High-speed industrial mixer for powders

High-speed mixers designed to blend, condition, and mix

These high-speed industrial mixers are designed to quickly blend, condition, and mix large batches of products including powders, pharmaceuticals, refractory castables, spices and other types of products. They can also be engineered to process hazardous and non-hazardous dust and industrial bi-products for disposal that meets today’s stringent environmental laws and restrictions.

Ask a Question or Get a Price Quote!

Types of Industrial Mixers:

1. Industrial Food Grade and Sanitary Mixers

Stainless steel commercial mixer for mixing food grade products

Food grade mixers, or sanitary mixers, are used when sanitary construction is specified for food, chemical, and pharmaceutical products. They are built using a stainless steel product contact surfaces with a finish containing no cracks or crevices. The mixer interior can be polished up to a 120 grit final finish. They can be single or twin shaft mixers with either a ribbon or paddle agitators.

2. Pug Mills

Pug mill continuous mixer

These powerful pug mill continuous mixing systems process wet and dry materials at capacities ranging from 50 to 400 tons per hour. The dual mixing shafts operate independently with a separate motor, v-belt, and gear reducer composition for sequential starting.

Pug mill mixer with access doors open

Pug mill dual mixing shafts

Ask a Question or Get a Price Quote!

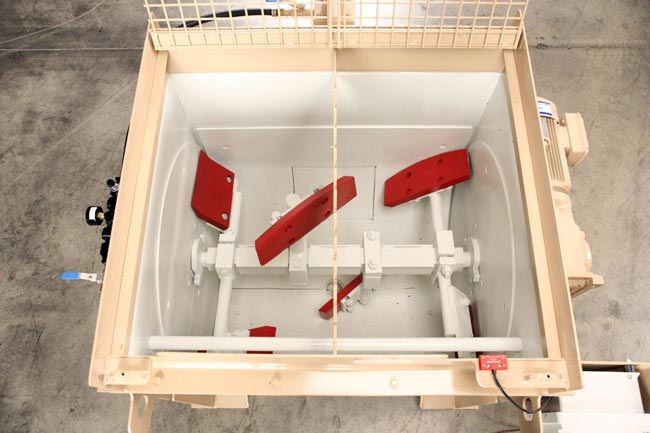

3. Paddle Mixers

Interior view of single shaft paddle mixer for dust processing

Paddle mixers are available with a single or double shaft. Single shaft paddle mixers process smaller amounts of dust or waste bi-products up to 8 tons per hour. Double shaft paddle mixers can handle very large batch mixing. Both types of paddle mixers can handle dusty, powdery, hazardous, and non-hazardous materials.

High-speed twinshaft paddle mixer used to process waste dust for removal

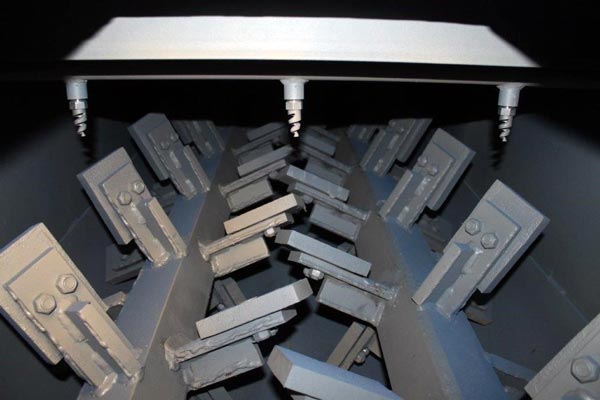

Interior view of high-speed twin shaft industrial mixer

4. Turbin Mixers

Turbin powder mixer

Turbin mixers are the most efficient and productive mixer for processing dust and other types of fine, dusty, powdery, hazardous, and non-hazardous materials. The three-dimensional mixing action produces a non-dusting material in as little as 30 seconds with as little as 8% water (or another reagent). There are 8 sizes available with dust processing rates of 8 to 200 tons per hour.

Interview of turbin dust and powder mixer

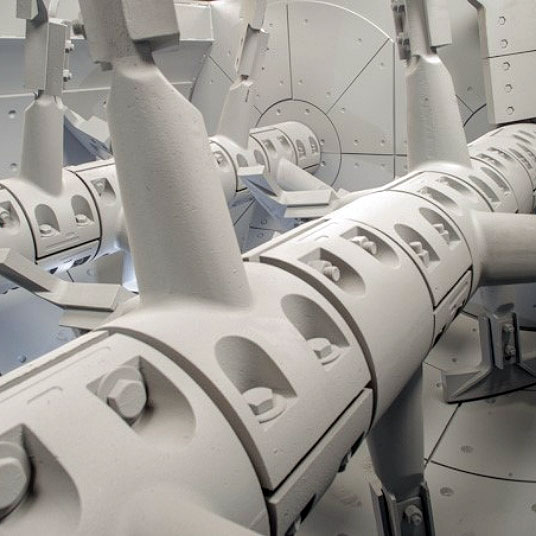

5. Refractory Mixers

Planetary style refractory mixer for industrial bulk processing

Refractory mixers are specifically designed to meet the needs of the refractory industry and refractory castables. These mixers have a low profile design and can fit into new or existing plants. They mix wet or dry batches of materials, irregular shapes, and sizes. They have an extremely fast mixing cycle because of the horizontal pan-type design and quick opening discharge door.

Industrial refractory mixer with horizontal shaft

Planetary style refractory mixer

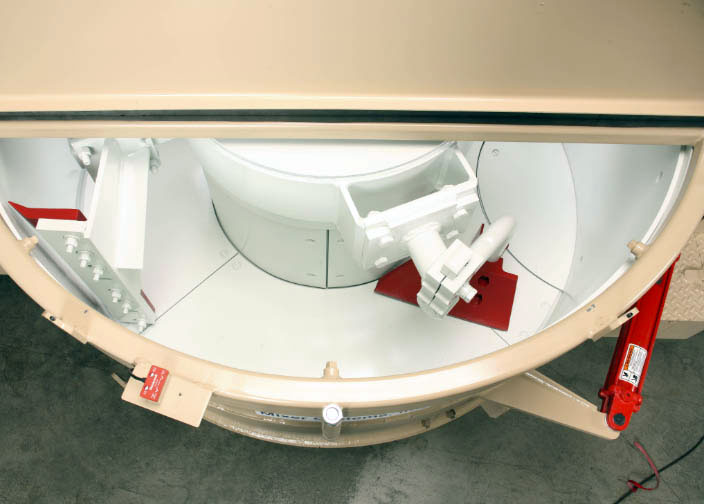

6. Planetary Mixers

Planetary mixer used to mix aggregate

Planetary mixers are a pan style mixer with counter rotating mixing arms to mix wet or dry material. A homogenous mix can be achieved in as little as 30 seconds. Up to four discharge doors are available for feeding material to different workstations.

Mixing spider with 3 paddles inside of a planetary mixer

« Back to Equipment and Systems

Ask a Question or Get a Price Quote!

Call: (979) 217-1480