This automatic plastic pellets bagging system fills 50 lb. poly bags at a continuous rate of 12-14 bags per minute with pellets that are used in various extrusion processes.

This automatic plastic pellets bagging system fills 50 lb. poly bags at a continuous rate of 12-14 bags per minute with pellets that are used in various extrusion processes.

Both the bag placer and bag top reformer can operate in automatic or manual modes, allowing the system to continue to operate, even during maintenance or repairs of this equipment. Other automated systems do not allow for this type of feature and the entire packaging line must be shut down.

This type of packaging system can be used to pack plastic granules, or more slightly irregularly shaped free-flowing particles that are used in processing recycled plastics.

Process Description

Process Description

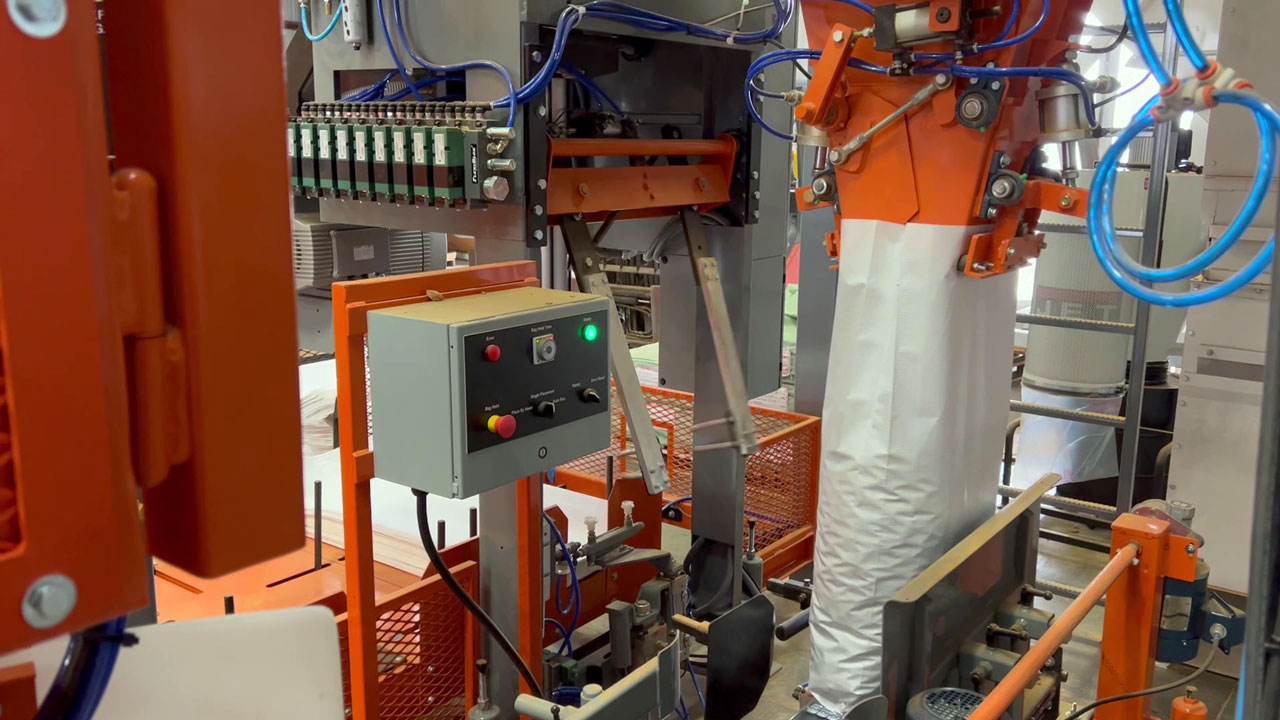

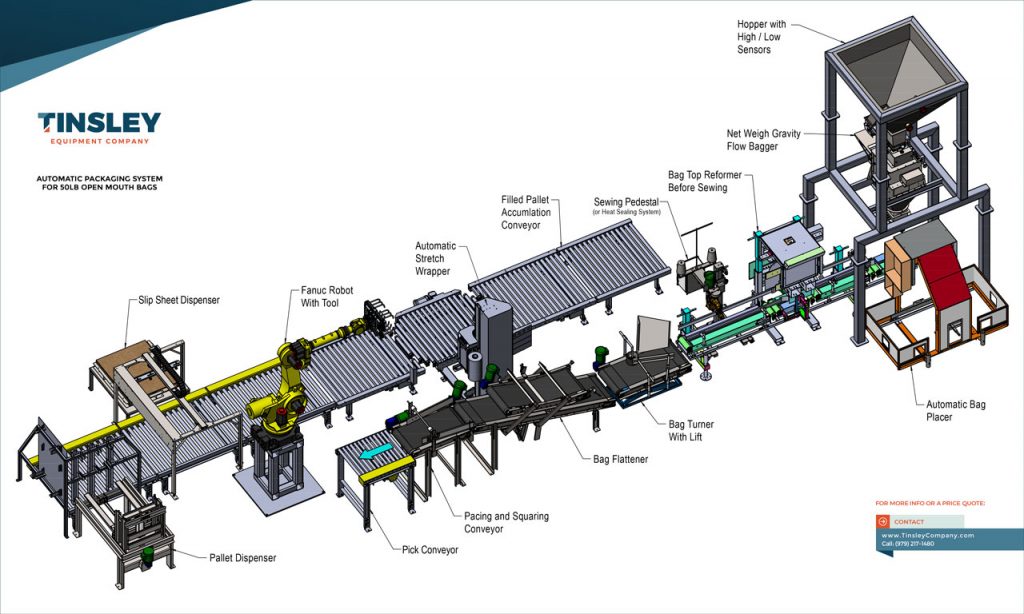

Free-flowing plastic pellets are conveyed to a 100 cubic foot hopper with scale support frame using a pneumatic conveying system. The plastic pellets flow freely into a simplex net weigh bagging scale attached to the hopper that includes a gravity gate feeder, vibratory feeder, and dust tight bag spout.

