An Intermediate Bulk Container (IBC) System is used to prepare a homogeneous dry blend of base polymers and additives before the extrusion phase in a plastic compounding process. Plastic compounding and toll processing companies first use an IBC system to create a lab formulation or test to confirm final product characteristics before creating a masterbatch. Once a final product has been confirmed, the same IBC system is used to create a larger batch or production run.

IBC is easily transported by forklift to other discharge stations

This type of set up using an Intermediate Bulk Container (IBC) System is also known as a decoupled system because ingredients can be moved, mixed, and blended independently inside the IBCs.

Plastic Compounding Process Overview

Polyethylene and polypropylene base polymers are added to an empty IBC container. Next, powder, flakes, or small pellet modifiers are added to the base polymers. Multiple additives and transformers give the final plastic product a specific strength, texture, color, etc. specified by the customer or to conform to SO 13485 certification to manufacture compounds for medical device applications.

Filling an Intermediate Bulk Container IBC with base polymers, additives, and transformers

All these raw materials can be added to a stainless steel IBC container using a dump station or by dosing precise amounts of ingredients from various bulk bag or discharge stations located throughout the Intermediate Bulk Container IBC System.

The raw materials are mixed and blended inside of the IBC container using a tumble blender. This reduces the number of product transfers and creates a homogenous dry blend. After blending and mixing, the stainless steel IBC container is transported to a discharge station using a forklift, where it will be used as a refill bin or hopper to feed an extruder.

IBC inside of tumble blender

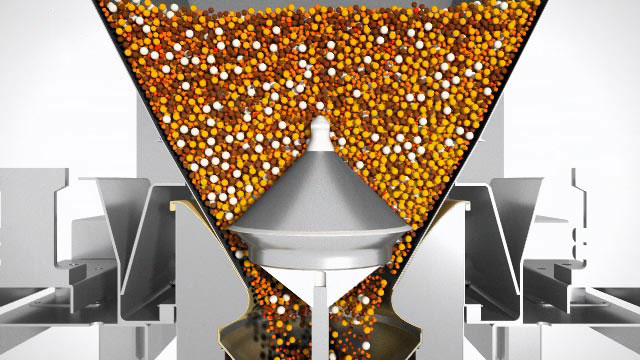

As the IBC is lowered onto the discharge station, the IBC outlet automatically engages into the station’s top line and the IBC’s cone valve locates onto the station’s central probe. This creates a dust tight seal between the IBC and discharge station. The actuator in the discharge station lifts the cone valve inside the stainless steel IBC container to accurately discharge the plastic compounds in such a way as to avoid bridging, rat-holing, and segregation that happens with traditional slide gate or butterfly valves.

The extruder produces noodle-like strands of plastic that are cut to produce the final plastic pellet product. The pellets are packaged into open mouth bags, bulk bags, or octabins / bulk boxes and placed on a pallet for storage, shipping, or resale.

Lowering an IBC onto a demonstration discharge stand

Cone valve inside of stainless steel IBC container

Cut away 3D view of cone valve inside ibc container

Watch a Video Demonstration

Learn more about IBC blending, batching, or mixing and stainless steel IBC containers.

Ask a question or get a price quote.

Call: (979) 217-1480