Automate your candy and chocolate production lines and processes!

New or existing candy and chocolate production lines can be fully automated and equipped with control systems on all processing units.

NEED HELP FAST? We have over 40 years' experience with Bulk Material Handling, Packaging, and Processing. (979) 217-1480 GET A QUOTE

NEED HELP FAST? (979) 217-1480 GET A QUOTE

Bulk bag unloaders (also called super sack unloaders or bulk bag dispensers) are used for material transfer from large bulk bags to industrial processing equipment or downstream bagging machines. These bulk bag unloaders are capable of supporting many different bag weights, usually in the range of 2,000 to 4,000 pounds, using heavy duty unloading frames with bag hoists. Some types of unloaders also include bulk bag conditioners (or bulk bag massagers) that promote material flow from the bulk bag.

Once the bulk bag has been lifted into place, an operator opens the access door to untie the spout and feed it into a bulk bag dispenser valve for dust-free unloading. Then the operator can unload, dispense, and discharge material to valve bag fillers, open mouth bag fillers, mixers, blenders, feeders, and more. The entire process can range from manual to fully automatic systems with multiple dump stations or portable bulk bag unloaders.

All bulk bag unloaders and frames can be custom built to your requirements and budget. Some features include a bag transport frame, a self-contained hoist for lifting, bag untie hopper, dust-tight bag seals, bag spout spikes, bag agitation paddles, bulk bag dispenser valves, and more. Save time, money, and space with dust-free unloaders and dispensers available in unlimited configurations.

Ask a question or Get a Price Quote. Use our Express Contact Form or call: (979) 217-1480

Category | Automatic Bagging Machines | Bag Handling Conveyors | Bulk Bag Unloaders | Bulk Processing Equipment | High Speed Robotic Palletizers | Industrial Mixers | Open Mouth Bagging Machines | Small Bag Fillers | Small Vibratory Feeders |

Automate your candy and chocolate production lines and processes!

New or existing candy and chocolate production lines can be fully automated and equipped with control systems on all processing units.

Category | Bulk Bag Unloaders | Open Mouth Bagging Machines |

This simple system is used to safely unload bulk feed tote bags (also called FIBC, bulk bags, Super Sacks®, or jumbo sacks) containing dry, free-flowing products by gravity into an open mouth bagging machine and scale. The bagging machine would then weigh out a desired amount of feed into each open mouth bag, with 40lb. and 50lb. bags being the most popular. This system is custom engineered for repackaging and down packing businesses.

This simple system is used to safely unload bulk feed tote bags (also called FIBC, bulk bags, Super Sacks®, or jumbo sacks) containing dry, free-flowing products by gravity into an open mouth bagging machine and scale. The bagging machine would then weigh out a desired amount of feed into each open mouth bag, with 40lb. and 50lb. bags being the most popular. This system is custom engineered for repackaging and down packing businesses.

Category | Bulk Bag Fillers | Bulk Bag Unloaders | Bulk Processing Equipment |

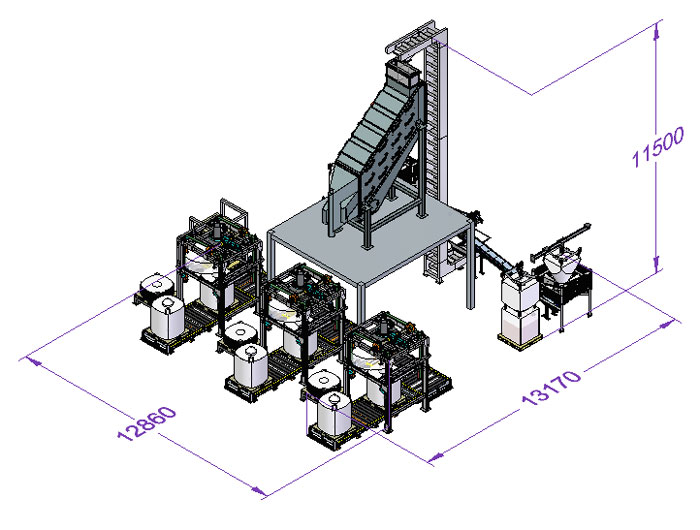

Drawing of a high-speed big bag filling system. Measurements are in millimeters.

