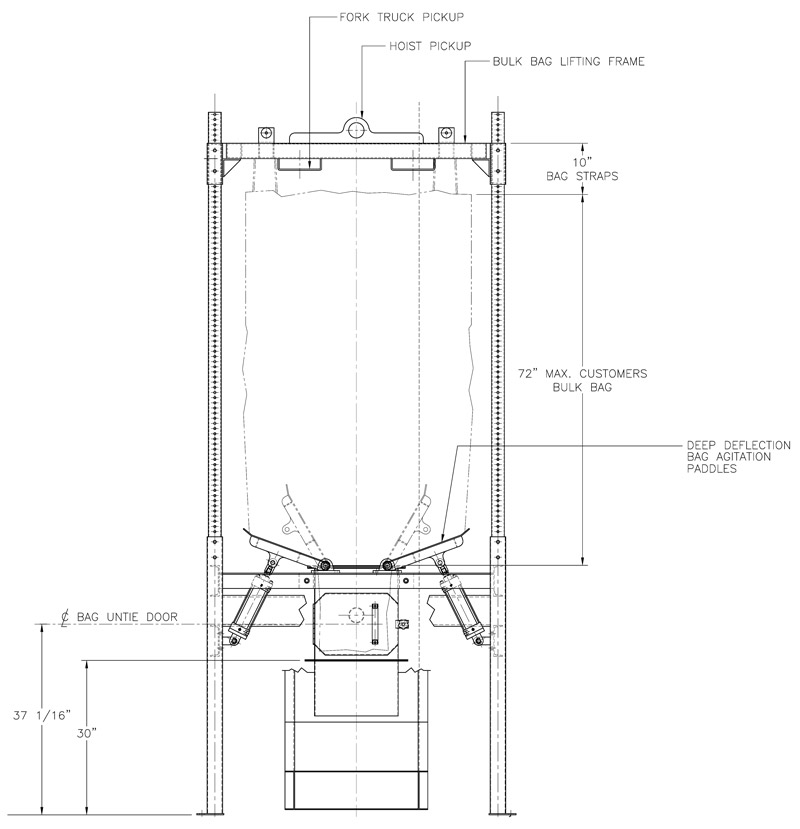

This bulk bag unloader meters and unloads crumb rubber from 2,000 pound bulk bags with a maximum height of 72 inches.

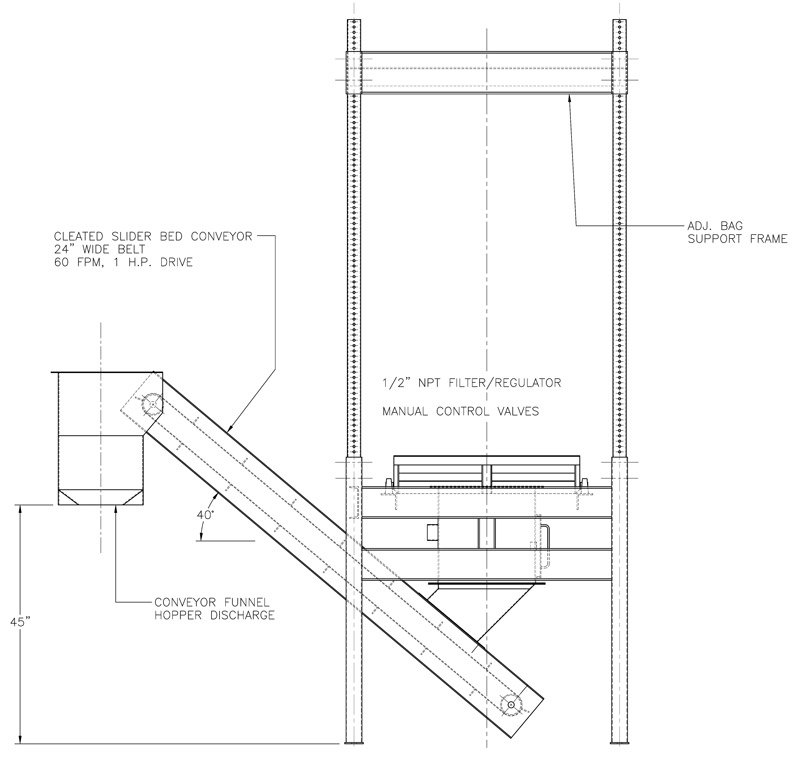

First, the bulk bags are placed inside the bulk bag unloader using a fork lift. Then the operator unties the bulk bag through the bag access door. Deep deflection, bag agitation paddles are used to promote the flow of crumb rubber from the bag to the conveyor below. The operator uses manual controls to start and stop the conveyor. The conveyor transports the material to a rolling bulk storage container for later use in the manufacturing process.

Due to low ceiling height in manufacturing facility, an incline belt conveyor was used to elevate material to the correct discharge height. The conveyor is a cleated slider bed conveyor with a 24 inch wide belt.