Coating and seasoning cashews with a dill pickle seasoning

This system is used for seasoning and coating nuts using electrostatics. The customer was able to produce seasoned nut and seed food products in one day instead of seven. It also greatly reduced production costs associated with the previous system, providing a quick ROI. It can be retrofitted to existing seasoning equipment and systems.

On-site testing is available to prove actual production results. Please contact us for more information.

Apply many different types of seasonings such as ranch, bacon ranch, salt and pepper, parmesan and pepper, buffalo flavored, BBQ, cinnamon, churro flavored, salt and vinegar, sweet and salty, dill pickle, and wasabi. These types of custom seasonings can be applied to nuts, seeds, popcorn, cheese, chips, and other snack food products.

Dill pickle seasoning being applied to cashews using an electrostatic coating process

Background Information

An American-based snack food producer selected a continuous flow seasoning system for use at their nut processing facility to increase the production rate of seasoned nut and seed products. This new system increases production, while allowing for flexibility in production rates needed for different types of nuts and custom seasoning combinations. Included in this system is an electrostatic coating technology for both liquid and dry seasonings to ensure an evenly coated finished product.

Watch a Video

Infeed System for Raw Nuts and Seeds

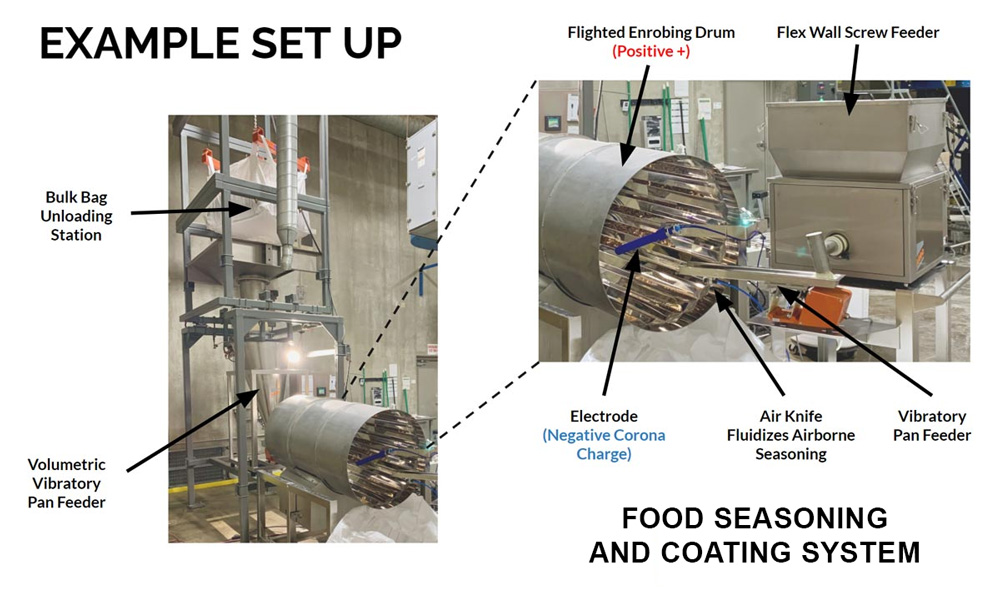

For the initial test, raw cashews were unloaded from a bulk bag unloading station into a volumetric vibratory pan feeder. This type of feeder has an adjustable feed rate controller that can be manually adjusted to increase or decrease the discharge rate of the raw nuts or seeds into the enrobing drum (also called a tumbler, tumbling drum, seasoning drum, or coating drum).

Volumetric feeder doses raw cashews into the enrobing drum

Enrobing Drum

A continuous flighted enrobing drum with a 24” diameter gently turns the cashews, while dill pickle seasoning is applied. The continuous flighting of the drum allows for an effective but gentle tumbling of the nuts or seeds. A variable speed drive is supplied to control the rotating speed of the drum for flexibility with different snack food products.

Liquid Seasoning Electrostatic Coating

A peristaltic pump supplies liquid seasoning to the electrostatic spray nozzle assembly. The liquid seasoning is sprayed into a negatively charged electrostatic field towards the drum wall with nuts or seeds. The drum is grounded causing the attraction of the fine spray mist particles onto the surface of the seeds or nuts. This also reduces the amount of over spray that might otherwise escape the drum and settle onto the surrounding area.

Electrostatic spray nozzle applies liquid seasoning to nuts and seeds

Dry Seasoning Coating System with Electrostatics

The dry seasoning system consists of a flex wall screw feeder, vibratory pan feeder, fluidizing air system, and electrostatic probe. In the test, dill pickle seasoning is loaded from bags into the flex-wall screw feeder.

Walls of lower hopper flex and dispense dry seasoning into pan feeder

The feeder allows for consistent feed of poor flowing seasonings and powders. As the walls of the lower hopper flex, the variable rate screw feeder will dispense or discharge dry seasoning ingredients onto the vibratory pan feeder.

Vibratory feeder doses powder seasoning into the enrobing drum

The feeder pan spreads out the seasoning across the width of the pan and conveys it toward the drum. As the seasoning is discharged off the vibratory pan, an air knife will fluidize the airborne seasoning as it enters the electrostatic field. The seasoning is attracted toward the cashews tumbling in the grounded drum.

Packaging, Bagging, or Storing

The finished product is ready for packaging at this point. This system can directly feed the bag filling machines, or the product can be stored in stainless steel IBC bins for later packaging and mixing of products.

Dill pickle cashews dispense into bulk bag for storage

Dramatic Reduction in Seasoning Powder Volume and Dust

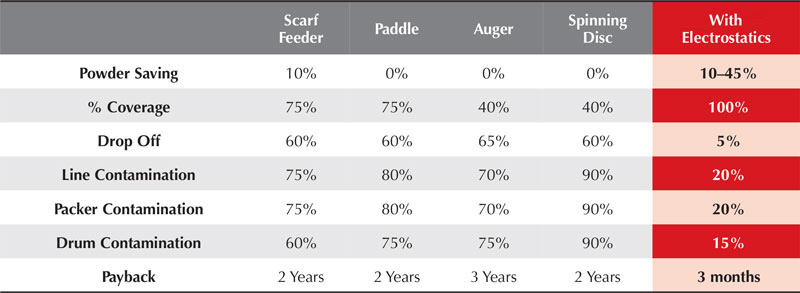

This technology is a proven solution for the dramatic reduction in seasoning volume while also reducing airborne dust for seasoning and coating nuts.

Ask a Question or Get a Price Quote