Commercial producers seasoning tortilla chips and potato chips can benefit greatly from the use of electrostatics to evenly apply dry spices, powders, seasonings, and oils. This type of seasoning system provides up to 98% coating efficiency of all chip products, while using 10-45% less dry powder seasonings. It also dramatically reduces the amount of airborne dust and seasoning, which results in a much cleaner working area, cleaner seasoning drum, and less line contamination.

Seasoning tortilla chips and potato chips tumbling in rotating drum

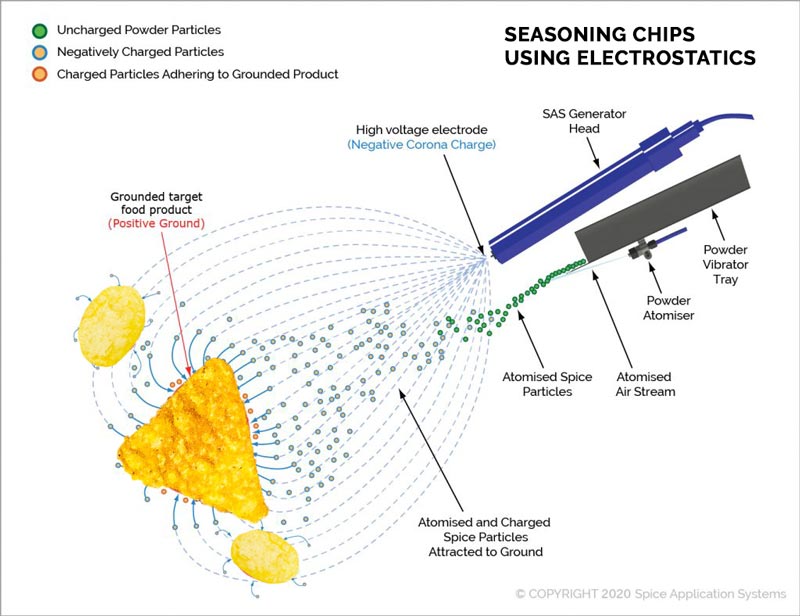

How an electrostatic seasoning system works

Up to 98% Coating Efficiency with 10-45% Powder Savings!

How the electrostatic seasoning application system works:

- Tortilla or potato chips discharge out of a fryer and onto an incline conveyor.

- The incline conveyor gently transitions and meters the chips into a grounded / positively charged rotating seasoning drum (also called a flighted enrobing drum).

- The rotating drum positively charges the chips and conveys them toward the seasoning application equipment.

- Powder seasoning is dispersed using a vibratory feeder and an air knife that blows the seasoning through a negatively charged field.

- The powder seasoning is attracted to the positively charged chips and evenly coats them creating a true wrap around effect.

- The seasoned chips discharge out of the drum and onto a takeaway conveyor for packaging.

The electrostatic seasoning equipment can be retrofitted onto existing machines or purchased as part of a completely new production line. It is also used to evenly coat different types of snack food products like rice cakes, peanuts, pretzels, cashews, cookies, cereal, cheeses, and pet food.

Watch a Video:

Try before you buy! Product testing is available.

Contact us today to set up a test to see how electrostatic food coating technology can reduce your production costs and increase product consistency.

Related Video:

Potato chips coated with a light amount of seasoning, oil, and other flavorings