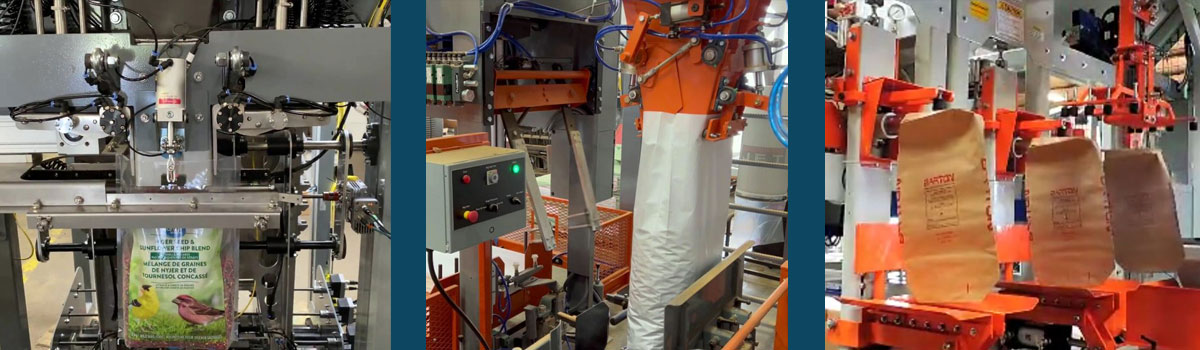

Automatic bagging systems for pouches, open mouth bags, and valve bags

Automatic bagging systems are typically used to fill and seal bags and pouches containing 1-110 lbs. of product. The systems can be categorized by the types of bags or pouches being filled.

Click a link below to jump to a section on this page:

Ask a Question -or- Get a Price Quote

Automatic Bagging Systems for Smaller Open Top Bags our Pouches

This type of automatic bagging system typically fills bags or pouches with 1-25 lbs. of product in a commercial packaging line.

Watch a Video:

Free-flowing and dry products are fed into the system from a surge hopper. Product flows from the surge hopper, through a gravity gate, and onto a vibrating pan feeder. Next, the vibrating feeder doses a set rate of product into the bagging machine. The simplex version of this bagging machine has an internal weigh hopper that is suspended from a single load cell. Once a set target weight of product has accumulated in the weigh hopper, it releases the product into a bag or pouch pneumatically clamped on the spout below. Depending on the bagging rate required, there might be one or many vibrating pan feeders dosing product into multiple internal weigh hoppers … simplex (12 bags/min), duplex (20+ bags/min), or triplex (30+ bags/min).

Bags and pouches are hung on the spout automatically using a bag placer. After filling, a shelf or scissor lift extends to catch the bag or pouch as it is released from the spout. An arm gently moves it onto a bag closing conveyor where a band heat sealer hermetically seals the bag. After sealing, the bags and pouches are conveyed to an automatic box filling pick-and-place robot or bag baler. These boxes or baler bags can then be palletized using a robotic palletizer and wrapped using a stretch wrapper. Filled pallets are retrieved from the system by a forklift operator for shipping or storage.

Watch a Video:

Automatic Bagging Systems for Larger Open Mouth Paper or Plastic Bags

This type of automatic bagging system typically fills open mouth paper, plastic, or poly woven bags with 20-110 lbs. of product.

Watch a Video:

Product is fed into the system from a surge hopper. Product flows by gravity from the surge hopper and into the bagging machine’s internal weigh hopper. When a fill cycle starts, product is discharged from the weigh hopper, through a funnel spout, and into the bag clamped to the spout below.

Depending on the flow characteristics of the product, vibrating feeders, belt feeders, or augers are used to add or “dose” product into a weigh hopper. Multiple weigh hoppers can be filled simultaneously to achieve higher bagging rates.

- High-speed net weigh bagging machines are considered the bagger of choice for high volume industrial bagging operations for free-flowing, granular products (80 mesh or coarser) up to 24 bags/min.

