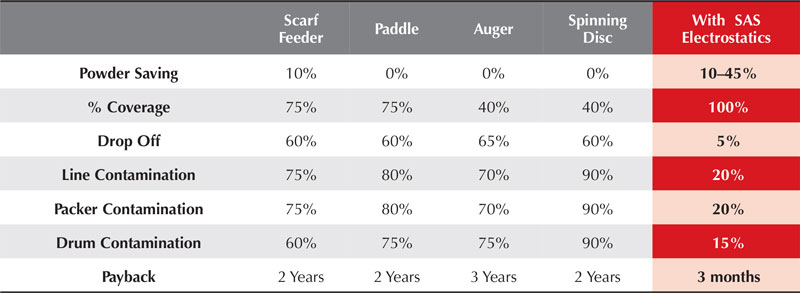

Apply seasoning, spices, sugar and other coatings to peanuts and snack products using electrostatic technology for up to 45% seasoning reduction. It has been used with peanuts, cashews, macadamia nuts and many other types of fragile snack products like chips, pretzels, pastas, rice, cheese and more.

This type of spice application system can be installed on new or existing machines and systems.

Complete systems are also available for testing purposes to use on-site before final purchase. Contact us for more information about setting a test system at your production facility.

Watch a Video:

This type of seasoning machine and equipment can be added to all types of pump, screw feeders and vibratory feeders. It has also been added to existing rotating drums or enrobers as shown in the test videos. It can be easily configured for the application of oil and powder from the control panel.

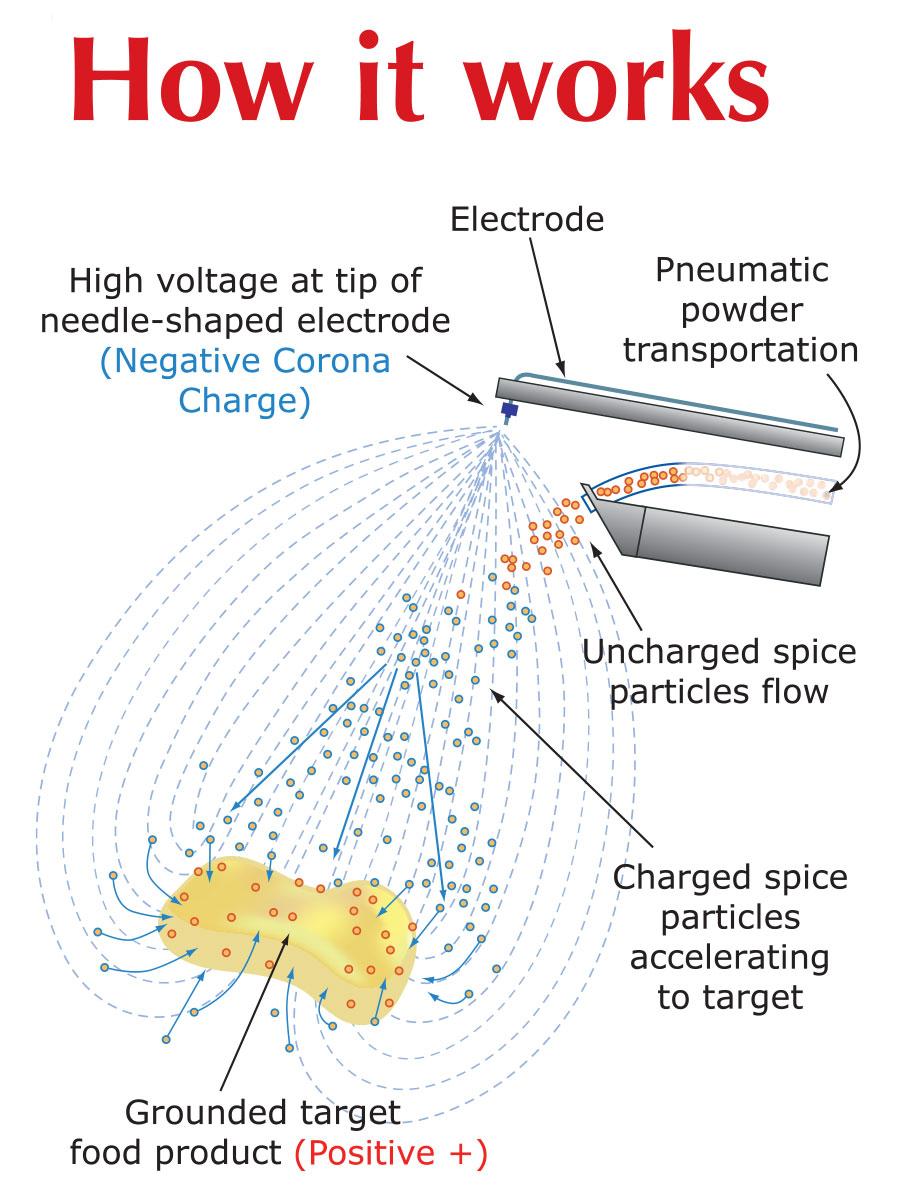

The electrostatic technology applies a static charge to the flavorings such as seasoning, spices or sugar as it is sprayed onto the peanuts or snack products. As the flavorings and coatings become negatively charged, they adhere automatically to the positively charged peanuts or snack products. This creates a true wrap around effect that results in up to a 98% coating efficiency and a high quality snack product.

The electrostatic coating process drastically reduces the amount of seasoning powder and increases energy efficiency. Powder contamination and misting is greatly reduced resulting in a cleaner working environment with less dust and downtime for cleanup and product changes.

Have questions or need a price quote?