Choose from different types of nut bagging equipment that automatically weigh and fill pouches, sacks, and bags with different types of raw or roasted nuts. These packaging machines are used for filling bags with many different types of snack nuts including peanuts, almonds, cashews, chestnuts, hazelnuts, macadamia nuts, pecans, pistachios, and walnuts.

Choose from different types of nut bagging equipment that automatically weigh and fill pouches, sacks, and bags with different types of raw or roasted nuts. These packaging machines are used for filling bags with many different types of snack nuts including peanuts, almonds, cashews, chestnuts, hazelnuts, macadamia nuts, pecans, pistachios, and walnuts.

Fill small pouches that weigh 0.5 – 5 lbs, large open mouth bags that weigh 10 – 50 lbs, or bulk bags that weigh up to 4,400 lbs. All nut bagging equipment has an accuracy of +/- 0.5-1% of target weight and can operate at different bagging speeds. Bag sealers automatically vacuum seal pouches for retail sale in stores, as well as for online sales at stores like Amazon. Nitrogen gas flush sealers are also available for sealing pouches or bags filled with nuts. Larger, 5-50 lb open mouth bags for wholesale can be sealed on a conveyor using a heat sealer or bag sewing machine and then palletized using a robotic palletizer.

Click a link to jump to a section below:

- Mid-level: fill small bags and pouches up to 25 lbs. with or without automation

- Larger Wholesale: fill 10-50 lb. bags with or without automation

Mid-level Nut Bagging Equipment: Fill bags and pouches with 1-25 lbs. of Nuts

For larger companies and contractors looking to fill bags and pouches with nuts using a larger packaging system, we recommend a small net weigh bagging scale. This type of bagging equipment quickly fills bags and pouches with 1-25 lbs. of dry, free-flowing products. The standard small net weigh bagging scale includes a gravity gate, single vibrating pan feeder, and a weigh hopper that is suspended from a single load cell. It is available in multiple configurations for high-speed commercial packaging systems.

For larger companies and contractors looking to fill bags and pouches with nuts using a larger packaging system, we recommend a small net weigh bagging scale. This type of bagging equipment quickly fills bags and pouches with 1-25 lbs. of dry, free-flowing products. The standard small net weigh bagging scale includes a gravity gate, single vibrating pan feeder, and a weigh hopper that is suspended from a single load cell. It is available in multiple configurations for high-speed commercial packaging systems.

Use a semi-automated or automated net weigher to fill pre-formed open mouth bags, stand up pouches, or doypacks constructed of paper, plastic, or poly-woven materials.

Watch a Video of this Type of Equipment

Wholesale Nut Bagging Equipment: Fill 1-24 Large Bags per Minute

Bulk container filled with raw nuts is dumped into bagging system

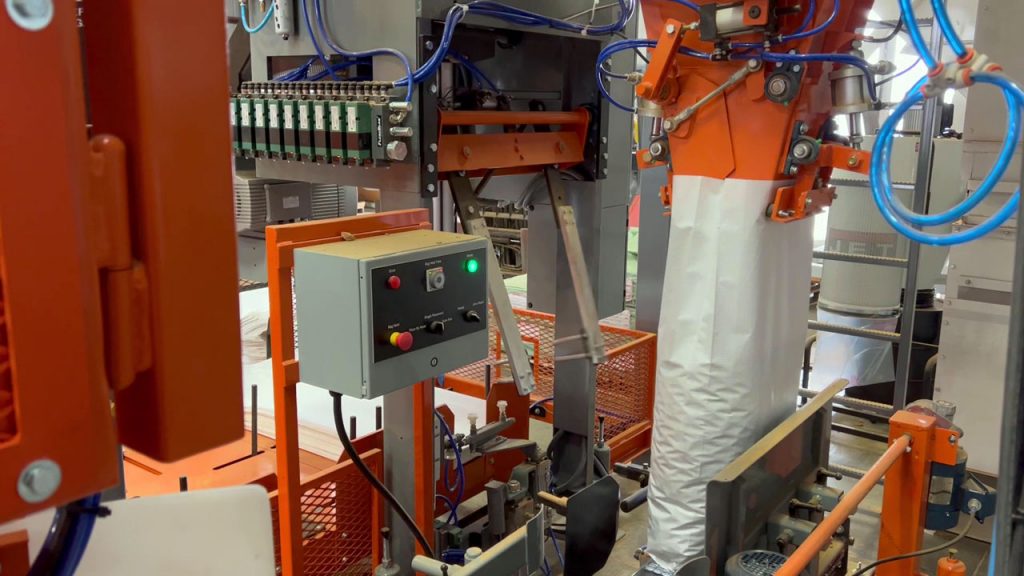

For quickly packaging nuts into larger 10-50 lb bags for wholesale, we recommend using a net weigh bag filler that can fill a variety of open mouth bags. This machine automatically fills a hopper, while a bag on the spout is being filled below, thus providing a much faster fill rate. For an entry-level wholesale nut bagging system with fill rates of 1-8 bags per minute, we recommend a digital gravity gross weigh filler.

Automatic bag placer spouts a bag and net weigher fills the bag with 50 lbs of nuts

Once the bag is filled, it is placed on a closing conveyor, where it is moved through a bag sewing machine. These type of machines can also print tracking and freshness codes onto the bag at the same time.

Bag moves through an automatic bag top reformer and into the bag sewing machine

After sewing, the packaged nuts are conveyed to a palletizing station, where a robotic palletizer or operator uniformly stacks them on a pallet for shipping. From there, the pallets are moved through a pallet stretch wrapper and onto storage or shipping.

Watch a Video of this Type of Equipment