An automatic bag placer hangs a poly bag on the bag spout and the bagging scale’s internal weigh hopper releases 50 lbs. of plastic pellets or granules into the bag. Once the bag has reached the set target weight and the plastic pellets have been packaged into the bag, the pneumatically powered bag clamp releases the filled bag onto a bag closing conveyor below.

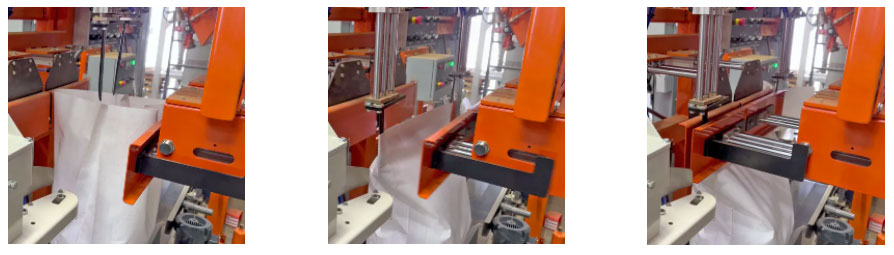

The bag is conveyed through a bag top reformer that includes a fill zone support conveyor with bag centering that stretches and reforms the bag’s top before moving through a continuous band heat sealer.

After sealing, the bag moves over a knockdown bag turning conveyor that positions the bags print side up to travel bottom first into a bag flattening incline conveyor.

After flattening, the bags arrive at squaring and accumulation conveyor where a Fanuc robot gently picks up the bag and stacks it on a pallet that is placed by an automatic pallet dispensing system.

Once the robot fully stacks pallets, they move to a turntable automatic stretch wrapper. After wrapping, an operator uses a forklift to remove the stretched wrapped pallets from the system for shipping or storage.

Process Description

Process Description