Blend metal powders evenly inside a stainless steel intermediate bulk container.

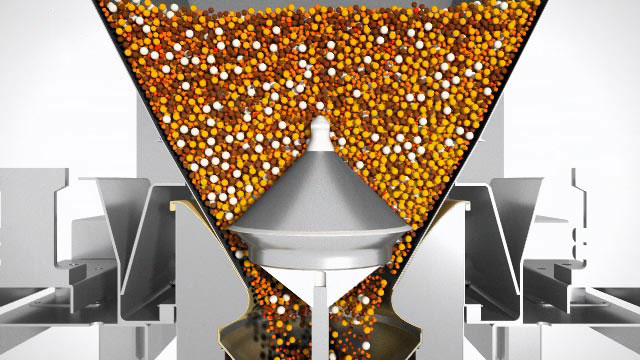

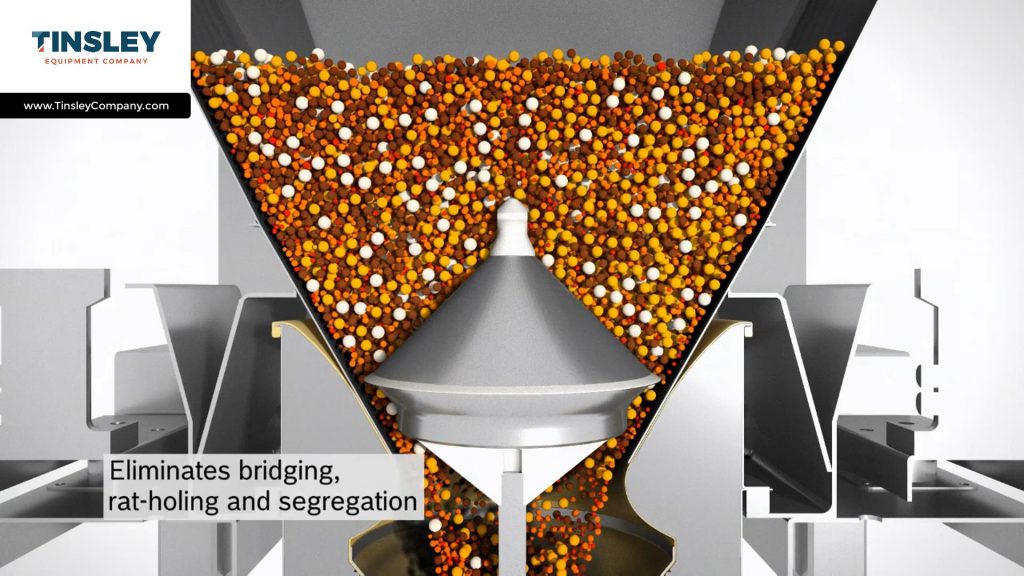

Prevent powder bridging, rat holing, or segregation with a cone valve that is integrated into the bottom of each IBC container!

Stainless steel intermediate bulk containers and IBC blending systems are a special type of custom blending equipment that are widely used in various industries for their durability and functionality in bulk powder processing. These containers are designed to store and transport large volumes of powders, liquids, and granules in a safe and secure manner.

These types of powder blending systems are constructed using high-quality finished stainless steel, making them strong, corrosion-resistant, and easy-to-clean. They are available in various sizes and shapes and can be custom designed to fit specific metal powder handling requirements. Stainless steel IBC containers and systems are a popular choice for industries that require powder mixing solutions for the bulk processing of powders, such as powder metallurgy, chemical, pharmaceutical, nutraceutical, toll blending, and food industries.

Metal Powder Blending Solutions

This custom blending equipment provides excellent powder blending solutions for metallurgy businesses and toll blending companies. Some of the key benefits of using these centerflow containers include:

- Efficient and reliable packaging and storage of powders and granules transferred from equipment such as bulk bag unloaders, other IBC blending equipment, IBC discharge systems, pneumatic conveyors, and 50 pound bag dumpers

- Lower costs of handling and improved safety

- Increased efficiency in transporting of bulk powders

- Custom blending solutions can be designed to mix metal powders evenly inside an IBC

- Multiple inlet and outlet ports, variable frequency drives for agitators, and other accessories can be incorporated to ensure proper blending, mixing, and handling of powders

Stainless steel IBC containers and systems are an ideal choice for material handling of bulk powders in various industries.