In this hi-speed big bag filling system, raw sugar is unloaded from big bags, or bulk tote bags, conveyed to a vibratory screen where it is separated into 3 fractions and one waste fraction, and then re-packaged into big bags.

Category | Bulk Bag Unloaders | Open Mouth Bagging Machines |

Packaging system fills open mouth paper bags at a rate of 4-6 bags per minute with granular and powder products, such as zeolite and guar gum.

The system repackages products from big bags, also called bulk bags or Super Sacks®. It includes a forklift loaded bulk bag unloader with an extended frame to accommodate an open mouth bagging machine underneath.

Category | Bulk Bag Unloaders |

This portable bulk bag unloader has an overhead rail, powered trolley and hoist, and a bag lifting frame. It has been designed for a typical 4,000 pound bulk bag with bottom discharge. The unloader can be moved in the process area to allow for unloading of bulk bags at mixing or batching stations. Locking casters prevent the unit from moving while dispensing.

It can be supplied with an untie hopper and discharge spout for discharging into industrial mixers or IBC blending bins.

Stainless steel or carbon steel construction is available.

Ask a Question or Get a Price Quote

Category | Bulk Bag Unloaders | Valve Bag Fillers |

This system unloads and transfers fine powder from a bulk bag and conveys it to a valve bagging machine for down packing, or repackaging

Category | Bulk Bag Unloaders | Valve Bag Fillers |

This material transfer system conveys the contents of a bulk bag into 10 to 100 pound valve bags. It can be used to transfer materials such as powders or small granules including finish cement, bentonite, barite, fertilizers, frac sand, powdered limestone, gypsum, powdered iron ore, oil drilling chemical powders, titanium dioxide, and more.

Category | Bulk Bag Unloaders | Small Vibratory Feeders |

This big bag unloader discharges material from a bulk bag into an industrial mixer. An operator lifts a bulk bag using a fork truck and hangs it on the frame. Material is drawn out of the bag using an enclosed vibrating feeder and transfers it into a paddle mixer for blending with other dry ingredients. The feeder is controlled by a loss-in-weight system comprised of load cells and a controller to dispense a specific weight of material per batch.

Ask a Question or Get a Price Quote

Category | Bulk Bag Unloaders |

This bulk bag unloader meters and unloads crumb rubber from 2,000 pound bulk bags with a maximum height of 72 inches.

Category | Bulk Bag Unloaders |

This machine was designed to unload and dispense carbon black powder from big bags into buckets. After filling a bucket, a vibrating table was used to settle or densify the powder. The buckets were stacked onto pallets for transport to an industrial mixer for blending.

This machine was designed to unload and dispense carbon black powder from big bags into buckets. After filling a bucket, a vibrating table was used to settle or densify the powder. The buckets were stacked onto pallets for transport to an industrial mixer for blending.

This customer specialized in the production of lead powder, tin powder, and tin / lead alloy powders. Their products were used for many types of industries including oil and gas, radiological protective clothing, industrial x-ray shielding, anti-friction products, and batteries. All metal powders are manufactured, blended, and packaged per customer specifications.