- Auger fed bagging machines are used for free-flowing, non-free flowing, and floodable powders. These types of machines are automatic gross weigh fillers that simultaneously fill and weigh product directly into the bag up to 10 bags/min.

- Belt fed gross weigh bagging machines are used for non-free flowing powders, granules, and flaky materials. When a fill cycle starts, product is conveyed with a specially designed belt feeder that conditions and delivers it to the weighing scale. When the target weight has been reached, the belt feeder will stop and the cutoff gate in the machine closes. This type of bagging machine can realistically achieve bagging rates of 8-10 bags/min.

An automatic bag placer retrieves an empty bag and places or hangs it on the bagging machine’s fill spout. A pneumatic bag clamp securely holds the bag to the spout during the fill cycle. After filling, the bag gently drops onto a bag closing conveyor. The filled bag is conveyed through an industrial bag sewing or heat sealing machine.

Next, the bag is knocked down, turned, and conveyed through a bag flattener that makes the bag more uniform in shape for palletizing. After flattening, the bag is moved through a series of conveyors that square and index it before arriving at the robot pick conveyor. A robotic arm using a bag tool lifts the bag, swivels, and stacks it on a shipping pallet in a pre-configured stacking pattern at rates up to 20+ bags/min.

Multiple pallets can be stacked in one system on either side of the robot. Empty pallets are conveyed into the bagging system using an automatic pallet dispenser. An automatic slip sheet dispenser applies a slip sheet before it arrives at the robot for palletizing.

Filled pallets are conveyed to an automatic stretch wrapper that turn and wrap the bags and pallets to secure them in place. Then, the wrapped pallets are conveyed to the end of the packaging line where a forklift operator retrieves them for shipping or storage.

Watch a Video:

Automatic Bagging Systems for Valve Bags

This type of automatic bagging system typically fills paper and plastic valve bags with 20-100 lbs. of flakes, granules, or powders. Valve bags are self-sealing or self-closing and usually do not require a bag closing heat sealer or sewing machine. However, some products do require that the valve be hermetically sealed using an ultrasonic sealer for freshness.

Automated valve bag tip and drop onto conveyor

Product is fed to one or more valve bag filling machines. An automatic bag placer, or robot, lifts an empty bag from the bag indexing conveyor and opens up the valve or sleeve on the bag. Once the valve has been opened or formed, the robot places the bag onto the filling spout of the bag filling machine and the filling cycle starts.

The bag clamp is activated to hold the bag on the fill spout and an inflatable valve seal provides a tight connection between the fill spout and the bag during the fill cycle. The scale is tarred to zero and the internal auger, air pressure chamber, or impeller moves product into the bag. Most of the fill cycle is completed at a high filling rate. As the set target weight nears, the dribble flow feature is automatically activated, slowing the fill rate to complete an accurate fill of the bag.

Next, the automatic bagging system removes the filled bag from the spout for sealing. The sealing process uses an ultrasonic bag sealer to squeeze and activate the pre-applied adhesive on the end of the bag’s sleeve creating a hermetic seal. Once sealed, the bag is discharged onto a bag takeaway conveyor for palletizing.

The bag will now move through a series of conveyors that will orient and flatten it for palletizing by a robotic palletizer. After flattening, the bag is moved through a series of conveyors that square and index it before arriving at the robot pick conveyor. A Fanuc or Kawasaki robotic arm using a bag tool lifts the bag, swivels, and stacks it on a shipping pallet in a pre-configured stacking pattern at rates up to 20+ bags/min.

Multiple pallets can be stacked in one system on either side of the robot arm. New pallets are conveyed into the automatic bagging system using a pallet dispenser. An automatic slip sheet dispenser applies a slip sheet before the pallet arrives at the robot for stacking.

Watch a Video:

Filled pallets are conveyed to an automatic stretch wrapper that turn and wrap the bags and pallets to secure them in place. Then, the wrapped pallets are conveyed to the end of the packaging line where a forklift operator retrieves them for shipping or storage.

Ask a question or get a price quote!

Call: (979) 217-1480