Learn more about industrial dust suppression systems and dust control methods for use during the processing and handling of dry bulk solids at indoor facilities or outdoor plants.

Dust suppression and curtain systems used during loading of trucks with dry powder to be transported to a landfill for disposal

What is industrial dust suppression and what are some dust suppression methods?

Dust suppression systems are used to prevent, control, and greatly reduce the amount of fugitive dust particles (usually smaller than 10 microns) released during the processing and handling of dry bulk solids. This is generally done by wetting or spraying the ultra-fine dust particles with water, or by mixing water with a dust control chemical like magnesium chloride. The spray clings to the dust particles and causes them to drop or fall out of the air.

This is different from dust collection methods that use vacuums, baghouses, fabric filters, wet scrubbers, electrostatic precipitators, water curtains, and dust collectors.

Some industrial dust suppression methods include:

- misters, water curtains, and dust control sprayers

- chemical dust suppression systems (surfactant chemicals added to water to reduce droplet size)

- conveyor dust covers and flow control chutes

- fog cannons

- dust suppression systems

- continuous dust monitors

Where are industrial dust suppression and control systems used?

Dust suppression systems are used at interior and exterior locations in the following types of industries:

- Grain and food processing – wheat, flour, sugar, spices

- Packaging and bag filling

- Power generation

- Mining and crusher plants

- Cement

- Foundry

- Aggregate, sand, and frac / silica sand processing and screening

- Pulp, paper, and wood

- Construction and demolition

- Recycling

- Agriculture – barns, silos, warehouses

- Shipping, rail, and trucking

Dust suppression system used on a hopper

They are used to control dust at conveyor transfer and discharge points, crushers, truck dump stations / tippers, train rail car loading / unloading, hoppers, vibratory screens, feeders, reclaimers, ship loaders / unloaders, ash conveyors / discharge chutes, warehouses, and more.

Dust suppression system used while loading cargo ships with coal

What is a dust suppression system and how does it work?

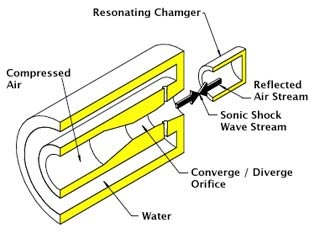

Dry Fog dust suppression systems use a special air-atomizing nozzle that produces a very dry fog to remove dust particles from the air. They are sometimes called foggers, ADS, dry fog systems, sonic dry fog systems, ultra-sonic fog, or air atomizing water spray systems.

Detail of a Dry Fog air-atomizing spray nozzle

They use simple compressed air and plain water to produce a true fog consisting of droplets 1-10 microns in size. These ultra-fine droplets attach to similar sized dust particles. The wetted dust particles become heavy enough to be removed from the air and fall back into the processing or handling area.

How is a Dry Fog dust suppression system different from using misters or dust control sprayers?

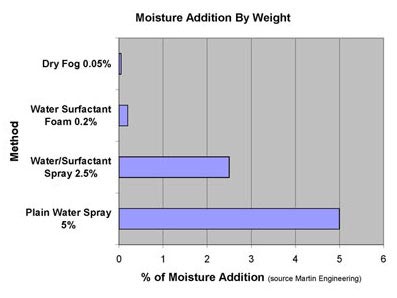

The Dry Fog dust suppression system only wets the dust and NOT the material being processed or handled. This results in very low water and power requirements. It also does not require expensive chemicals or wetting of the product, typically no more than 0.1% moisture addition.

Moisture addition by weight for Dry Fog vs. dust sprayers

The Dry Fog systems meet all requirements for explosion hazardous areas. Freeze protection can also be included for dust control in temperatures as low as -35℉ due to a phenomenon known as “cloud physics.” This is because dry fog droplets will not freeze due to their lack of mass.

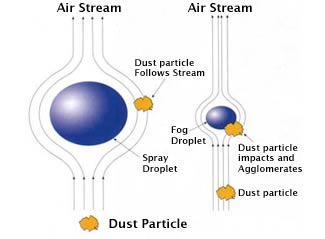

Misting and dust spraying systems are NOT fog systems. The larger droplets produced by these types of methods range from 20-100 microns in size and have been proven to be ineffective in treating airborne dust particulates due to a principle called the “slip stream effect” created by the water droplet being larger than the dust particle.

Dust mister or sprayer droplet vs. a Dry Fog droplet

How does a Dry Fog dust suppression system compare to a fog cannon?

Fog cannons are essentially snow making machines and can only produce droplet sizes of 90-300 microns in size, which is essentially a fine drizzle. Fog cannons require much more water ranging from 12-30 gallons per MINUTE.

Dry Fog systems create particles in size ranging from 1-10 microns. Dry fog dust suppression systems require much less water, ranging from 3-13 gallons per HOUR. A dry fog system can cover the surface area of 1/2 a football field with fog using only 1 gallon of water!

How much does a Dry Fog dust suppression cost to operate?

Operating costs are much lower than dust collection or chemical spray systems…up to 4 times less! There are no chemicals to buy, no moving parts to replace, and lower energy costs.

Dry Fog dust suppression system with wind fences installed on top of a hopper

How much does it cost to install a Dry Fog dust suppression system?

Installation costs are also lower using an easy-to-install modular system. Most customers are able to self-install their own systems. Everything is pre-wired and mounted to a common galvanized steel frame. Hard piping for air and water supply lines are also eliminated by using instrumentation tubing housed inside a flexible protective conduit. All nozzles mounts bolt on at their application point, so no welding is required.

Have a question or need a price quote?

Call (979) 217-1480 -or- use our Express Contact Form

Learn more about Dry Fog Dust Suppression Systems.