Ask a Question or Get a Price Quote

Category | Bulk Bag Fillers | Bulk Bag Unloaders | Industrial Mixers |

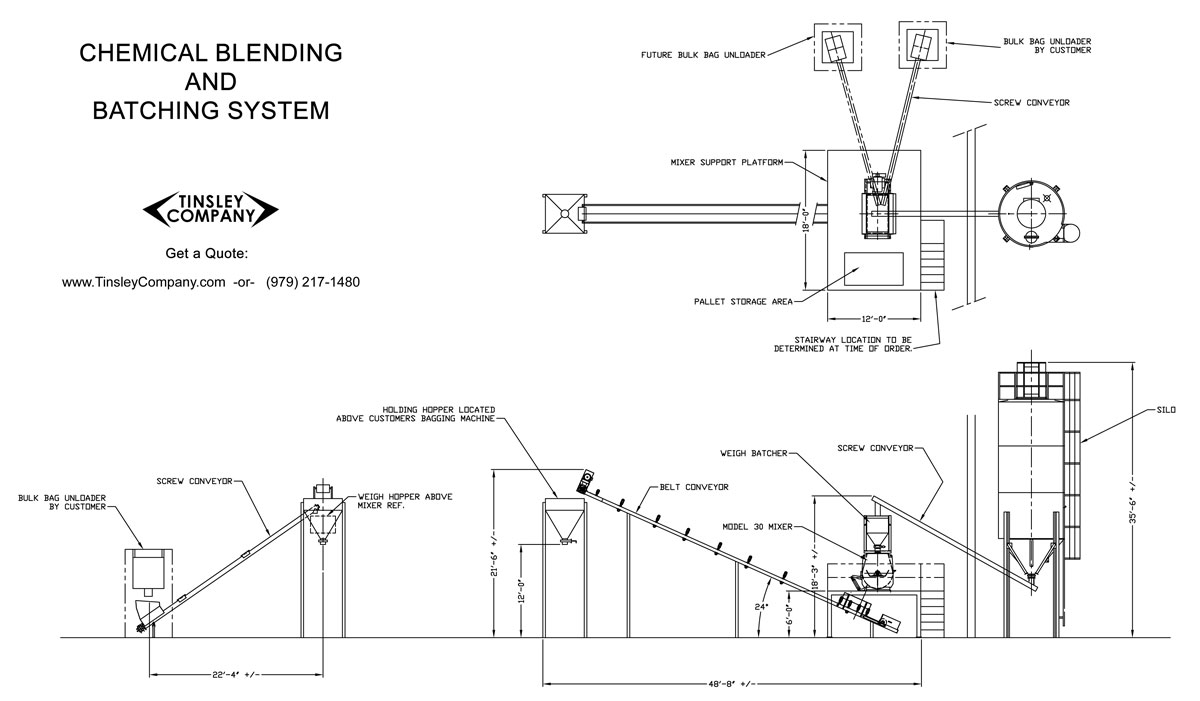

This chemical blending and batching system was used for the toll blending of powder chemicals, including calcium carbonate. The final blended product was to be automatically packaged into bulk bags using a bulk bag filling machine. It could also be packaged into smaller bags using a valve bagging machine.

Category | Bulk Bag Unloaders |

This bulk bag unloader dispenses poorly flowing, granular material directly from bulk bags into a valve bag filler. Then, the valve bag filler fills 40-50 pound bags. A vibrating hopper bin with untie hopper door provides agitation to promote the material transfer at a constant rate. Stairs and a working platform provide access to the bag untie door. The customer loads the bulk bag onto the unloader using a fork lift, but an optional self-contained hoist is available.

This bulk bag unloader dispenses poorly flowing, granular material directly from bulk bags into a valve bag filler. Then, the valve bag filler fills 40-50 pound bags. A vibrating hopper bin with untie hopper door provides agitation to promote the material transfer at a constant rate. Stairs and a working platform provide access to the bag untie door. The customer loads the bulk bag onto the unloader using a fork lift, but an optional self-contained hoist is available.

Ask a Question or Get a Price Quote

Category | Bulk Bag Unloaders |

This custom designed big bag unloader transfers Calcium Carbonate from bulk bags to downstream equipment using a screw conveyor. It was manufactured for a large U.S. plastics compounding manufacturer based in Texas. The system shown is designed to dispense and convey Calcium Carbonate, which has a bulk density of 30 to 80 pounds per cubic foot, at flow rates of 9,000 pounds per hour.

This custom designed big bag unloader transfers Calcium Carbonate from bulk bags to downstream equipment using a screw conveyor. It was manufactured for a large U.S. plastics compounding manufacturer based in Texas. The system shown is designed to dispense and convey Calcium Carbonate, which has a bulk density of 30 to 80 pounds per cubic foot, at flow rates of 9,000 pounds per hour.

Category | Bulk Bag Fillers | Bulk Bag Unloaders | Recycling Systems |

This material transfer system loads and unloads plastic scrap in bulk bags and boxes for recycling. The custom manufactured components included (3) bulk bag unloaders with vibratory agitation, (2) bulk bag filling machines (shown in picture), and (1) bulk box loader. After competitive testing, the bulk bag filling machines proved to be the only ones capable of effectively transferring the large, interlocking shreds of plastic scrap into bulk bags.

This material transfer system loads and unloads plastic scrap in bulk bags and boxes for recycling. The custom manufactured components included (3) bulk bag unloaders with vibratory agitation, (2) bulk bag filling machines (shown in picture), and (1) bulk box loader. After competitive testing, the bulk bag filling machines proved to be the only ones capable of effectively transferring the large, interlocking shreds of plastic scrap into bulk bags.