Watch a Video:

Powder Mixing and Blending

Stainless steel intermediate bulk containers and systems are excellent for mixing and blending powders. The process of mixing powders inside of IBC containers is efficient and reliable.

With their conical-shaped, centerflow container design, dead zones are minimized and the potential for powder bridging, rat holing, caking, or segregation is greatly reduced. Agitators can also be incorporated into IBC blending systems to ensure uniform mixing of powders. In addition, IBC containers and systems offer the ability to mix and blend powders on a large scale, which can be cost-effective for manufacturers.

Cut away 3D view of a cone valve inside a stainless steel intermediate bulk container

Metal powder blending and mixing can be done in batches or continuously. Batches are mixed inside the IBC container, while continuous blending is done using external equipment that connects to the IBC system. The IBC containers for powders can be used as intermediate containers between multiple pieces of blending equipment, allowing for more efficient powder processing.

Tumble blending is a specialized method of agitating powders inside of an IBC container to create a consistent blend and mix. This is achieved by placing the IBC container, which contains all of the ingredients, inside of a tumbling blender. This type of custom blending equipment is designed to rotate and lift the IBC container in a specific way that ensures that the powders are evenly blended.

Mix powders evenly inside an IBC using a tumbling blender

Tumbling blenders are available in different sizes and designs, allowing them to accommodate the size and shape of each intermediate bulk container. Tumbling of powder achieves a consistent blend and mix without the need for additional powder mixing solutions. This saves time, space, and reduces the risk of damage or segregation during the mixing process.

Tumble blending is especially beneficial for delicate powders that require gentle mixing. This method of blending minimizes the risk of segregation, clumping, and other issues that can arise when using other types of mixing equipment.

Intermediate Containers

Intermediate containers can be used with IBC blending systems to improve the efficiency of metal powder processing. This type of custom blending equipment is used to store and transport powders in between processing steps, providing a secure and easy-to-handle solution.

Metal powder stored in a stainless steel IBC being transported to an IBC discharge system

The use of intermediate containers with IBC bulk handling systems have several advantages. They can be used to store powders for an extended periods of time, reducing the number of times the IBC container is filled and emptied. Intermediate containers can also be used to supply multiple processing lines, reducing the need for additional containers.

Intermediate containers can be made from various materials, such as plastic or stainless steel, and can be designed to meet specific requirements, such as aseptic or sterile applications. The use of intermediate containers can significantly improve the efficiency of powder processing and handling while reducing the risk of contamination in sensitive industries such as pharmaceuticals and food.

IBC Bulk Handling System for Powder Mixing and Custom Blending

Types of Intermediate Bulk Containers

Stainless steel bins for the powder metallurgy industry come in various types to meet custom requirements. Two of the most common types are also stackable and stainless steel.

Stainless steel powder containers

Stackable stainless steel bins are designed to save space during storage and transportation. These bins can be stacked one on top of the other, reducing the amount of floor space needed for storage. They are ideal for industries that require a large number of IBC containers for a large powder blending system.

IBC Discharge Systems

Discharging powders from stainless steel IBC containers is an essential step in a powder blending system. There are various types of IBC discharge systems available, including manual, vibratory, and pneumatic. Each of these can range from manual to a fully automated IBC discharge system. However, the most efficient and reliable discharge method is through the use of a cone valve.

A cone valve is a hygienic valve that can be incorporated into the bottom of the IBC container. The valve operates using gravity and air pressure to discharge powder from a container. Cone valves are beneficial in that they provide a powder bridging solution and can prevent powders from rat holing, or segregating, which can cause significant issues in downstream blending and packaging equipment.

Cone valves can be used with a range of downstream bulk handling equipment, including feeders, loss-in-weight feeders, and other types of bulk processing equipment. The discharge process is highly accurate and can be customized to meet specific material handling requirements.

Intermediate bulk container being lowered onto a IBC discharge system

Conclusion

Stainless steel intermediate bulk containers and custom blending equipment offer many benefits for industries that require bulk metal powder processing. With their durability, functionality, and cost-effectiveness, these containers and systems are a popular choice for powder metallurgy, chemical, pharmaceutical, toll blending, and food industries.

If you’re interested in learning more about this type of processing and blending equipment, contact us today to speak with one of our sales engineers. We can help you find the right powder blending (or bridging) solutions and provide expert advice on custom material processing solutions.

Ask a question -or- Get a Price Quote

Call: (979) 217-1480