buy! Product testing is available.

Call: (979) 217-1480 -or- use our Express Contact Form to ask a question or get price quote.

Category | Automatic Bagging Machines | High Speed Robotic Palletizers | Valve Bag Fillers |

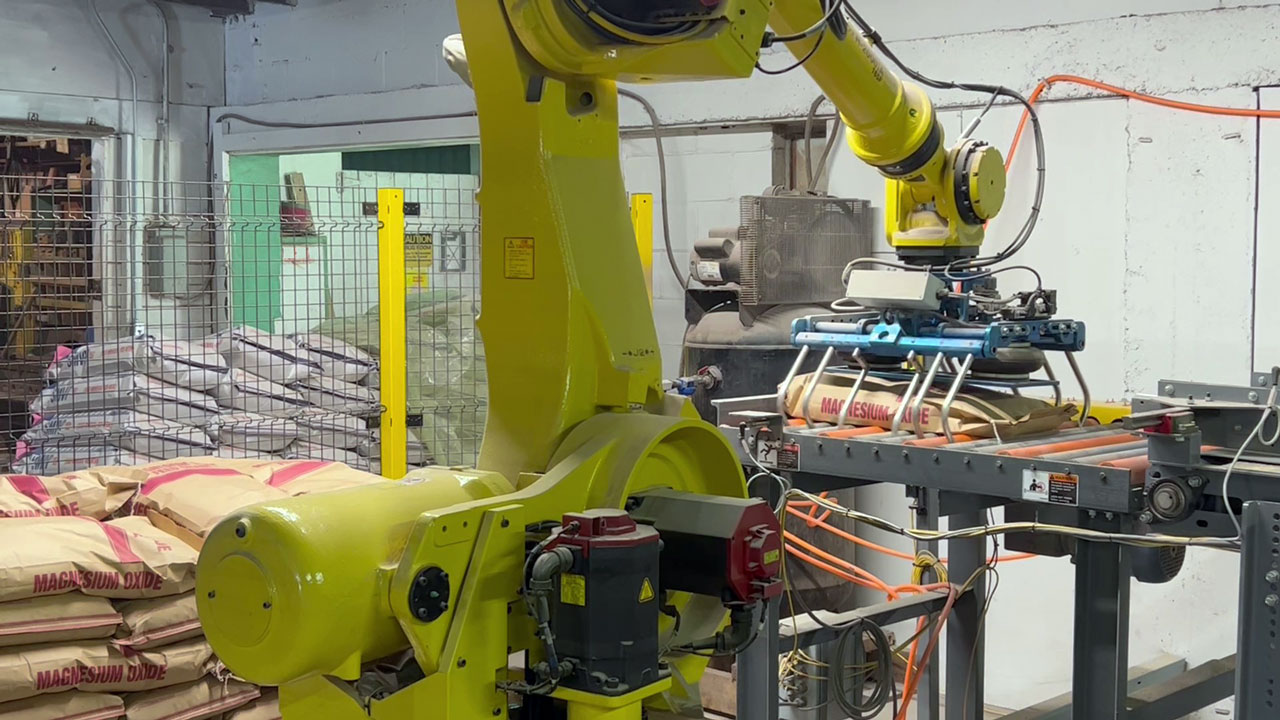

End-of-line robot picking up 100 lb. bag of minerals using a bag gripper tool

A contract packaging company recently added an end-of-line robot to their existing valve bag filling system. The new robotic palletizing system includes bag handling and robotic pick conveyors, a used Fanuc robotic arm that has been reconditioned with a bag gripper tool, and an automated pallet and slip sheet dispenser.

With the added palletizing automation, the entire system is now able to fill and stack 100 lb. paper valve bags at a rate of 10-12 bags/minute. The company can also quickly swap out settings to fill and stack 50 lb. valve bags at a rate of 15-16 bags/minute.

Category | Automatic Bagging Machines | Bulk Processing Equipment |

Use an automated bagging system to fill boxes and baler bags with small pre-packaged, form fill and seal (FFS) bags or pouches containing products such as grains, sugar, flour, salt, powders, and more. This type of automation can enhance your end of line packaging and provide a more convenient way to ship and handle smaller bags together as a stackable unit.

Use an automated bagging system to fill boxes and baler bags with small pre-packaged, form fill and seal (FFS) bags or pouches containing products such as grains, sugar, flour, salt, powders, and more. This type of automation can enhance your end of line packaging and provide a more convenient way to ship and handle smaller bags together as a stackable unit.

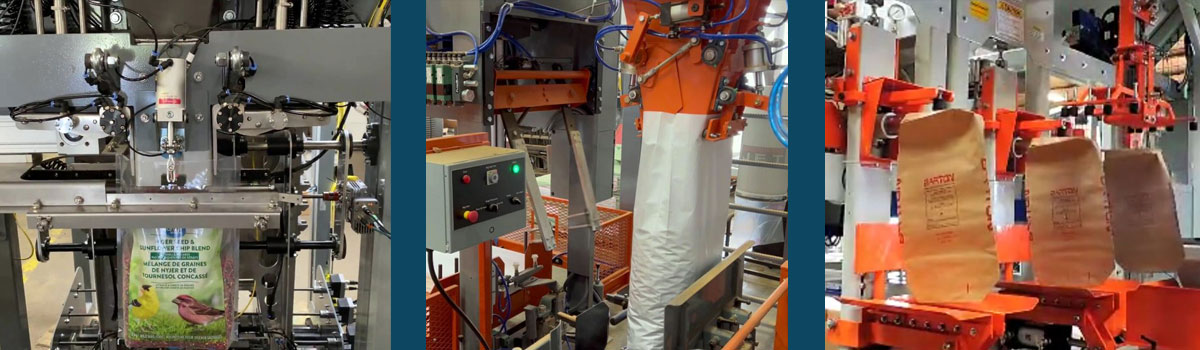

Category | Automatic Bagging Machines |

Automatic bagging systems for pouches, open mouth bags, and valve bags

Automatic bagging systems are typically used to fill and seal bags and pouches containing 1-110 lbs. of product. The systems can be categorized by the types of bags or pouches being filled.