Demand for crushed stone, sand, and gravel has grown over 3% annually from 2016 to 2021*. Tinsley Equipment Company has been a trusted supplier of bagging and material handling equipment needs for customers across the U.S. In the first quarter of 2021, our team helped a customer in Alabama with both their limestone and pigment powder bagging needs.

Bagging Limestone Powder

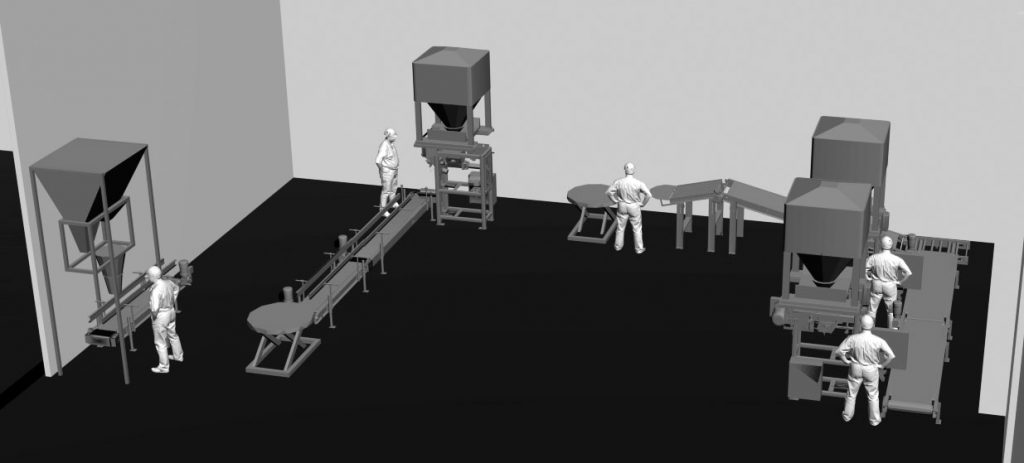

(2) Impeller valve style bagging machines capable of 8 x 50 pound bags per minute (per machine)

- Digital controls with 0.5% weight accuracy and 100 custom recipe capacity for unique target fill weight and parameter retention

- Discharge, incline, and transfer conveyors for manual bag stacking of filled bags on pallets

Pigment Powders

(1) Net weigh (pre-weigh) open mouth style bagging machine capable of 10 bags per minute

- Filling 5-10 pound bags

- Discharge conveyor with and industrial easy-lift system for palletizing filled bags

(1) Open mouth auger valve style bagging machine capable of 4 bags per minute

- Filling 25-50 pound bags

- Discharge conveyor to move the filled bags to the pallet for manual loading

The term pigment covers a wide range of materials and brings with it a host of handling challenges. This customer has over 200 variations to offer its wide customer base, and the bulk density and material properties range from 50 -85 lb./ft3. The customer utilizes intermediate bulk containers, or IBC’s, to move product from its mixing room into the bagging stations to enable quick-ship products.

In the Fall of 2020, the plant was running at near capacity to meet its customer demands. Our client needed to move from a manual process to a more automated solution. The Tinsley Equipment Company team performed a site laser scan of the packaging building to help in the product selection and equipment layout. After the equipment was delivered, the Tinsley team assisted in the start-up, training and on-going support that makes for a strong relationship.